At his Surya WSS Project, Akhilesh Singh finds himself having to juggle a wide variety of variables involving stakeholders and processes. “Ours is a complex project,” he nods vigorously, “and the success of such projects depends on several key factors, including proactive planning and the ability to respond effectively to emerging circumstances.”

His words of wisdom are borne out as much of the project area is in a hard rock forest with the ROW running parallel to the National Highway. “Procuring clearances from regulatory bodies like the Forest Department and PESO sometimes take ages. Often, we are forced to slow down or even stop construction due to heavy rains as working in wet conditions increases the risk of accidents and injuries to workers, all of which cause delays, adversely impacting our deadlines,” this time he shakes his head. Therefore, the team assigned a dedicated team to handle all regulatory-related issues while a flexible schedule factored in possible weather-related delays.

The project involves laying an 82-km pipeline and executing two MBRs, both in hilly terrains, and as Akhilesh says, “It was my first experience of moving materials and executing MBRs in hilly areas, but I accepted the challenge and completed the task,” he smiles gamely. Since the motorized screen to filter the excavated soil and rock proved unproductive, the team shifted to a mechanical sieving bucket, and by using mobile formwork for the MBR wall construction, they have reduced manhours and increased work productivity.

“Resource planning involves identifying the necessary tools, materials, human resources, and budgets required,” Akhilesh points out insightfully, “and proper resource allocation prevents shortages or overages, which act as catalysts to hassle-free execution and unhindered progress at site.” Although the team must negotiate 3 river crossings and build 2 micro tunnels, 2 MBRs, and a railway and highway crossing each, their efficient resource planning and management in execution has won them the customer’s appreciation.

Akhilesh believes that positive reinforcement and cooperation contribute to a healthy work environment, increased morale and acknowledges the active role played by his seniors and team members. “They provide valuable insight, advice, and guidance for us to meet challenges, make informed decisions, and learn from our mistakes,” he states gratefully.

A native of Kushinagar, Uttar Pradesh, Akhilesh is married to Vijay Laxmi Singh, a homemaker, and they are blessed with two children, Aradhaya and Lokesh. He unwinds on weekends watching cricket and movies and travelling.

“L&T emphasizes the significance of a flexible work environment, trust in employees’ capabilities and a culture of support, all of which result in motivation, more engagement, and better results,” he concludes on a high.

Even as young Ashutosh Shukla has been gradually finding his feet at his first project with L&T at WET IC’s Surya Water Supply Scheme Project, what has brightened his tenure has been the constant appreciation from the organization that he and the project team have received for their outstanding contribution to the project. “To be honest, this appreciation has filled me with confidence to take up the opportunity to lead the planning department of this prestigious project,” he says with all the josh of a charged newcomer that translates into awe and respect for the company he works for. “L&T’s vision and focus on the safety of people (Mission Zero Harm) and the environment make me proud to be a part of it.”

His project did not start off on the right foot, with execution held up due to a delay in handing over encumbrance-free workfront, and although providing access to site is in the client’s scope, it is important to properly notify the reasons for delays under various contractual provisions to be correctly compensated for the required time and cost. “To address this issue, we ensured timely notification and certification of all delays from the client under the relevant contractual provisions,” informs Ashutosh and adds triumphantly, “We received cost and time compensation for the contract period lost due to various reasons not attributable to L&T.”

Ashutosh flags off the use of hollow core slabs instead of cast in situ for both the master balancing reservoirs and the clear water reservoir as a smart ploy to reduce execution time and increase productivity. “Other reasons for our success have been the application of value engineering, implementation of advanced construction methodologies, precise vendor identification, fulfilment of contractual requirements (customer delight), quick client approvals on designs and drawings, methodical production, delivery and erection at site, in which I have been playing a key role,” he says, with a beaming face, “and I am delighted to have been part of the team that achieved a significant milestone of completing 4.6 km water tunnel in a single drive of TBM, the longest tunnel executed by L&T with a TBM”.

“Digitalization,” he nods, “has quickened processes, saving time and costs,” adding that progress monitoring through E-Pragati and GIS have made a significant impact.

His 6-year tenure at the project has been fulfilling thanks to his seniors at the site constantly pushing, motivating, and guiding him. “I truly believe that I have been able to add various skill sets to my personality,” he says with loads of self-assurance.

A GET from the batch of 2017, Ashutosh hails from Lucknow, Uttar Pradesh, and is married to Vaishali, a teacher by profession. When not building defining water infrastructure, he follows his other passion, singing.

A weekend football player, who loves to travel whenever possible and capture memories through his camera lens, Surajit Mondal breaks into a smile when he talks about the projects he has been a part of at L&T, crediting his seniors and team members for his growth. “Thanks to them I have learnt appropriate decision making, how to develop myself as a technical professional capable of independently heading a department,” he says with surging self-confidence.

After being a Cluster Co-ordinator in a business development role for 4 years, Surajit moved to designing and building STPs of installed capacities of 18 MLD and 6 MLD that involved building a new underground sewerage network of 247 km, constructing 12 pumping stations and all other allied work, in addition to 10 years’ O&M. “There I learnt the nuances of planning and thereafter understood the demands of execution at my next STP project, where we built a new sewerage network of 172 km and constructed 4 pumping stations,” he shares.

Swiftly handled in 9 months, Surajit says, “apart from execution, that project taught me how to efficiently mobilize resources as per the project requirements for timely completion. I had a rush of adrenalin during the commissioning of the intake well and the WTP,” he adds with a broad smile.

A native of Kolkata and married to Arijita Roy, who is a homemaker, Surajit cherishes the day he bought his first car. An ardent believer in the value and ethics of L&T, Surajit continues to develop himself with passion and commitment.

Fortified with this learning, Surajit began work at his present assignment, the Surya WSS Project, where he is impressed that 90% of the project’s assets are IoT enabled. “Fuel sensors have been installed on more than 50% of the assets,” he points out, “diesel dispensing is being monitored by an RFID-based system, the first of its kind, and diesel distribution is through an automated FDMS system.” While e-Pragathi tracks project progress, real-time asset monitoring is through a web portal and a mobile application called SPOTRACK, with all key stakeholders at the project and cluster having access to it.

“My primary responsibility is timely resource mobilization as per the project requirements, which go a long way to complete the work on time,” he says with a sense of purpose. “Resource mobilization at the critical location of the MBR was challenging, but I was able to deploy agencies through my previous project links.”

Sidharth Ray, from Odisha, loves challenges, which is evident in the projects he has worked on since joining L&T as a DET in 2011. A collaborative and self-motivated individual, he pushes himself to deliver his best. A successful debut with the erstwhile MMH SBG at the Tata Steel KPO Project that involved the structural and equipment erection of a slag granulation plant of Blast Furnace 1 won him another challenging project as a site engineer in WET IC in 2016, at the Surya WSS Project involving 82 km of pipelaying.

“This has been a huge task,” he says, “having to work on a challenging rocky terrain, in wild forests, having to negotiate the heavy monsoon and face the delays in procuring permissions from multiple stakeholders like the forest authorities and PESO.” The ROW clearance had to be taken too as the team had 3 river crossings during execution. “Our plan of action to overcome these challenges was to create a flexible project schedule, put in place the right resources and effective tools and have a strong planning and execution team,” he says purposefully. The result has been better productivity and enhanced efficiency. A dedicated team handled all the required regulations apart from staying alert for any changes in the rules and statutory requirements.

The site was not easy to work at due to the hard rock stratum, and additionally, they were contractually obliged to provide 300 m of soft bedding and backfilling beneath and above the pipelines, which they addressed by creating a motorized sieving bucket that replaced the conventional mechanical screens used to generate the sieved material from the excavated soil. “We were more productive with less manpower,” winks Sidharth. “But seriously, technology and digitalization have helped to quicken execution,” he adds.

Continuous learning from his seniors and his teams has helped him in quality execution. He appreciates the freedom the organization provides and strongly quotes it as one of the reasons why he loves pushing beyond his limits. He is proud of the BSC Five Star Rating his site has received for their EHS implementation and the use of 5D BIM for structures.

On his personal side, Priyambada is Sidharth’s better half, and his most cherished moment in life was when his son Rudransh was born. He picks up his endless quest for challenges from his love for chess and books.

A true achiever, Sidharth braves the rough and tough to go beyond his limits. Kudos to his spirit!

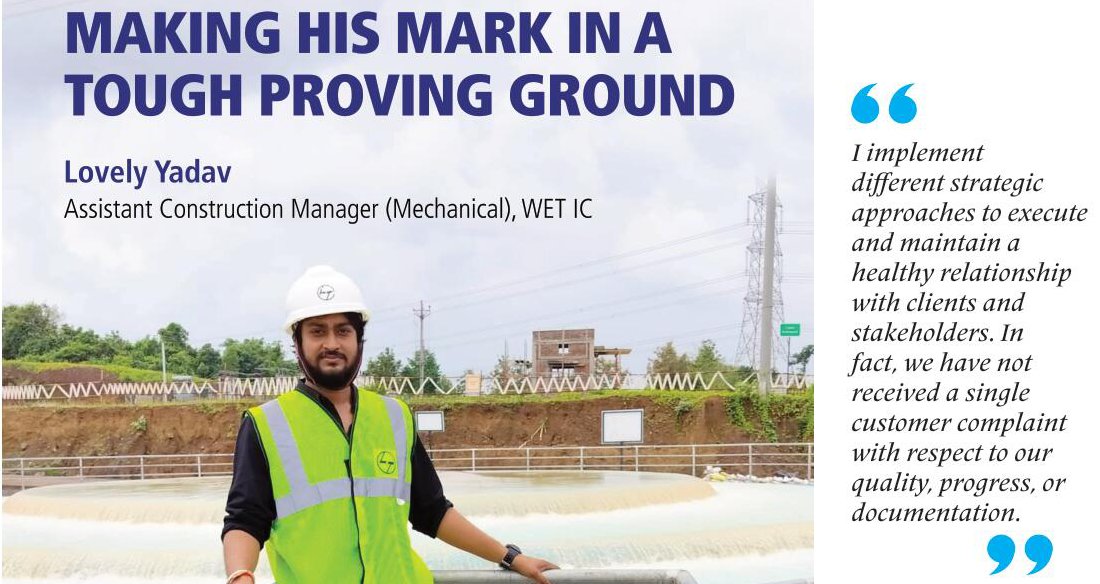

His life’s most memorable moment was when his name appeared in L&T’s list of selected candidates from NIT Agartala. “It was like a dream come true,” exclaims Lovely Yadav, “and what impresses me most about L&T is that employees are able to deliver their best because of the freedom they enjoy.” A GET from the 2017 batch, his 5 years at the Surya WSS, his first project, were interrupted for 8 months when he was deputed to the IWSGB (Introduction of Water Supply to Greater Berhampur) Project in Odisha. Returning at a critical stage with pipe laying lagging, Lovely pitched in by contributing significantly to speeding up pipe laying.

Like at most projects, the team has had to face and overcome several challenges. Land acquisition and removal of encroachments were the biggest thorns in their side, apart from procuring the necessary permits, dealing with a hard rock stratum, and managing controlled blasting next to the National Highway. “We have been laying pipes in extremely difficult terrains like hillocks and ponds, having to manage as many as three major river crossings and, perhaps, the most difficult of all, dealing with local people, landowners and local politicians,” he says with a long face. “But, despite all these challenges, we have been succeeding in very good time,” he says, his face beaming.

That Lovely has been enjoying himself is evident from the list of initiatives that he has been a part of, including implementing 5D BIM, encouraging a culture of continuous improvement, and adopting lean construction principles that involve careful planning, just-in-time deliveries of materials, and optimizing workflows to reduce delays and cost overruns. “We have been successfully mobilizing both men and machinery in time thanks to our proper resource management,” he says, flagging off some of his personal triumphs. “I help develop my subordinates, resolve technical issues on time with minimum compliances, implement different strategic approaches to execute and maintain a healthy relationship with clients and stakeholders. In fact, we have not received a single customer complaint with respect to our quality, progress, or documentation,” he declares proudly.

While he has learnt a lot on the job, he has learnt equally from his “experienced, technically sound and supportive seniors,” he acknowledges, especially his Project Director, Colin Nonis. “Their expertise, best practices, and lessons contribute hugely to the overall success of the team and project. By bringing diverse perspectives, they challenge the team to explore different options and help to create an enabling culture for all-round growth.” He adds that his team members are all very supportive and always ready to assist.

Hailing from Patna, Bihar, Lovely is yet to find a lovely partner, so for the time being, he enjoys playing badminton, reading, and exploring technical aspects over weekends.

DRIVEN TO FIND INNOVATIVE SOLUTIONS

S Muralidharan is impressed by L&T’s commitment to innovation and technological advancements. “L&T pushes boundaries and embraces new ideas in various sectors that have presented me with exciting opportunities to contribute to cutting-edge projects and solutions,” he says, full of awe for the Company he joined as a GET in 2017. Interestingly, his entire tenure till date has been at the Surya WSS Project, where he has been driving quality.

“Through strategic digitalization, we have achieved remarkable progress,” he says proudly, “like introducing digital requests for inspection, automating welder number generation, and training reminders.” He flags off the implementation of the FCAW welding process in the circumferential joints as a major initiative that “optimized processes, ensured timely inspections, efficient documentation, and prepared a skilled workforce that are all pivotal to our project’s successful and efficient delivery.” In fact, the process is now being deployed at various sites of WET IC to increase the productivity of the pipe-laying process.

Muralidharan recalls several noteworthy instances during the implementation process, like a major technical obstacle that threatened to impede progress but was resolved by successfully rejuvenating the TBM cutterhead for the second drive at the Tungareshwar site. Another timely intervention was the nondestructive testing of girth joints of the large-diameter pipeline at various locations by a third-party agency, for which the team established an in-house testing facility with a team of proficient individuals, incorporating cutting-edge equipment. “Our strategy alleviated the constraint, improved the level of quality control, made us self-reliant and reduced costs,” points out Muralidharan.

Digitalization has, he agrees, driven project progress, revolutionized data management and analysis, improved collaboration and enhanced the site’s productivity, precision, and safety standards.

“In essence, my Project Director’s unwavering support and the camaraderie among my seniors and team members have played a crucial role in my success,” says Muralidharan passionately. “Their collective knowledge, experience, and willingness to collaborate have truly made a difference and enabled me to achieve outcomes that I could not have accomplished alone.”

Muralidharan is a native of Nalladisenai, a village in Tamil Nadu’s Tiruvannamalai district. He is still single and loves to read and explore innovative technologies when free. “My most memorable moments include instances of overcoming challenges and making predictions that help me and project outcomes, and these are moments that have shaped my identity and continue to inspire me,” he signs off on a positive note.

A true tech buff, Jitendra loves to play around with mechanical components like engines, gear boxes and hydraulic pumps, a hobby that is standing him in good stead as he works on challenging projects. His first with L&T was the WSP in Nashik that proved his learning ground to understand project implementation and site execution. Presently, at the Surya WSS Project, though exposed to various other aspects of execution, what he considers defining are the erection of high-capacity gantry cranes and the transportation, lowering, assembly and commissioning of the tunnel boring machine and locomotives, which he describes as a “a life changing project for me!”

“The erection of such high-capacity gantry cranes was new as we had never erected such equipment earlier,” points out Jitendra, “so we created a clear methodology, SOPs and HIRA involving all the team members to successfully carry out the erections safely and without incident.” Working alongside the NH48 has its own set of challenges, like the lack of space to assemble and dismantle the P&M assets, forcing the team to identify specific locations for it. Tunnelling, too, was new for WET IC, and they developed an inhouse mechanical team to refurbish the locomotives. His passion turned into work when the team developed an in-house electrical & mechanical workshop for engine overhauling and repairing.

Digitalization is at the fore with IoT and fuel sensors implemented on all the P&M assets. “Monitoring operations have become so much easier since our project is spread across the 80 km highway,” notes Jitendra. “Technology has reduced our dependence on physical monitoring and, at the same time, increased efficiency and productivity,” he says happily. “I implemented IoT devices in the Nashik WSP and achieved 100% digitalization, as is the case here too.” He adds that the Surya WSS is the first WET Project to implement an RFID-based fuel dispensing system that has saves both manhours and refuelling time for assets.

He proudly acknowledges that his seniors and colleagues have played a key role in his growth, teaching him not just technical skills but softer skills as well. His significant learnings of decisionmaking, risk management, negotiation skills, etc. are from Surya WSS, which he considers has been his one-stop shop to learn, plan, and execute.

Hailing from Chikhali, Tirora in Maharashtra, Jitendra is still single and pursues hobbies like trekking and music, whenever possible.

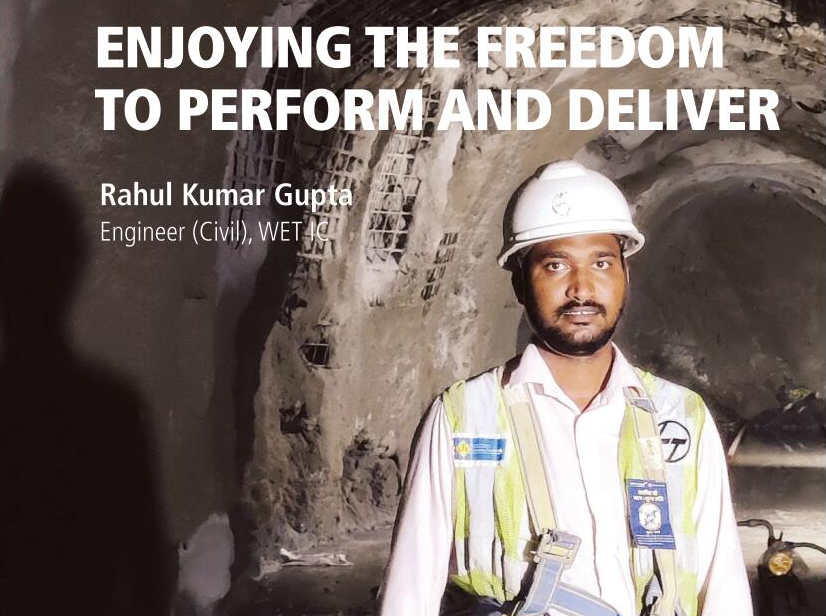

Working on his first project with L&T, the Surya Water Supply Scheme, since joining the Company as a DET in 2017, Rahul Kumar Gupta is enjoying the freedom to perform and deliver one’s best. “I am extremely motivated,” he says with complete conviction, “and when we work it is with the comforting feeling that we are protected if, unfortunately, things go beyond the plan.” This sense of assurance, according to Rahul, is a great positive when working on a project like theirs, in which so many things are beyond their control.

The monsoon significantly impacts construction schedules and productivity, and the team’s response has been to have a flexible schedule that accounts for potential weather-related delays. “Additionally, we implement several measures to protect the construction site and materials from adverse weather conditions,” highlights Rahul. A dedicated team member was assigned to handle regulatory compliances and procure permits like forest clearances that are time-consuming and often cause delays at the start of a project, adversely impacting progress and delivery. “It was also critical to stay informed of any changes in the regulations that could impact the project,” points out Rahul, insightfully.

While ROW-related issues have remained a headache throughout the project, a couple of other challenges the team faced were rock blasting along the National Highway and ensuring adherence to environmental regulations and sustainable practices that added a layer of complexity to project planning and execution. “As a major part of the pipeline alignment consisted of a hard rock stratum, we had a contractual obligation to protect the pipe with soil murrum,” points out Rahul, who is pleased with their innovation of introducing a sieving bucket attached to the excavator that speeded up progress.

About his own modus operandi, Rahul mentions having a detailed project plan with a clear scope of work, realistic timelines, and a well-defined budget. “We can anticipate potential challenges and be flexible enough to create contingency plans,” he notes. “It was just as important to promote collaboration and teamwork among the different parties to encourage problem-solving and have decision-making discussions to address challenges collectively.” Rahul is particularly happy with the site’s 5-star rating from BSC for their exemplary EHS implementation.

“I am immensely privileged to have seniors with loads of experience to support and guide me and team members always ready to assist whenever needed,” he says, adding that his best moment was becoming a part of L&T.

From Ghazipur, Uttar Pradesh, Rahul is still single and loves to play cricket when he finds the time for it.