Keeping the OHS flag flying at PT&D Middle East

“At L&T PT&D (Middle East) we live and work by the principle that we are responsible for guaranteeing a work environment that is safe for everyone, both as a BU and as individual employees,” declares Antonios Papadopoulos, Head EHS & Quality, PT&D Middle East. “With the result, health and safety is at the core of everything we do.” This philosophy extends far beyond the boundaries of project sites, forming the basis for all BU activities and setting the standard for dealings with all stakeholders — clients, consultants, suppliers, and all others.

Site Inspection

Prevention being their primary focus, the EHS team has developed robust integrated management systems with policies, procedures, and guidelines that reflect the top management’s commitment to ensure health and safety, protect the environment and, at the same time, uphold human values. The scope of systems, which are certified to ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018, includes power transmission, distribution, and renewables projects, covering operations in the three Emirates of Sharjah, Dubai, and Abu Dhabi, as well as in the Kingdom of Saudi Arabia, Qatar, Kuwait, and Bahrain.

Prevention being their primary focus, the EHS team has developed robust integrated management systems with policies, procedures, and guidelines that reflect the top management’s commitment to ensure health and safety, protect the environment and, at the same time, uphold human values.

Multiple challenges. Many solutions.

Antonios’ mandate is not easy by any stretch of imagination as the team is operating in multiple countries, with different legislative and regulatory requirements, serving a diverse client base, with varying norms and expectations. “We have developed our systems by adopting the most stringent specifications available to standardize our modus operandi across the whole of the Middle East, whilst simultaneously complying with the regulatory authorities’ demands and our clients’ expectations.”

We have developed our systems by adopting the most stringent specifications available to standardize our modus operandi across the whole of the Middle East, whilst simultaneously complying with the regulatory authorities’ demands and our clients’ expectations.

Antonios Papadopoulos

Head EHS & Quality, PT&D Middle East

Core to their EHS system is a risk management process that readily identifies all hazards and ensures suitable control measures. Task-specific risk assessments, reviewed and approved by clients and/or their consultants prior to the start of any work, are prepared for every single method statement. Specialized surveys or studies are conducted wherever required for site-specific inputs for risk assessment. In view of the dynamic nature of construction, the risk assessment process is repeated regularly throughout the duration of each activity, to counter hazards that occur due to changes in site and/or environmental conditions, as well as by new methods or materials that had not been initially accounted for.

Good systems get better when implemented well

Good systems in themselves, however, are only a means, not an end. “Effective implementation is key to achieve Mission Zero Harm which is impossible without strong management dedication,” points out Antonios. Commitment to safety starts from the BU Head, through the Country and Cluster Heads to Project Managers, permeating throughout the entire chain of command, down to the last workman. Safety Leadership Tours were launched in 2017, to increase the visibility of top management on the field and promote their commitment to OHS (Occupational Health & Safety) and environmental protection.

Effective implementation depends heavily on close collaboration between the execution and safety teams particularly since they could have, quite often, conflicting priorities. Safety issues are formally discussed at weekly meetings and informally, on an ad hoc basis, to ensure that progress and safety are maintained.

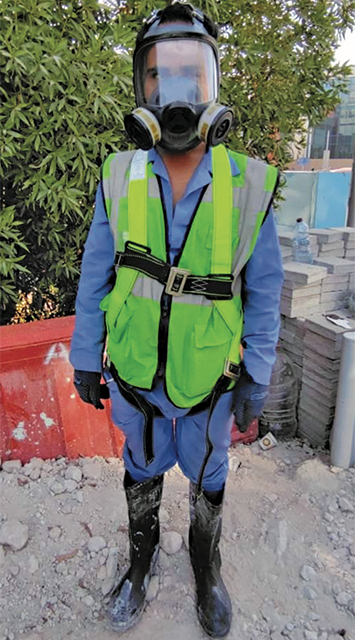

CS Entrant

Horizontal Directional Drilling (HDD) entry pit in Qatar

Issues of particular concern are, if need be, escalated to the Country or even BU level as illustrated by a recent example that Antonios elaborates. “It involved a Horizontal Directional Drilling (HDD) entry pit in Qatar, which was contaminated with hydrogen sulfide gas, at levels much higher than the short-term exposure limit (STEL) of 15 ppm.” The issue was escalated to the BU level, where suitable control measures were decided and the safety team was given ample time to procure the required respiratory protection & rescue equipment, provide third-party training to employees, prepare a site-specific method statement, do risk assessment, prepare an emergency response plan, construct a temporary structure to set up the tripod, purge and ventilate the pit.

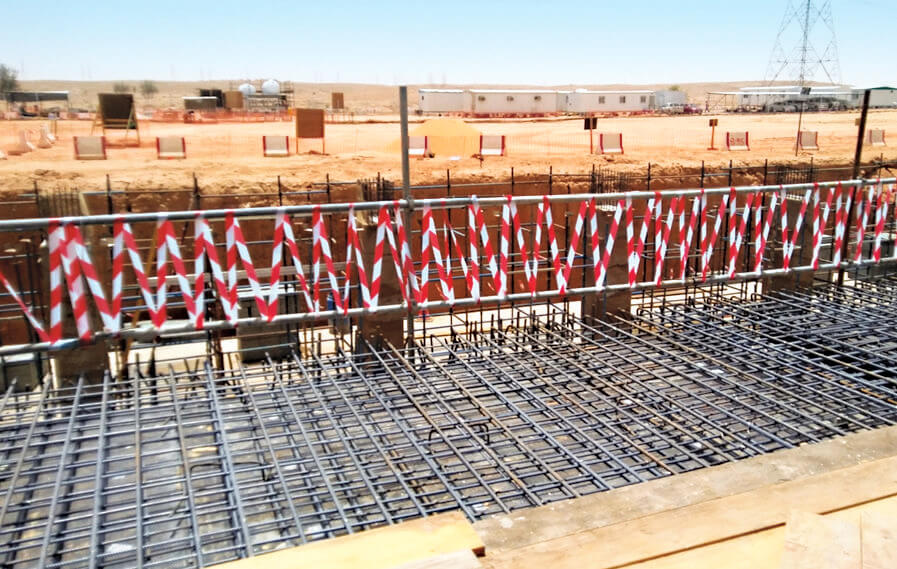

Edge Protection

Towards a positive safety culture

Maintaining and fostering a positive health and safety culture is integral to EHS performance. Employees, including subcontractor employees, are encouraged to identify and report unsafe acts and unsafe conditions, through the Safety Observation Card system, and urged to participate in developing and implementing innovative solutions to address identified issues to make their work healthier, safer, smarter, and more effective. Training is critical for this and apart from in-house training, those performing safety-critical work are given third-party certification training. At a minimum, third-party training is provided to lifting supervisors and riggers, banksmen, scaffolders and scaffolding inspectors, confined space supervisors, attendants & entrants, authorized gas testers, first aiders, fire wardens, and the like.

When conducting incident investigations, we focus on identifying and addressing root causes to prevent recurrence, avoid assigning blame, where practicable, for we believe that laying all the blame on one or more individuals is counter-productive, runs the risk of alienating the workforce and undermining the safety culture.

Antonios Papadopoulos

Head EHS & Quality, PT&D Middle East

Despite all these precautionary measures, incidents do occur that are viewed as opportunities for improvement. Antonios adds that considerable time and energy have been invested to convince employees to report all incidents, regardless of gravity, without fear of reprisal. “When conducting incident investigations, we focus on identifying and addressing root causes to prevent recurrence, avoid assigning blame, where practicable, for we believe that laying all the blame on one or more individuals is counter-productive, runs the risk of alienating the workforce and undermining the safety culture.”

Over the past few years, PT&D in the Middle East has made significant strides to create and maintain a positive safety culture and a safer workplace for employees and workmen. However, there is always room for improvement and the onus is on Antonios and his team is to remain vigilant and keep raising the safety bar to fulfil their moral obligation to the people who trustingly place their wellbeing and livelihood in their hands.