Belagavi thirsts for L&T to solve its water woes

24×7 Belagavi DB O&M Project

Presently, several households in Belagavi receive tap drinking water only 2–3 days a week for just a few hours. With WET IC’s 24×7 Design & Build and 7‑year O&M project for the Karnataka Urban Infrastructure Development & Finance Corporation (KUIDFC), the city can look forward to soon receiving a continuous supply of pressurized water. Awarded in 2020, on a Design, Build, Operate & Transfer (DBOT) mode, the project envisages cost-effective & sustainable upscaling of water supply to designated households.

Covering the entire city of Belagavi of about 100 sq. km of area, the project involves the design & construction of a 31 MLD Water Treatment Plant, 3 new pumping stations with Ground Level Clear Water Reservoirs (GLSRs), 15 Elevated Level Service Reservoirs (ELSRs), 25 km of Mild Steel (MS) pipeline, 57 km of ductile iron (DI) pipeline, 1,000 km of HDPE line network along with 85,000 House Service Connections, and associated road restoration work. These works run parallel to O&M operations of existing assets: two 100 MLD WTPs, 7 ELSRs, 5 GLSRs, and an associated pipeline network of 1,325 km.

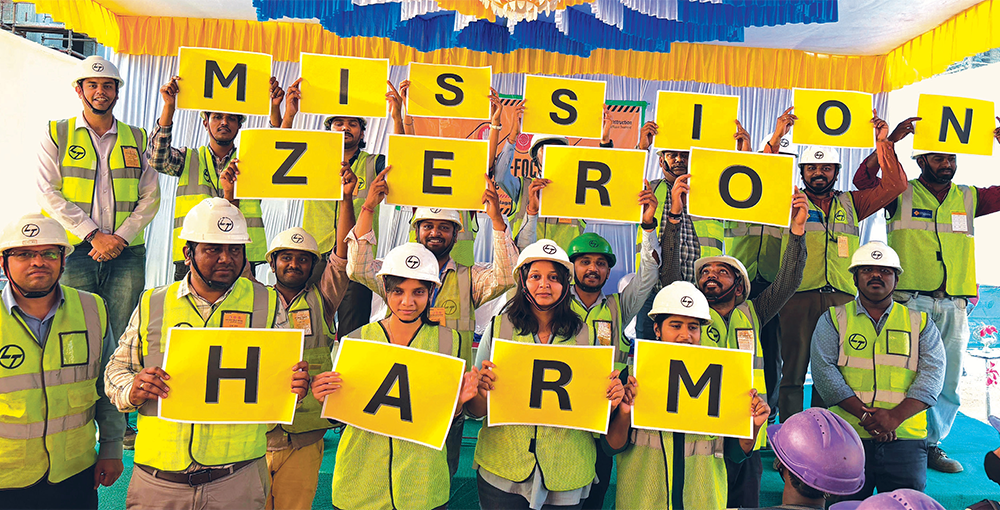

Safety is top priority

Despite executing in extremely trying conditions, Project Manager, Dheeraj K Ubhayakar, his EHS In-charges, Dinesh and Prasanna, and team have thus far clocked 8.93 million safe manhours covering both DB & O&M operations. “We have been consistently recognized for our excellence in EHS through the numerous awards and accolades we have won since inception,” shares a proud Dheeraj, “like the BSC 5‑Star Award and Sword of Honour Award for 2024, the CII-SR EHS Excellence Gold Award 2022, and the RoSPA Health and Safety Award 2023.”

![]()

We have studied and acted on various aspects that impact safety including when working in confined places or at height, during material handling, excavation or when working alone, and much more – even softer aspects like ergonomics, stress management, wellness, and well-being.

Dheeraj K Ubhayakar

Project Manager, 24x7 Belagavi DB

![]()

A key element of their EHS success story is EHS leadership and commitment, demonstrated through GEMBA audits to identify areas for improvement and implement corrective actions. PM EHS walkdowns, cross audits by construction managers, safety discussions, and mass toolbox talks during walkdowns keep EHS top of mind. “We have studied and acted on various aspects that impact safety including when working in confined places or at height, during material handling, excavation or when working alone, and much more – even softer aspects like ergonomics, stress management, wellness, and well-being,” informs Dheeraj.

5S implementation at stores

Keeping safe in confined places or at height

Critical O&M activities, like entering overhead water tanks and sumps for cleaning, are risky, and the team has implemented strict measures to ensure the safety of personnel during these confined-space activities. “Competent workers are designated; we conduct medical checks and issue confined-space skill passes, with essential resources like manlifts & communication systems,” informs Dinesh. Tripod systems, emergency rescue stretchers, multigas detectors, and LEVs are all in place, and the entire process is monitored via CCTV cameras. “Additionally, we have implemented an innovative robotic camera system to detect and rectify leaks in pipelines, which has minimized human intervention in hazardous zones,” says Dinesh, adding that the same camera was used in the Silkyara rescue operation in Uttarkashi district, Uttarakhand, to save the trapped workmen.

![]()

We have implemented an innovative robotic camera system to detect and rectify leaks in pipelines, which has minimized human intervention in hazardous zones.

Dinesh

EHS In-charge

![]()

SCBA training by an external agency

Manlifts are deployed for work-at-height activities, like accessing overhead water tanks for cleaning, conducting non-destructive tests on height structures, plastering, and painting, carried out by competent operators and workers, designated with height passes to ensure proper training. Additionally, qualified scaffolders and formwork engineers oversee all height-related activities, including the implementation of LTMS scaffolding systems and fall arrestors, with colour codes for scaffolding (green for safe areas and red for restricted or hazardous areas).

Maintaining electrical & fire safety

A comprehensive range of electrical safety measures have been implemented, like installing Earth Leak Indicators in all PDB boxes, having IP-65/IP-55 PDB boxes that protect equipment from dust and water, high-quality cable connectors and joints, electrical rescue hooks to avoid direct contact with live components, insulated rubber mats & gloves, arc suits, and an electrical goal post system that restricts access to high-voltage areas. “Our Electrical Safety Montessori Model educates workers and engineers, fostering awareness about electrical safety,” adds Prasanna.

Based on a fire risk assessment, the necessary control measures have been implemented, including the provision of fire balls, fire extinguishers, and water sprinkling systems at HDPE storage yards. Fire drills are conducted across all sites, including offices and workmen camps, and identified fire wardens in workplaces help enhance fire safety preparedness and response.

Staying safe during excavation, material handling, or when alone

Comprehensive excavation safety measures include rock fall prevention safety nets, EDRC-excavation profile drawings and shoring box implementation, road safety measures like hard barricades, traffic marshals, blinker lights, safe access & egress to the public at pipeline trench sites, caution boards in local languages, and regular training & awareness programmes for construction personnel.

Traffic marshal for road traffic management

Manual material handling can often result in musculoskeletal disorders (MSDs), fatigue, or repeated strain injuries, for which the HIRA team has conducted TILE assessments and implemented safe job designs as control measures. “Now, HSE’s MAC tool guidance is additionally followed for quantitative risk analysis, bringing excellent work adjustments and suggestions,” Dheeraj elaborates. Deploying a mobile tower crane instead of an industrial hoist has given the team greater flexibility, increased lifting capacity, improved productivity, and reduced risks.

Tank cleaning operation with tripod system, motion scout, LEV, and

full-body harness

Adequate measures are in place to ensure the safe handling of chlorine gas at site. Engineering controls include an overhead crane for lifting and lowering chlorine tonners, chlorine gas leak detectors, a neutralization system, blower system, eyewash stations, and windsocks to monitor environmental conditions. “We rigorously follow process safety measures with a HAZOP study and COSHH assessments conducted to identify potential hazards,” informs Prasanna. “Operators are thoroughly trained through our CSTI WTP Operator course, and by adhering to legal compliance standards, we have ensured a safe and controlled environment to handle chlorine gas.”

Remote or lone working, including at home or hybrid setups, is closely monitored through WhatsApp communication, CCTV surveillance, and regular training programmes. “We have expanded our safety measures to include vulnerable workers such as security staff, pump operators, drivers, and sweepers,” informs Dinesh. These groups are now part of the consultation process, risk assessments, and control measures.

EOT crane for handling of chlorine tonners

Managing stress

“We conducted an EHS Wellbeing Survey to identify ways to improve employees’ mental and emotional wellbeing,” shares Dheeraj, “and have implemented programmes based on expert advice.” Employees are urged to participate in monthly wellness programmes, Wellness Champions are identified & rewarded, and in addition to various recreational activities, the site has an ill-health monitoring system to identify causes for absenteeism. He shares an example involving valve operators traveling from remote areas who were frequently suffering from common cold and headaches due to inadequate protective gear, like helmets without visors and ear coverings. “We tracked absenteeism and addressed the issue by providing the necessary protective gear.”

Morning warmup exercise during toolbox talk

Keeping the subcontractors aligned

Based on ViewEHS data analytics, action plans are made to improve the EHS performance of subcontractors falling below 60%, which are shared with them and implemented through coaching and mentoring, workshops, conclaves, and an EHS Rewards, Memos & Reprimand system. “While we recognize EHS-compliant subcontractors, we also issue violation memos to repeat violators, and serious violators are penalized,” says Prasanna sternly. “Our efforts have borne fruit, for the subcontractors are now actively participating as EHS Ambassadors and Safety & Wellness Champions, besides significantly changing their working styles.”

![]()

While we recognize EHS-compliant subcontractors, we also issue violation memos to repeat violators, and serious violators are penalized. Our efforts have borne fruit, for the subcontractors are now actively participating as EHS Ambassadors and Safety & Wellness Champions, besides significantly changing their working styles.

Prasanna

EHS In-charge

![]()

Emergency preparedness & response

Emergency preparedness has been prioritized by identifying all applicable emergency scenarios and preparing comprehensive emergency response plans. There are control rooms within the plant, worker camp, and other critical areas, while emergency sirens ensure prompt communication during emergencies. Regular mock drills, including night drills, fire drills, and scenario-based drills, have enhanced the team’s readiness, strengthened response capabilities, and ensured a safer environment across the project.

A group risk assessment committee, including subcontractor supervisors and workmen, actively engage in hazard identification and risk assessments (HIRA) across all critical areas, including site machinery, materials, workmen habitats, fire risk assessments, routine & non-routine work activities, and office environments. HIRAs are regularly reviewed and shared with all. A dedicated EHS Committee that includes representatives from subcontractors & workers ensures active participation in the EHS process.

With such an accent on EHS, it is no surprise that Dheeraj’s team at the Belagavi project have won L&T Construction’s Safety Award 2024!