Safety is not merely a priority — it is a core value that drives the way we operate at L&T Construction. As the Head of Environment, Health, and Safety (EHS) for Health, Public Spaces, and Airports (HPA) SBG, I take immense pride in the strides we have made to embed safety into every aspect of our business processes, an integration that has not only enhanced our operational efficiency but also solidified our commitment to protecting our workforce, stakeholders, and the environment.

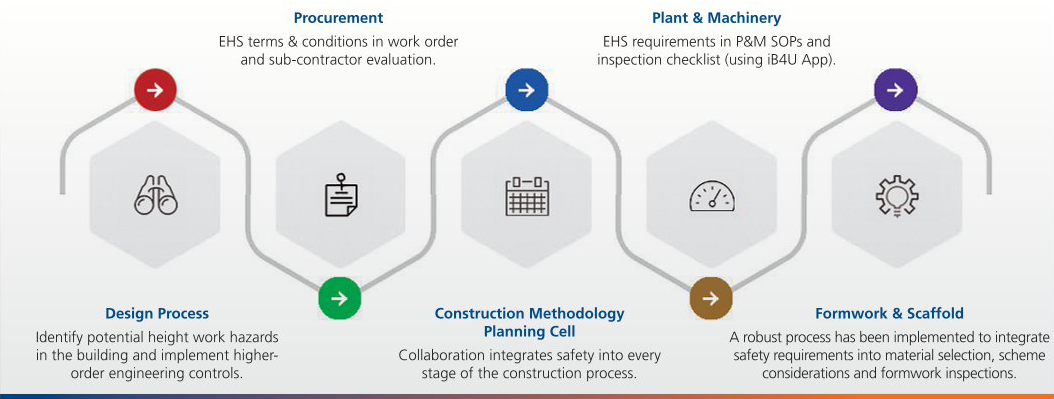

The construction industry, by its very nature, is fraught with complexities and risks. From towering structures to intricate designs, every project demands meticulous planning and execution. At L&T Construction, we have adopted a proactive approach to EHS by weaving safety considerations into our foundational processes. Let me walk you through some key areas where EHS integration has become a cornerstone of our operations:

Integrating EHS into business processes

Design — Integrating BIM for fall protection

Work at height is identified as one of the major hazards in our projects; this is further validated by our Predictive Analytics-Risk Profiling model. Building Information Modeling (BIM) has been utilized to enhance fall protection. BIM helps identify potential height work hazards in the building and provides suitable higher-order engineering controls such as safety screens, modular edge protection systems, lift and service shaft protection, etc. Through this initiative, we can manage the complete lifecycle of the fall protection system-from identification and estimation to installation, monitoring, and VR training.

Procurement – the Herculean task of managing subcontractors

In all our projects, nearly all construction activities are subcontracted. Our safety success hinges on managing these subcontractors to align with our safety culture and comply with L&T’s EHS requirements. This is meticulously achieved by integrating EHS standards right from the selection of subcontractors to the completion of their scope of work. The procurement team plays a major role by communicating EHS requirements preselection, onboarding subcontractors, and evaluating their EHS performance during project execution. This approach fosters collaboration and accountability, creating a unified front in our commitment to safety.

Construction Methodology Planning Cell — Scheme Drawings with EHS Inputs

Our construction methodology planning cell plays a crucial role in integrating EHS inputs into scheme drawings, ensuring that every aspect of the construction process is planned with safety at its core, right from conceptualization to execution.

Quality — Integrated EHS Roles and Responsibilities

Quality and safety go hand in hand. By defining and integrating EHS-related roles and responsibilities into our quality management processes, we ensure that safety is a shared responsibility across all levels of the organization. For instance, concrete pre-pour checks on safety are critically reviewed and verified jointly by quality, safety, and execution teams. This integration fosters a culture of accountability and continuous improvement.

Plant & Machinery — EHS in Inspections

The reliability of plant and machinery is pivotal to the success of any construction project. EHS requirements are embedded into the procurement, inspection and maintenance protocols for all equipment. This proactive approach minimizes downtime and enhances the safety of our operations.

Formwork & Scaffold

Formwork systems are critical to the success and safety of any construction project, often considered the bread and butter of construction-second only to concreting. A stringent process has been established to embed safety requirements in material selection, scheme considerations for access and egress, and formwork inspections. Similarly, scaffolding is treated with equal seriousness, with regular inspections aimed at improving workplace conditions. These measures provide our workforce with a secure environment to perform their tasks effectively.

We continuously invest in training and awareness programs to instill a safety-first mindset among our workforce. By empowering our teams with the knowledge and tools they need, we create an environment where safety is everyone’s responsibility.

A Culture of Safety

While processes and technologies are essential, it is the people who bring them to life. At L&T Construction, we continuously invest in training and awareness programs to instill a safety-first mindset among our workforce.

By empowering our teams with the knowledge and tools they need, we create an environment where safety is everyone’s responsibility.

EHS integration is not a one-time initiative; it is an ongoing journey that evolves with the changing dynamics of our industry. At L&T Construction, we remain steadfast in our commitment to making safety an integral part of our DNA. By embedding EHS into our business processes, we not only safeguard lives but also set benchmarks for excellence in the construction industry.

Let us continue to champion safety as a way of life and lead the way in building a safer, sustainable future.

Stay safe, stay inspired.