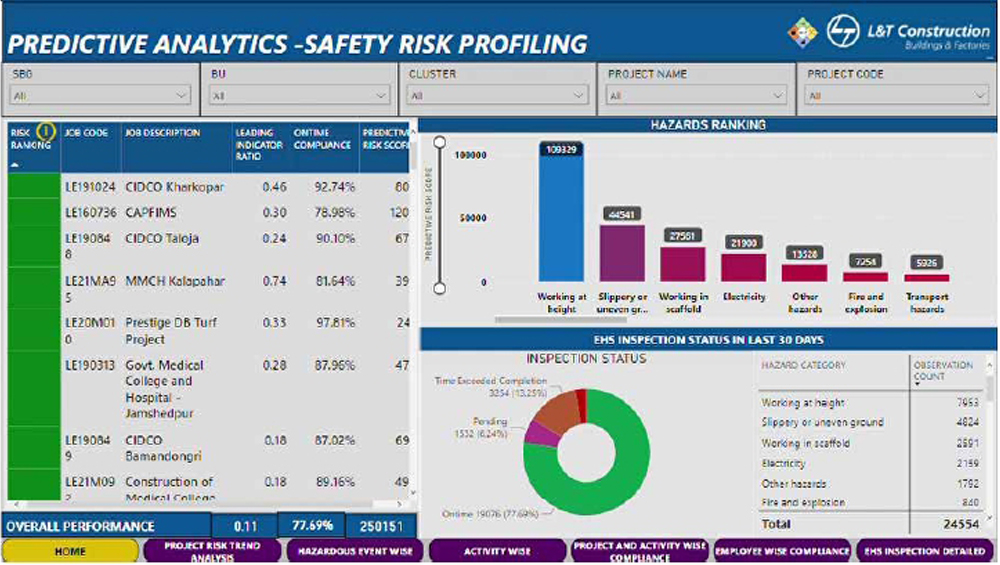

B&F’s Safety Risk Profiling – Predictive Analytics model taken to the next level

After the successful launch of B&F’s Safety Risk Profiling – Predictive Analytics, 760 senior leaders at HQ, clusters, & projects were trained on its usage. Based on user feedback and the IC’s plan for a second phase, the Risk Profiling Model and dashboards have been upgraded to the next level with a ‘Version 2.0’.

“The broad framework of the programme is based on the PDCA model of ISO 45001 and applicable to all types of operations including projects, manufacturing facilities, etc.,” reminds P Nagarajan, Head – EHS, HRC SBG, B&F IC, “and it can be successfully integrated irrespective of the level of digital implementations at various businesses.”

The broad framework of the programme is based on the PDCA model of ISO 45001 and applicable to all types of operations including projects, manufacturing facilities, etc., and it can be successfully integrated irrespective of the level of digital implementations at various businesses.

P Nagarajan

Head – EHS, HRC SBG, B&F IC

The projects are ranked into 4 categories: Very High, High, Medium, & Low Risk Potential, and the predictive risk score is arrived at using the advanced data analytics model, Principal Component Analysis (PCA). Mohd. Moizuddin, Head – EHS, PAF SBG, B&F IC, mentions that it is a self-learning module. “B&F is the first adopter within L&T Construction of this auto PCA ranking using the available digital data of the number of EHS Inspections raised and their compliance status along with the number of near-miss cases captured per workman,” he explains.

B&F is the first adopter within L&T Construction of this auto PCA ranking using the available digital data of the number of EHS Inspections raised and their compliance status along with the number of near-miss cases captured per workman.

Mohd. Moizuddin

Head – EHS, PAF SBG, B&F IC

Manifold advantages: The Predictive Analytics tool can be used to review the trend of risk scores, inspection compliances, and leading indicators. “Project & Cluster Heads can now review the top five activities and top five hazardous events at projects, based on the predictive risk score,” informs M Nachiappan, Senior DGM – EHS, B&F IC, “which enables them to prioritize those activities by enhancing resource deployment and supervision with more focused monitoring and review.” The EHS Inspection compliance of every Section In-charge and Site Engineer can be monitored in real time, which empowers Project/Cluster Heads to make informed decisions on counselling the respective staff members to help enhance their EHS performance.

Project & Cluster Heads can now review the top five activities and top five hazardous events at projects, based on the predictive risk score which enables them to prioritize those activities by enhancing resource deployment and supervision with more focused monitoring and review.

M Nachiappan

Senior DGM – EHS, B&F IC

A unique solution: Primary research has revealed that no such model exists globally, and it is based on the fundamental safety concepts like the Heinrich ratio & ISO 45001. The model continuously adapts on a realtime basis based on live data. “PCA is being used for the first time in L&T Construction,” remarks a visibly proud Moizuddin, adding that considering its complexity & uniqueness, the model has been developed after multiple iterations and trials.

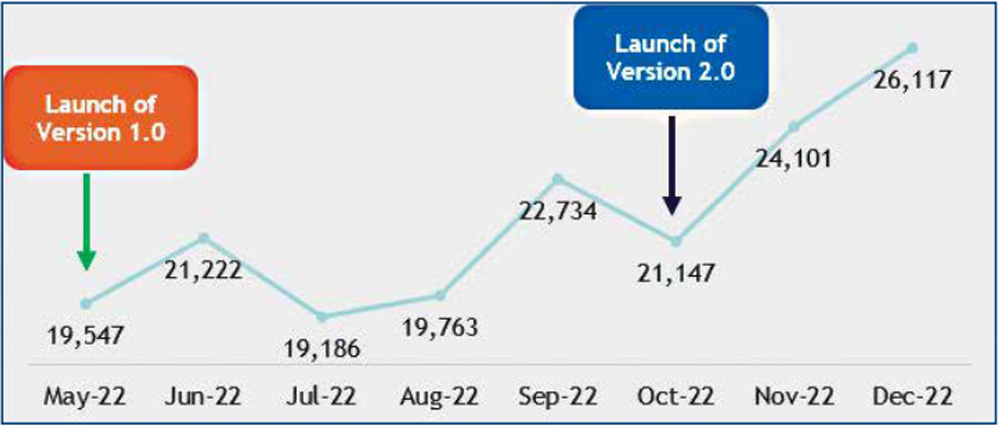

Certainly, the model is an important tool for leaders in our Mission Zero Harm, with projects ranked based on their risk potential considering multiple parameters. It also offers data-based safety risk profiling by prioritizing hazards and activities based on their risk profile. Both macro & micro views are available with a drill down to granular levels including employee-wise data. It will enable leaders to give priority in terms of resources, training, and review. Nachiappan adds, “There has been a 24% increase in the number of observations reported since the launch of Version 2.0 in October 2022.”

A 24% increase in the number of observations reported since the launch of Version 2.0 in October 2022

Not surprisingly, the initiative won the B&F Innovative Digital Solution award, followed by the Digital Excellence Award across the L&T Group.

Scalability across L&T: As a best practice, the success of the model depends on its scalability and how projects across L&T can reap its benefits. “The model has been implemented at all B&F projects and has also been approved by the EHS Council,” says a confident Nachiappan.

While it is due to be presented in the forthcoming ECOM by the EHS Council for implementation across the L&T Group, the model is versatile enough to work independent of any IC-specific digital ecosystem and maturity level of digitalization, and is applicable for all businesses. “We are presently busy preparing a road map with the central digital team and all IC digital & EHS teams for a group-level rollout,” concludes Nagarajan.