WHY IS IT SO IMPORTANT TO MIND YOUR HEAD?

The helmet — a lifesaver!

In November 2014, the cricketing world was plunged into gloom at the sad demise of young Australian cricketer, Phillip Hughes. Hit on the back of his head when ducking into a nasty bouncer, he collapsed on the field and later died without regaining consciousness. While the incident triggered frenzied re-designing of cricket helmets by introducing neck pieces, it yet again underscored how critical it is to keep one’s head well protected. The head is perhaps the most vital part of the human body housing all our major sensory organs, most important being the brain, that plays the role of a centralized conveyor of all information. An unhealthy brain renders one pretty much useless and hence it pays to mind your head!

We lead by example; our workmen are always watching us and will emulate whatever we do and so by strictly following safety protocols, we ensure that they follow them too.

N Ramesh Kumar

EHS In-charge, Medigadda Barrage project

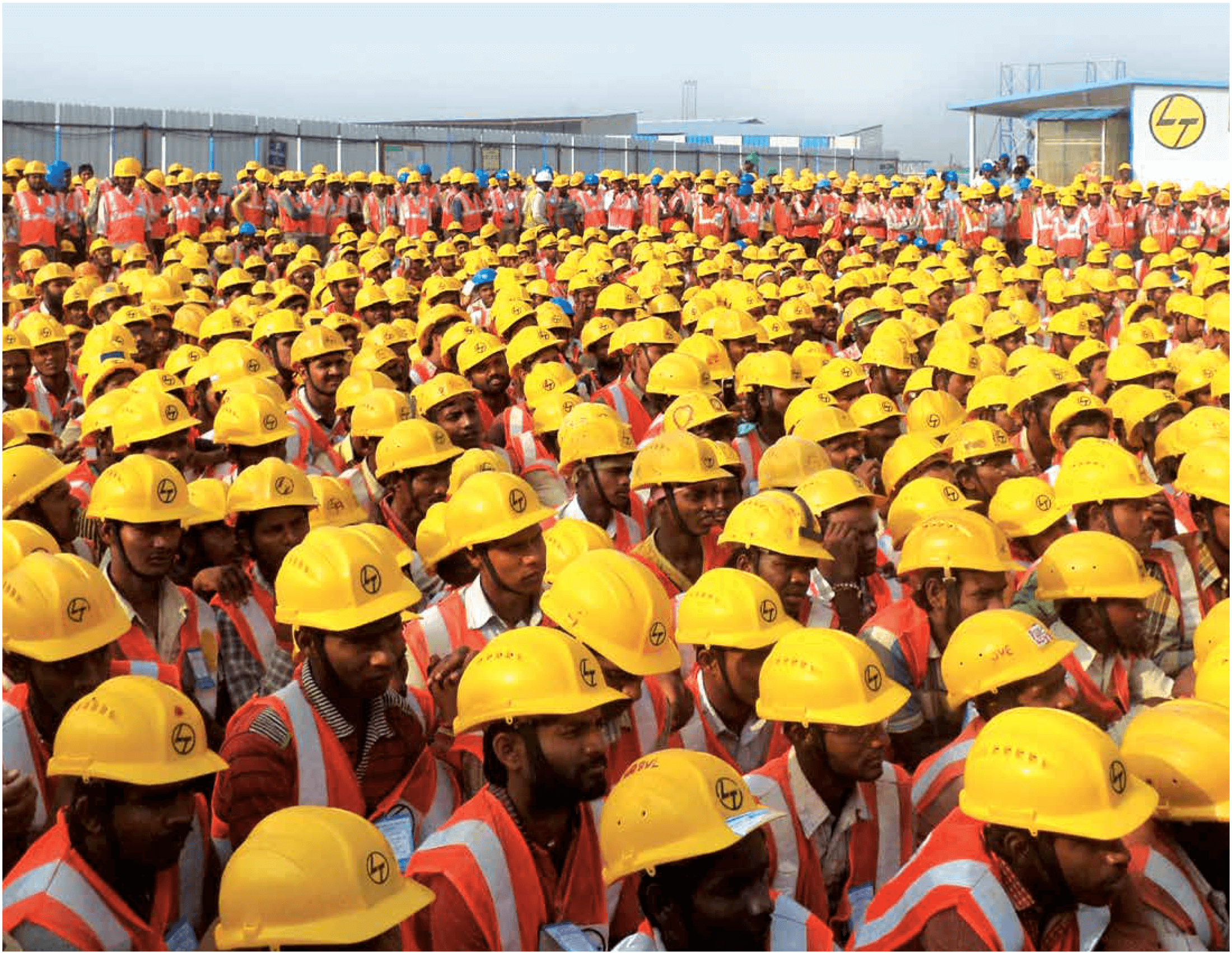

Day in and day out we read about fatal road accidents, largely involving bikers, not wearing helmets. Very often, people foolishly do not wear helmets either because they are too uncomfortable in our warm climes or are too cumbersome to carry; some just don’t think its stylish enough to have this head gear. The consequences can be very serious. Such foolhardiness must be avoided at construction sites at all costs. “Everyone, and we mean everyone, has to have a helmet at site,” declares Head – EHS, WIPRO SEZ site, R V Sudhakar, “because by allowing some people not to follow our rules is perhaps the worst way to impose discipline.” EHS In-charge, N Ramesh Kumar, who recently successfully completed the huge Medigadda Barrage project incident free, echoes similar sentiments. “We lead by example; our workmen are always watching us and will emulate whatever we do and so by strictly following safety protocols, we ensure that they follow them too.”

The evolution of the ubiquitous Helmet

Although helmets had been in use for several decades, its earliest avatar in the construction industry was the ‘Hard Boiled’ hat introduced in the 1920s, which itself was a variation of the tin hats worn by American soldiers during the first World War. Made of steamed canvas, glue, a leather brim and black paint, hard boiled hats were first made compulsory at the Golden Gate Bridge project in San Francisco, USA. A couple of decades later, entered the aluminium hard hats. These were, however, short-lived as aluminium, being a good conductor of electricity, was a poor choice and hence was replaced by three-rib, heat-resistant fiberglass hard hats that were later replaced by thermoplastics, a better and more economical alternative. Since the early 1980s, hard hats have evolved with the use of lightweight, durable polyethylene plastic that conduct electricity. These were later fitted with easy-lock snaps, enhanced brow pads and even vented hard hats. In fact, there are some helmets that come with built-in fans and even 3D hologram capability!

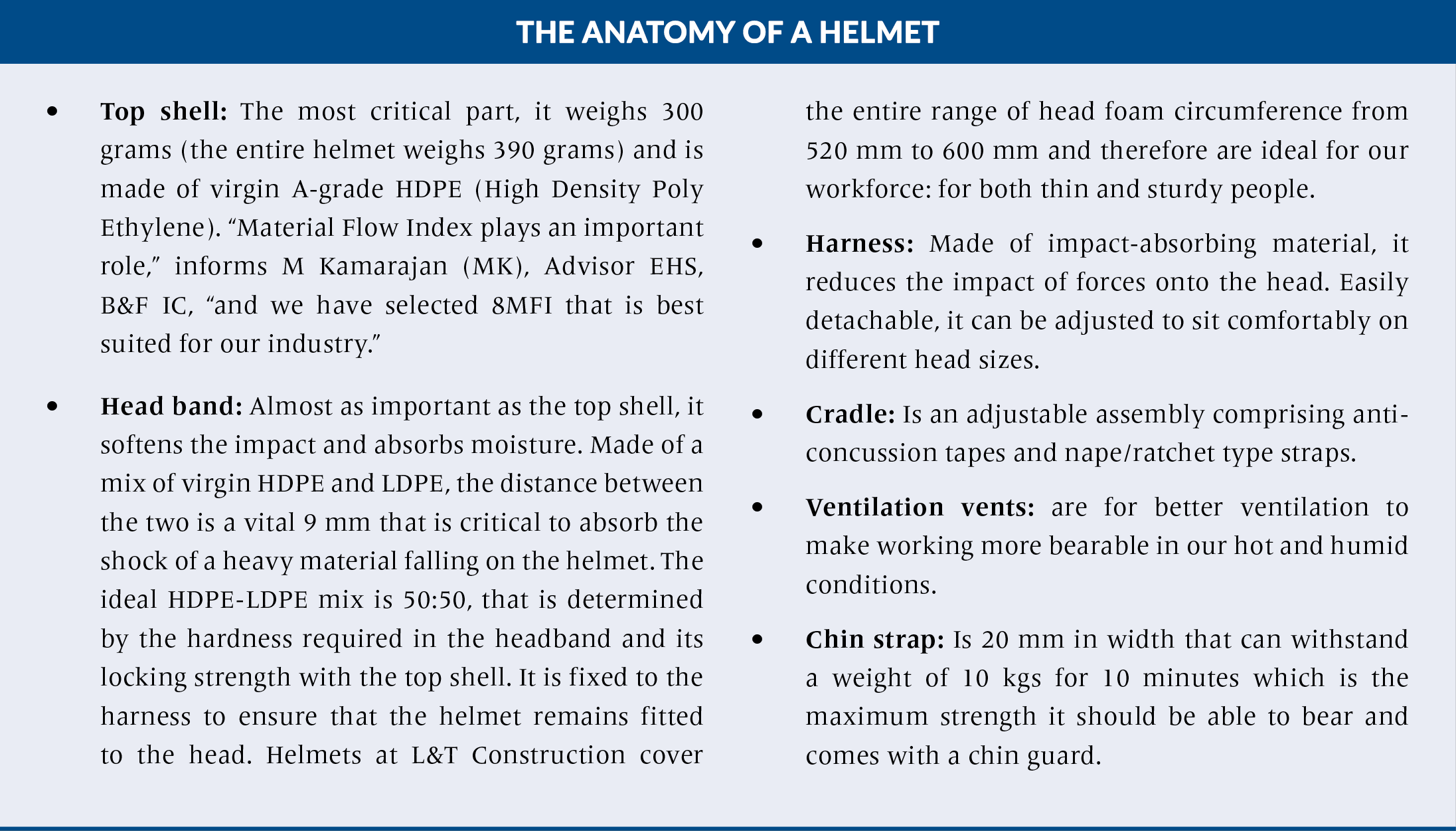

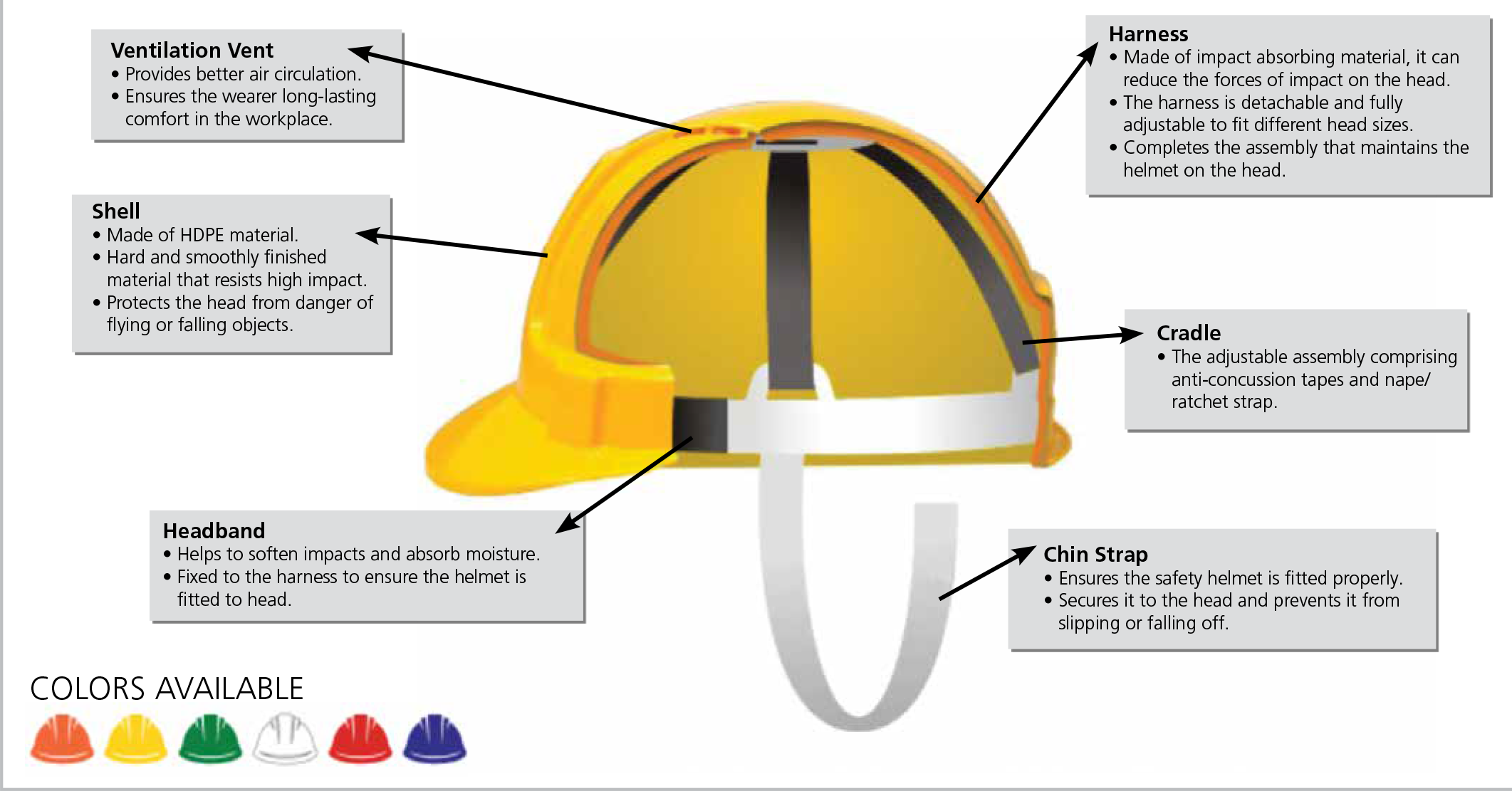

Helmets used at L&T Construction are specially designed and are of two types: Nape and Rachet types both of which are made of HDPE, with chin straps and sweat bands and ISI certified (IS 2925:1984).

Chances of survival of accident victims with helmets are significantly better. Helmets come in very useful during tunnelling activities too as a bright headgear is far more visible in the relatively dark and dust-filled work environment underground.

- Stephen Phillip Storey

Head – EHS, HCI IC

How helmets save lives

Helmets protect heads from falling objects or falling from a height or to cushion the head hitting against a hard surface to the best possible extent. “Chances of survival of accident victims with helmets are significantly better,” opines Stephen Storey, Head – EHS, Heavy Civil IC. “Helmets come in very useful during tunnelling activities too as a bright headgear is far more visible in the relatively dark and dust-filled work environment underground.” Helmets shield you from the sun’s direct UV rays, give comfort in stuffy conditions and different coloured helmets make it easy to identify personnel.

Riding the digital wave, RFID-tagged helmets are helping safety managers keep workmen safe by tracking them, preventing them from entering ‘nogo’ zones or stopping them from venturing into areas where they are either not authorised or medically unfit to enter like at heights or in a marine environment. It comes in most handy when workmen are working alone at times either at odd hours or away from the main centres of activity.

Safety demonstrations on the importance of wearing helmets

“The importance of wearing a helmet at a construction site cannot be overemphasized,” offers MK, “and, at the end of the day, if workmen are convinced that not only their lives but the livelihoods of their families depend on them staying safe and healthy, they will not mind putting on helmets,” he concludes.

The importance of wearing a helmet at a construction site cannot be over-emphasized, at the end of the day, if workmen are convinced that not only their lives but the livelihoods of their families depend on them staying safe and healthy, they will not mind putting on helmets.

- M Kamarajan

Advisor EHS, B&F IC

POWERFUL EARLY WARNING DEVICES

High voltage tester with discharge rod

Helmet mounted induction tester

PT&D IC’s Utility Power Distribution team was vexed by two hazards that their fitters frequently encountered. “One was unknowingly touching or climbing ‘live’ towers,” explains G Kartik, Project Manager, Rural Electrical Work under DDUGJY (WESCO) PK‑4, “and the other was having to face sudden power surges when stringing lines.” With the situation assuming alarming proportion, mitigation measures were an imperative and the team came up with two timely innovative solutions to overcome both these safety hazards.

One was unknowingly touching or climbing ‘live’ towers, and the other was having to face sudden power surges when stringing lines.

- G Kartik

Project Manager, Rural Electrical Work under DDUGJY (WESCO) PK‑4

Helmet Mounted Induction Tester (HMIT) is a device that is attached inside a standard helmet (IS 2925) with a small antenna sticking out that detects ‘live’ towers and alerts the fitter when he is still a few feet away. It protects the head from electrical hazards of up to 2 kV and mechanical hazards of up to 40 KN.

High Voltage Detector with Discharge Rod: Robust, lightweight and made of unbreakable ABS material with extremely good insulating properties, the High Voltage Detector with an attached discharge rod sends audio and visual alerts in the event of a sudden power surge thanks to the connection of the discharge rod cable to earthing points.

With powerful early warning devices, it has become so much safer for our fitters and our safety quotient has improved multifold.

- Jayakrishnan

EHS Coordinator

“With these innovations, it has become so much safer for our fitters and our safety quotient has improved multifold,” shares a visibly happy Cluster EHS Coordinator, Jayakrishnan.