UNITED WE STAND!

Uday Chakraborthy

Construction Manager (Mechanical), M&M SBG

A good, positive working environment and the unity amongst team members are what Uday Chakraborthy holds dear at L&T. Presently, he is at the VL Expansion Project at Lanjigarh, Odisha. “No, this is not my first project with L&T,” he shakes his head, mentioning that he has previously worked at a handful of other L&T projects, starting with the Bhushan Angul Sinter Plant 204 m2*2, the TATA Steel Kalinga Nagar 1.5 MTPA plant, EGA Abu Dhabi 2 MTPA Plant, the 3 MTPA RSP, and the UAIL Tikri 0.5 MTPA plant before joining the VL Project, where his proudest achievement has been to complete 2 lakh IM hydrotests in a month.

Working at such a remote location has it own set of challenges and the Lanjgarh Project is also unique in the set of difficult questions it poses to executing teams. Some of Uday’s primary tasks have been to dismantle old pipes at the old pipe rack, continuously following up with both the Client, Vedanta Limited, and his own team. What did he find most difficult? “Pipe erection and alignment at LFR below the platform and PPT tank top pipe erection,” he answers unhesitatingly.

Technology, automation and digital solutions are driving efficiency at the site, and Uday mentions daily monitoring of DPR and SOSC as two major digital interventions that are helping the project team hugely. “The CMPC prepares the scheme for the blind lifts, heavy lifts and critical lifts and we execute accordingly,” he smiles, “and thus far we have performed exceedingly well.”

Uday is proud of his achievements at some of his previous assignments, mentioning the 8,500 IM pipe erection completed in a day at the UAIL Plant at Tikri and a 34 MT single-piece duct erected at the Bhushan Sinter Plant. “I owe my success to my seniors for their leadership, support, guidance, ideas and for helping me with timely resources to complete my various tasks in time and to the satisfaction of all,” his says, visibly grateful.

A native of Asansol in West Bengal, Uday is married to Chaitali, a homemaker, and his life’s most precious moment has been the birth of his son, Soumalya. When he finds the time for it, he loves playing cricket.

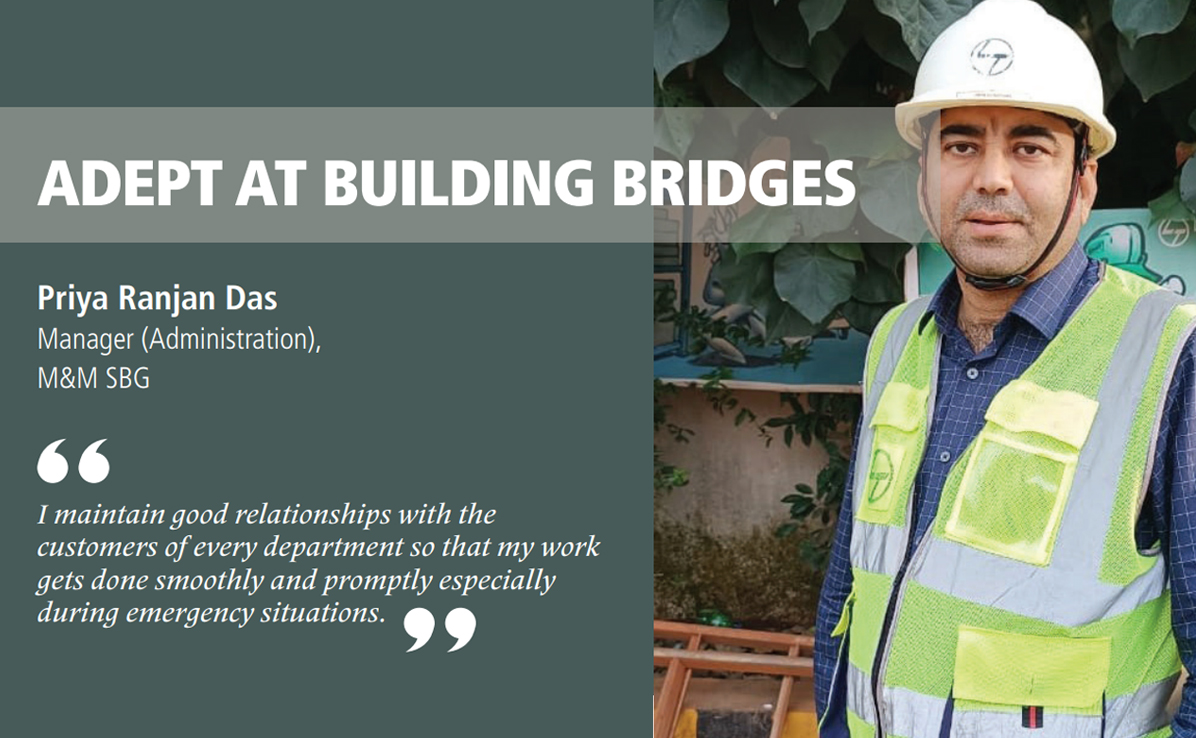

From his years of experience and already at his 6th project with L&T at the Vedanta Alumina Refinery site at Lanjigarh, Priya Ranjan Das has discovered that a harmonious environment and building human bridges are key to dealing effectively with stakeholders. “I maintain good relationships with the customers of every department so that my work gets done smoothly and promptly, especially during emergency situations,” attributing reasons for his success as an IR professional.

Looking back at his career, Das shares, “I have implemented several special and unique initiatives at every project that I have worked at and contributed towards delivery and improving labour management, establishing committees of union representatives and management personnel to collaboratively address specific issues, which fosters a more cooperative and understanding work environment, reducing the likelihood of disputes and strikes.” He agrees that managing workmen relations and addressing grievances effectively are critical to maintaining a positive work culture by promoting open-door policies and two-way communication.

He recalls a defining moment when he successfully mediated for a high-stakes labour dispute that had the potential to disrupt a major project. “By facilitating constructive dialogue and finding a common I maintain good relationships with the customers of every department so that my work gets done smoothly and promptly especially during emergency situations. ADEPT AT BUILDING BRIDGES Priya Ranjan Das Manager (Administration), M&M SBG ground, we resolved the issue amicably, maintaining project timelines and preserving the relationship between the workforce and management,” he shares with a broad smile. Adapting labour strategies to changing market conditions and economic challenges are an ongoing process that includes adjusting labour schedules and optimizing workforce planning.

Recognizing the importance of employee well-being, Das has introduced comprehensive wellness and health programmes at multiple sites such as stress management workshops, providing access to counselling services, arranging for annual medical checkups to improve employee morale and overall health, resulting in reduced absenteeism and increased productivity. “I launched a safety awareness campaign that included regular safety drills, training sessions, and recognition programmes for safe behaviour that significantly reduced workplace accidents and injuries and improved the overall safety culture,” he says. “After the closure of each site, I ensure completion of all statutory compliances and settle all legal dues in accordance with legal requirements.”

For a role that demands collaboration, Das is thankful for his seniors’ and team members’ support and guidance, and mentorship from senior leaders like Project Accountant P. K. Das and Project Manager Sanjay Saha. “Their insights have helped me navigate complex labour issues and make informed decisions,” he mentions.

Hailing from Cuttack, Odisha, Das’s life partner is Jayashree, a homemaker, and they are blessed with a son, Swastik Suman Das, whose birth was his most memorable personal moment. Playing badminton is what he loves when free.

He feels fortunate for the opportunity to execute various projects with L&T, but Barkat Hussain agrees that his present assignment at Vedanta’s Alumina Refinery Expansion Project is his most challenging and unique. “It is a once in a lifetime opportunity to complete a project that had been abruptly abandoned nearly 12 years ago,” he conveys, “but unlike in any fresh project where work fronts are generated sequentially, here we had multiple work fronts available for execution simultaneously, making planning and execution extremely tough.” He pauses in thought for a moment and continues, “We have had to seek new and innovative methods to execute safely and in very little time with good quality,” and Barkat is relieved that they have completed some risky work safely, maintaining productivity.

He is particularly happy about two tasks that the team has performed admirably. “We had to do 100% UT of weld joints in 120 previously erected tanks of various sizes, diameters ranging from 7–15 m and heights from 10–36 m that would have required a huge amount of scaffolding and preparing approaches for the UNIQUE PROJECT, UNIQUE OPPORTUNITIES Molla Barkat Hussain Manager (Mechanical – QA/QC), M&M SBG grinders and UT technicians,” he points out. “Instead, by using PAUT on weld joints with rope access, we avoided scaffolding and also saved a lot of time.”

The other is the standing seam panel insulation method they adopted. In the conventional method, the insulation mattress would be wrapped, secured with GI wires, and then clad outside the mattress. “In our method, the insulation mattress and the cladding sheet were laminated to form a panel on the ground, then erected on to the surface of the tanks with the adjacent edges of the panel secured with GI clips, which reduced work at height and improved quality.”

On the digital front, Barkat mentions the implementation of the Quality App, CONQUER, that keeps the respective execution engineers informed about site observations, resulting in quick resolution, without any gaps in communication. About his work environment, he smiles, “The site team including the seniors are always helpful and we support each other for the benefit of the site.”

“I was part of the site team that established the PQR & WPS of FCAW welding process when executing the Blast Furnace Project at Tata Steel’s Kalinga Nagar Plant,” he shares proudly.

About his personal life, he shares, “I am a family man and I like spending my time with my wife, Zaheda Fathema, a homemaker and having done B.Sc. (Computers) and B.Ed., and son, Hyder Abbas. Holding him for the first time is a feeling that I cannot express,” he says, his eyes welling up with fatherly love.

A VETERAN ENJOYING HIS FREEDOM TO EXPRESS HIMSELF

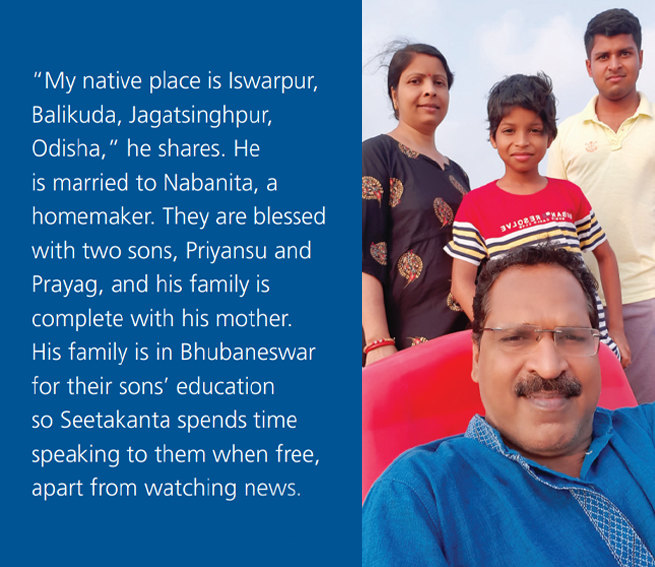

Seetakanta Panda

Assistant Construction Manager (Mechanical), M&M SBG

He is already a veteran and presently at Vedanta Limited’s Alumina Refinery site at Lanjigarh, Odisha, Seetakanta Panda is already executing his 6th project with L&T. What has impressed him throughout his journey is the freedom he has enjoyed in expressing himself, starting with his first project, the 1.6 MTPA Alumina Refinery and 3x30MW Captive Power Plant for M/s Utkal Alumina International Ltd., at Rayagada, Odisha. “There, I was responsible for handing the fabrication, erection and construction works, developing scope for 24,500 MT of Alumina Refinery and Captive Power Plant and erecting a 150 m tall multi-flue chimney and its structure using the Strand Jack Method,” he recalls fondly.

Apart from adapting new and different processes and methodologies to increase productivity and decrease the possibility of rework, he was fully accountable for monitoring the construction activities, managing resources, creating estimates & work breakdown structure, project planning, contingency plans & schedules, identifying risks within defined scope, quality, time, and cost constraints.

He shares another big achievement at his present assignment. “I completed the structure and equipment of the Hydro Cyclone Building, which is a critical structural building with limited resources and manpower by erecting structures modularly and assembling equipment at ground level,” he is visibly proud. “At my 3rd project, after completing the sheeting work on the ground, I erected the conveyor gallery with all technological structure in a single lift,” he adds for good measure.

At Lanjigarh, his two major issues have been the lack of adequate manpower and remoteness of the site. “To address the manpower issue, we have adopted mechanization wherever possible to address some of the delayed milestones like using man lifters and electric chain pulley blocks with the available manpower,” he shares. “Due to the remoteness of our site, we have a committee to screen incoming workmen, find out reasons for absenteeism, take appropriate precautionary action and take ownership during crucial periods of time.” The team monitors their monthly plans daily with chatbot, use WISA to monitor workmen availability, the Safety App and the Quality Conquer App to avoid rework. “Continuous guidance and swift decisions from my seniors wherever required and, of course, the freedom to express myself are the reasons for my continued success.” He smiles in delight.

RE-BUILDING IS ALWAYS MORE DIFFICULT THAN BUILDING ANEW

Bharath Kumar A

Assistant Construction Manager (Mechanical), M&M SBG

One of the biggest issues facing the VL Lanjgarh Project team is having to dismantle and rebuild. “When our work started in 2021, we were working in a half-executed plant, forced to dismantle the old structure because it was out of alignment,” says Bharath Kumar, with a shake of his head. The team’s challenges did not stop there: situated in a dense forest area, vehicle and manpower movement is impossible, it is difficult to find fabricated structural material and mobilize manpower in time. “We also face co-ordination problems between the existing and new structures, the existing and new BOQs.”

Despite these huge stumbling blocks, Bharath is happy with their progress thanks to some smart methods and processes. “By making panels at ground level before erecting, we have reduced the number of lifts and avoided unsafe conditions while working at heights,” he points out. Priority-wise stacking and handling of material has speeded up assembly & erection, while micro-detailing their weekly and daily plans is making it easier to achieve their targets. “If we see any deviation in our plan, we immediately find its reason and root cause to solve it at once,” he says with determination.

For erections, the team suggested temporary columns readily available at the site instead of scaffold tower structures. “We implemented after CMPC’s approval and successfully minimized our timeline, cost, and risk assessment,” he shares with a winning smile. “We achieved rafter erection within 45 days, which is the total target of 200 MT without any safety or quality deviations,” he adds.

Bharath believes in the success of teamwork especially in the construction field, where nothing is possible without helpful and supportive team members. “All my seniors are giving me full freedom to work, and team members work from their souls, night and day, to make things happen. Even during month-ends or critical erection activities, we just make it happen together as a team,” he declares with josh.

A native of Kattumannar Koil in Cuddalore, Tamil Nadu, Bharath’s life partner is Ramana Devi B, a homemaker. One of his life’s happiest moments was when he knew that they were blessed with twins, Jay Prajan B and Jay Sravan B, and holding them for the first time. Target completions at the site are also moments to cherish. His favourite hobbies are playing cricket and cooking.

An L&T-ite since 2010, Bharath feels that L&T’s success lies in the Company’s ability to keep its commitments to Clients; “that demands dedication and punctuality from all of us, working together as a family,” he says with a sense of wonder.

PERFORMING IN A GREAT WORKING ENVIRONMENT

Anuchan Mohanty

Assistant Construction Manager (Mechanical), M&M SBG

With stints at LD 3 & LD 1, Jamshedpur; COB-BPD and PLTCM, Jamshedpur; COB KPO, Kalinga Nagar; and BPP, COB, and BF #2, JSW Dolvi, Anuchan Mohanty brings rich mechanical experience to his role at the Vedanta Lanjigarh Project. “Erecting three 45 MT pipe rack galleries and unloading and erecting four 184 MT heaters, each in a single working day, were standout moments for me,” he states enthusiastically.

Speaking of his previous project stints, Anuchan specifically mentions completing 10,000 IM of piping erection in a single day at the Tata KPO Bi-Product Plant. “In addition, we commissioned and completed the PG test of 12 pumphouse lines in a month,” he adds, proud of his achievement.

At the Lanjigarh Project site, Anuchan has had to face challenges in strengthening, modifying, and finishing the misaligned old structure. Space constraints to modify the structure and civil foundation were other hurdles. “It required detailed discussions, and once we received the Client’s go-ahead, we carried out the modification works to suit the site conditions,” he shares. “We also agreed on an additional rate amendment for the civil retrofitting and structural strengthening works.”

Tandem lifting of digester vessels, modular erection of the digester vessel support structure, and pipe rack gallery have been some unique initiatives implemented by Anuchan and team. “We also erected 20 heaters of 943 MT and completed the structural modification, all within 45 days,” he mentions with evident delight.

Digital platforms are helping the Lanjigarh Project team monitor daily progress. “By creating 3D models, we can easily plan heavy and tandem erections, and Apps have simplified recording observations on safety and quality aspects too,” remarks Anuchan, adding that his seniors and fellow teammates have been pillars of support. “They have always provided the required resources, and their ideas and experiences continue to help me improve.”

A native of Cuttack, Odisha, Anuchan loves playing cricket. He is married to Saishradha, a homemaker, and the day their daughter, Diksha, was born is his most memorable moment.

Anuchan’s favourite aspect of L&T is its ‘unity in diversity’. “We’re all in it together! I love how each one of us L&T-ites is committed to working towards a common goal, irrespective of our backgrounds,” he comments earnestly as he signs off. “It’s the perfect recipe for creating a great working environment!”

“L&T MAKES YOU A STRONG

DECISION-MAKER”

Gaurav Kumar

Assistant Construction Manager (Civil), M&M SBG

Ever since joining L&T in 2011, Gaurav Kumar has been a part of several coal handling plants in thermal power and refinery projects and holds an especially fond memory of his time at the Nabha Super Critical Thermal Power Project in Rajpura in 2012–14. “I met Mr. A. M. Naik when I was at the project, and he appreciated me for my work!” he gushes, smiling from ear to ear.

Currently at the Vedanta Lanjigarh Project, Gaurav is in the civil department, implementing the latest tools and tackles at site. “We have adopted technologies like rebar anchoring, diamond cutting, and controlled blasting to expedite process,” he informs. The rebar anchoring is used for pipe racks with hard rock at base, while core cutting, diamond cutting, and control blasting are for new foundations coming under the existing structure. To settle the soil while backfilling with space constraints, the team proposed to the client to go for crusher dust filling. In addition, Gaurav and team use reinforcement couplers to minimize the wastage of steel. “The PPT hydro cyclone pile cap and pipe rack foundation are very critical due to the soil conditions, high water table, and narrow space,” he adds. “We completed all these with our dedicated efforts and support from the management.”

“There have been some unavoidable changes, for which we had to work extensively with the engineering team to prepare fresh drawings that suited the site conditions and, at some places, had to construct foundations where the water table was too high,” Gaurav notes. “But we have been able to overcome this through continuous dewatering and drain arrangements.”

“L&T makes you a strong decision-maker,” states Gaurav, “giving you the self-confidence to execute any job in any condition.” He is all praise for his Project Manager Sanjay Saha: “He always inspires the team to gain learnings from our work that will help fulfil the customer needs as well as help us in our own personal growth.” He is thankful for digital apps that have helped them continuously monitor their daily work progress against the daily plan. “That has been a key factor for the progress we have made within the time limit.”

Hailing from Kota, Rajasthan, Gaurav is married to Pratiksha, a share market broker. He loves reading and travelling.