20 million safe manhours and counting.

Truly, an award-winning performance.

Kudankulam Nuclear Power Plant – Units 5 & 6

The team at the Kudankulam Nuclear Power Plant, Units 5 and 6 is celebrating their recognition from prestigious international and Indian institutions like the British Safety Council and RoSPA, for their exemplary approach to safety management at site. Obviously, L&T Construction’s Safety Award for 2024 is a significant addition to their rich haul of awards.

The units, currently under construction, mark the expansion of the plant and are the most technologically advanced ones, utilizing ‘third generation plus VVER reactors’ with cutting-edge safety features.

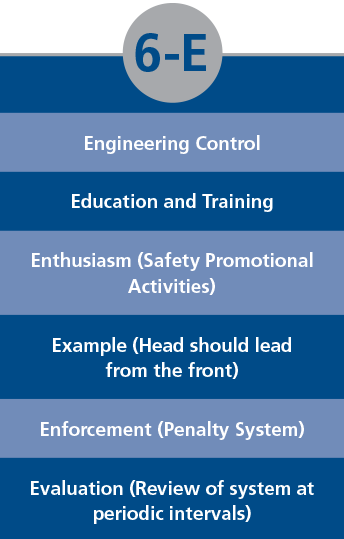

Taking the challenges of working at a nuclear power plant project in his stride, Project Head, M Kannan, proudly states, “By following stringent safety protocols we have had zero fatality in the past 4 years and clocked 20 million safe manhours till date.” To sustain a positive EHS culture, the team has implemented the 5‑i and 6‑E principles that are certainly working. “Apart from zero harm missions, we strive to proactively identify and assess workplace hazards by conducting regular safety inspections, job safety analyses, and risk assessments,” he elaborates. “Our constant focus is on accountability, empowerment and transparency that have created a culture where everyone feels comfortable to raise safety concerns without any fear of reprisal.”

![]()

By following stringent safety protocols we have had zero fatality in the past 4 years and clocked 20 million safe Manhours till date. Our constant focus is on accountability, empowerment and transparency that have created a culture where everyone feels comfortable to raise safety concerns without any fear of reprisal.

M Kannan

Project Head

![]()

Adopting a holistic approach towards EHS

A critical aspect to their EHS management is adopting a Behaviour Based Safety (BBS) approach, effectively and smartly, by emphasizing on constant awareness and real-time intervention to avoid potential hazards before they escalate. Instead of just focusing on equipment or environmental hazards, BBS emphasizes how workers behave and interact with their surroundings.

“Unsafe behaviours are often the root cause of accidents, so by correcting these behaviours, risk can be significantly reduced,” points out EHS In-charge, J Dhinesh. “Our RAKSHA i5 system combines technology with positive reinforcement by encouraging workers to follow safety protocols through rewards.” The project takes a holistic approach to address the full spectrum of employee well-being, blending physical safety with mental health support. By tying rewards and incentives to safety and well-being efforts, the team feels valued not just for their output but for their overall health as well. On offer are 24/7 on-site medical facilities, emergency response teams, and partnerships with leading hospitals for specialized care. “Regular occupational health screenings along with mental well-being programs, play a significant role in how effectively workers perform their tasks, especially in high-stake environments like nuclear power plants, where focus and clarity are essential,” nods Dhinesh.

![]()

Unsafe behaviours are often the root cause of accidents, so by correcting these behaviours, risk can be significantly reduced. Our RAKSHA i5 system combines technology with positive reinforcement by encouraging workers to follow safety protocols through rewards.

J Dhinesh

EHS In-charge

![]()

Taking the tech advantage

To ensure emergency preparedness, the team conducts drills, have rapid response teams, and set up real-time monitoring systems to ensure that everyone is ready to act swiftly and efficiently in the unlikely chance of an emergency. “Prevention is always better than cure and that is our policy too,” smiles Kannan.

BIM and VR are adding a cutting edge to their EHS endeavours with which the team is effectively managing risks and ensuring smooth operations. “BIM gives us detailed, data-rich digital models of the plant that help us identify potential hazards, plan maintenance, optimize safety protocols and detect risks before they occur,” informs Dhinesh. VR, on the other hand, by offering an immersive training experience, help workers to realistically experience risks and hazards. “We have found that VR training is particularly effective to simulate emergency situations where quick, decisive action is needed, enabling us to practice and react in a safe, controlled setting,” adds Kannan.

Daily pep talks and recognition programs like the Hi-Fi token system are other ways the team has evolved to keep safety top of mind for all. “The consistent reinforcement, along with the tangible rewards for safe behaviours, are helping us create a positive feedback loop too,” reminds Dhinesh.

Walking the talk

Safety is driven best by the leadership and that is very much the case at KKNPP 5&6. By chairing the Safety Committee Meetings and prioritizing HSE programs in weekly discussions, the site leadership ensures that safety is at the core of all operations. “Safety comes before Quality, Design, and Construction at our weekly meetings,” says Kannan with vigour, adding that, as a team, they have never held back funds to enhance safety protocols, “for we strongly believe that investing in safety can ultimately prevent greater costs down the line,” he signs off positively. That his belief is working is reflected in the project’s excellent safety record.