Sustaining the highest EHS standards for 100 months and counting …

WDFC EMP 16

Automated OHE wiring installation at the yard

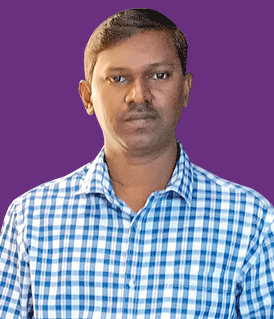

Only the cream of the crop wins the annual L&T Construction Safety Award. The WDFC (Western Dedicated Freight Corridor) EMP 16 Project has won it twice! To have traversed over 100 months of execution with Zero LTI is certainly a standout EHS performance that Project Director Samir Kumar Gupta, his SHE Director Sandeep Shirsat, and the entire project team have much to celebrate about. “Railway OHE (Overhead Electrification) construction projects are complex and challenging, involving heavy machinery, intricate engineering, and a workforce operating not only across a wide expanse but also in demanding environments, like, in our case, beside a ‘live’ railway corridor that sees 180 trains a day, with a train passing every 10 minutes,” explains Samir, “but we have crossed 8 years of execution without a single LTI,” he flashes a satisfied smile.

![]()

Railway OHE (Overhead Electrification) construction projects are complex and challenging, operating beside a ‘live’ railway corridor that sees 180 trains a day, with a train passing every 10 minutes but we have crossed 8 years of execution without a single LTI.

Samir Kumar Gupta

Project Director

![]()

The EMP 16 Package involves the electrification of 2×25 kV High Rise OHE (932 TKM), including a Gas Insulated Traction Substation, 6 Air Insulated Traction Substations, 40 Switching Stations, and SCADA system between JNPT and Makarpura on an EPC basis for DFCCIL, further involving installing high-rise overhead catenary systems, high-voltage substations, and auxiliary equipment, all aimed to enhance operational efficiency, reduce carbon emissions, and improve reliability.

![]()

OHE projects are inherently highrisk, demanding rigorous safety planning and execution, and that we have already clocked 8.8 safe million manhours reflects our commitment that every worker, contractor, and stakeholder should return home safe and sound each day.

Sandeep Shirsat

SHE Director

![]()

“The success of any infrastructure project is measured not just by its technical and operational achievements but by its EHS accomplishments too,” notes Sandeep, sounding like the true-blood EHS professional he is. “OHE projects are inherently high-risk, demanding rigorous safety planning and execution, and that we have already clocked 8.8 safe million manhours reflects our commitment that every worker, contractor, and stakeholder should return home safe and sound each day,” bringing to play his rich experience of over 27 years including tenures in four countries across continents, which adds to Samir’s 28+ years with L&T.

Revelling in the challenges

Working in the EHS field for the past 18 across the country, with 6+ years with DFCCIL as the client, has shaped Pratyush Bagchi, Manager – EHS, into a specialist on this terrain. “It has been challenging yet enjoyable to work on a DFCC project with a major portion of railway track laid in parallel to the busiest Indian Railway route,” he notes proudly. “Comprehensive training using VR modules and live demonstrations help our team understand the importance of safety and the emergency measures required to deal with any kind of adverse situation.”

Pratyush Bagchi

Manager – EHS

Diligent measures keep Safety on the rail

Since their complex operations involve working at height, managing high-voltage systems, and coordinating across multiple teams, the team has embedded safety into every phase of the project – from planning and design to execution and commissioning. Over 8,500 hours of tailored safety training sessions that include VR modules, covering topics like working at heights, electrical safety, & emergency response and specialized workshops & simulations, have helped create a workforce possessing the right knowledge and skills critical to ensure safety. Further, measures like high-voltage detectors and helmet-mounted sensors have significantly reduced human exposure to high-risk areas, apart from using window and rescue kits for conductor jumper cable works at heights of 12–15 m in all substations and cradle platforms made from site scrap for OHE cantilever erection work to guard the workers from ergonomic hazards while working at heights.

Traction Substation

Digital tools like SHEILD have made life easier for people like Senior EHS Manager A Vijayaraman, for whom identifying unsafe acts/unsafe conditions to ensure timely closure of observations is so much easier. A key contributor to the project receiving ISO 45001 & 14001 certifications, he says that their team constantly works in close vicinity to 25 kV current. “A disciplined approach and consistent training of the workmen and staff are reasons for our error-free work, in compliance with all our safety procedures,” he says purposefully.

![]()

A disciplined approach and consistent training of the workmen and staff are reasons for our error-free work, in compliance with all our safety procedures.

A Vijayaraman

Senior EHS Manager

![]()

Prevention is infinitely better than cure

Actively involved in developing safe work procedures, Manager – EHS Pratyush Bagchi is a Chief Accident Prevention Officer (CAPO) at site, whose work is cut out with the team executing parallel to one of the busiest routes of the Indian Railways, the Ahmedabad–Mumbai sector. Possessing the skill to look at things at a micro level, he describes a normal day at work: “Our day starts with a toolbox talk to understand the task at hand, related hazards, and mitigation measures required, after which we start our daily activities, ever vigilant for any issues that might crop up during execution.”

The ‘go-to’ man

The team turns to Kedarnath Barik, Assistant Manager – EHS, for support with anything safety-related. “I keep training the workers on a regular basis so that they are aware of correct grounding and discharging procedures,” he says, adding that his team is his extended family, and he binds the team together to deliver the results they are known for. Kedarnath’s happy family at home includes his wife, a homemaker, and their two small angels.

Kedarnath Barik

Assistant Manager – EHS

Another seasoned campaigner is Assistant Manager – EHS Kedarnath Barik, who with his decade-long service with L&T is the ‘go-to’ guy in any situation to resolve safety-related issues. Instrumental in implementing the ‘Power Block’ procedure and ensuring compliance to LOTO systems, Kedarnath fine-tunes safe work procedures for the Traffic and Power Blocks. “I ensure that every worker wears a helmet-mounted detector and uses the high-voltage detector before they venture into critical zones.”

Unwavering commitment to Safety

Assistant Manager – EHS, Raushan Kumar’s journey with L&T began in 2019 as a PGET, and since then, he has served on the WDFC EMP 16 Project to make an impact with his meticulous focus on safety and innovative practices. Raushan’s work went a long way in the project winning several prestigious awards. “I believe that prioritizing safety not only protects lives but also enhances operational efficiency and fosters stakeholder confidence.”

Hailing from Begusarai, Bihar, Raushan enjoys travelling and reading history books. He is happily married to Shumanchi Singh, who has been his support throughout his career. Reflecting on his journey, he says, “I am proud to contribute to L&T’s legacy as a ‘Great Place to Work’!”

Raushan Kumar

Assistant Manager – EHS

Setting benchmarks for safety in railway electrification

Recognition from industry peers and stakeholders for the EMP 16 team’s EHS excellence is reflected in the several national and international awards they have won from reputed institutions – two RoSPA Gold Medals (2023 & 2024, awarded for achieving the RoSPA Gold for 5+ years in a row), four BSC ISA Awards (2020–23), the NSC Prashansa Patra (2021), and the FICCI Safety Award (2023). Additionally, there have been many internal awards as well: three LIFE Awards (2022–24, including a Platinum Award in 2023) and the L&T Construction Safety Award for 2023.

The EHS success of EMP 16 has reinforced that safety is not just a priority but a value integral to every stage of execution, with collaboration, technology adoption, and continuous learning at its core. “We have kept learning from the many near misses and accidents in our own backyard as well as those that have occurred at other similar projects, which has been cascaded to all at sites with great results,” says Sandeep seriously.

For Samir, on the other hand, their achievements reaffirm that safety is not an ancillary objective but a core driver of success in railway infrastructure development. “By adopting a holistic approach to safety, even our future projects at RBG can continue to push the boundaries of innovation and sustainability while safeguarding the most valuable asset – that is, human life,” he rounds off with gravitas. “Moreover, creating a safety-first culture has fostered trust, boosted workforce morale, and ultimately enhanced overall productivity.”