Bringing science to the art of safety risk profiling

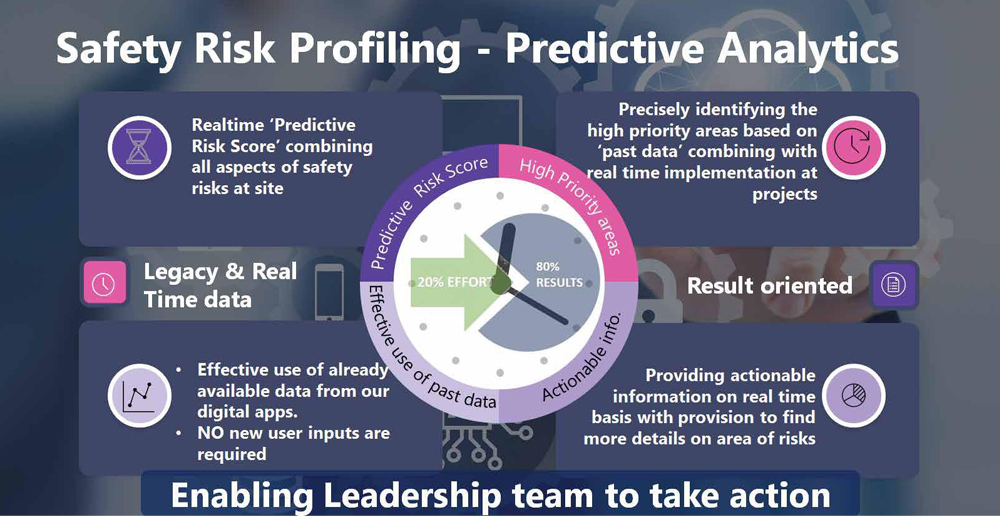

Introducing B&F’s ‘Predictive Analytics – Safety Risk Profiling’ model

Risk profiling is tricky, as every organization has its own risk profile. In L&T Construction, every business and every project have their own unique risk profiles; therefore, a one-size-fits-all approach can be inefficient and risky. A risk profile examines the nature and level of threats faced, the likely occurrence of adverse effects, the level of disruption and costs associated with each type of risk, and the effectiveness of controls in place to manage those risks. Safety risk profiling is all about identifying the right risks and prioritizing them for action.

The B&F central EHS team found that although they possessed a large amount of data generated from inspections and incidents, the leadership team still required multiple parameters for actionable insights. “It was almost a case of water all around but not much to drink,” remarks P Nagarajan, Head – EHS, B&F IC. “There was a dearth of data-driven methodologies to accurately assess the safety risk profile of projects. We did not have any insights on project lifecycle– based risk or any refined data based on previous experience to prevent accidents other than accident-specific learnings.”

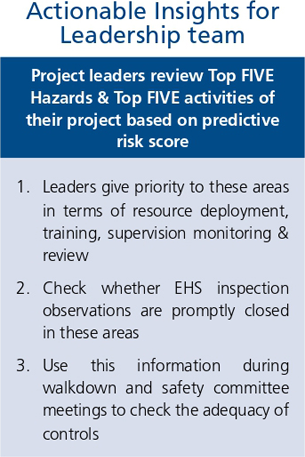

The biggest advantage of safety risk profiling is that it makes EHS decision making faster and more effective, for the model throws up actionable information to manage prioritized risks.

P Nagarajan

Head – EHS, B&F IC

To introduce a dynamic, data-driven risk profiling tool, a team was put together comprising Anup Avinash Kadam, Business Analyst – Corporate Digital; Rajesh, Manager – EHS, B&F IC; Dushyant Bharadwaj, Senior Associate (Data Analytics) – COEAA Team, DC; and Suresh B, Senior Engineer – EHS, with M Nachiappan, DGM – EHS, B&F IC, in the lead to create a programme that aimed to bring science into the art of safety risk profiling. Adopting a phase-wise approach, they started with primary research leading up to roll-out and implementation of the solution.

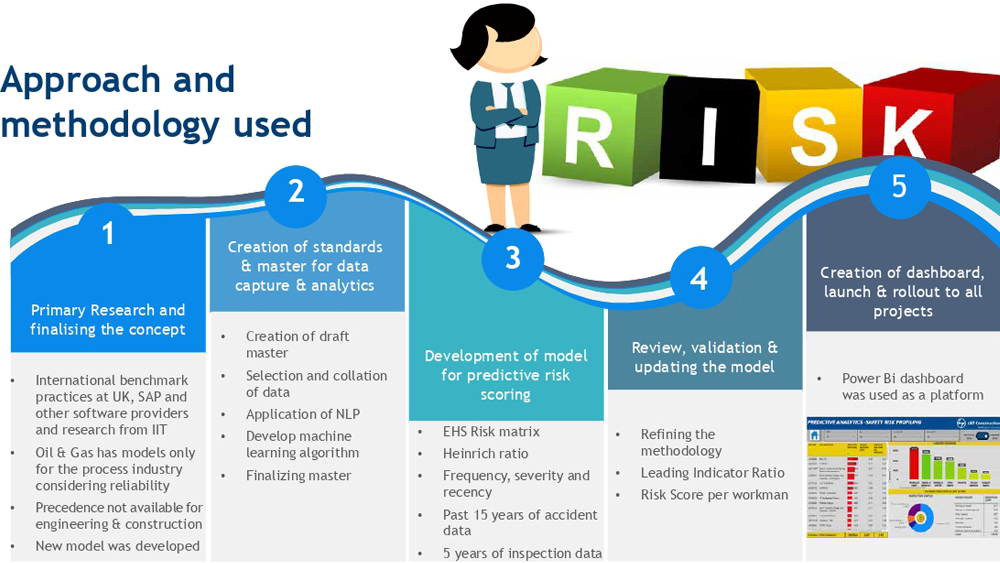

Researching and developing the concept

The team’s first task was to conduct primary research in using data analytics for EHS practices specially to predict risk potential, which included major ERP solution providers, international benchmark practices in the UK, proprietary EHS software providers, and research papers from leading institutes, including IITs. One major impediment was the absence of precedents. “Although the oil & gas and other process industries had their own risk prediction models and methods, they were specific to their industries and applicable only for process safety and not for the engineering and construction industries,” points out Nachiappan. Even though safety risk profiling is an internationally recommended benchmark practice, it was only based on individual/ team assessments, and there were no standard data-driven methodologies or practices applicable for the construction industry.

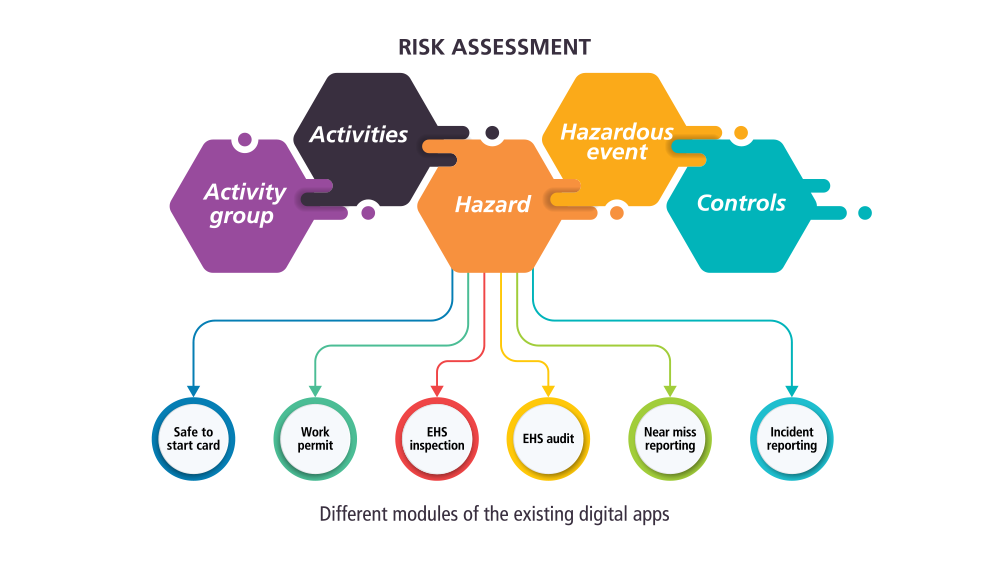

The team’s task was therefore cut out: a new safety predictive risk model had to be developed suitable for B&F’s operations. “We analysed our existing safety indictors available on various digital platforms and developed a new concept that we ran past selected senior EHS team members for feedback and validation,” adds Nachiappan.

Creating a master and standards

Critical to the team’s effort was the need to change the way EHS data was being captured and analytics derived thereof, and hence their next task was to create a master and new standards, for which they implemented the five steps:

- Create the draft master

- Select & collate data

- Apply NLP

- Develop ML algorithms &

- Finalize the master

Significant tools used in these steps were Natural Languages Processing (NLP), Machine Learning (ML) algorithms, and rankings based on dictionaries. More than 15 years of incident data and 5 years of inspection data served as a base for predictive risk modelling. The legacy data used had more than 8 lakh rows! The masters were developed and integrated as part of the EHS Management System (EHSMS), and a revised EHSMS manual was rolled out across B&F in November 2021. “Our safety apps were updated to accommodate these changes, including the provision to obtain standards data for all the transactions,” informs Nachiappan. “After this change, we were able to get real-time data that could be reliably used for predicting risk modelling,” he says with a slight smile.

Development and validation of the model

The predictive safety risk model was developed based on well-known accident prevention models like the Heinrich triangle, risk-based approach, and B&F’s safety risk matrix. “Predictive risk score is devised as a function of Frequency, Severity, and Recency, and the previous 30 days of real-time data is used to compare with past data to calculate a predictive risk score,” says Nachiappan.

Thereafter, the output from the predictive risk models were logged and closely monitored. Change trends in the risk score were compared to other leading indicators and physical conditions through site visits and audits. A few modifications were made to the model to improve results, which included changes in methodology, leading indicator ratio to understand the reliability of the model, and risk score per workman to easily compare across major, medium, and small projects.

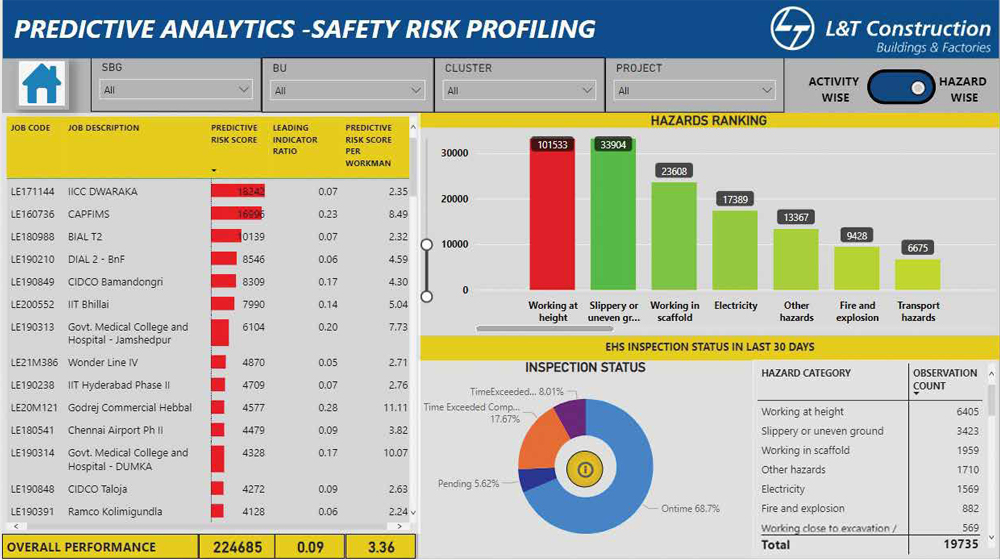

Proof of the pudding

Having created the model, the time had come to put it to practice, for which Microsoft Power BI was used to present the insights on visually attractive, intuitive, and interactive dashboards, which help engineers understand the risk scores better, drilled down to granular levels for actionable information.

The ‘Predictive Analytics – Safety Risk Profiling’ model was formally launched by Whole-Time Director & Senior Executive Vice President (Buildings), M V Satish, during the EHSMS Management Review Meeting with all senior leaders of the IC and clusters on 8 March 2022, and cascaded to the leadership at the clusters and projects. All the roll-out sessions were through webinars that included demos of the live platform. A total of 750 employees including cluster leaders, project managers, and section in-charges have been covered.

The renewed focus on priority areas helps to improve compliance at project sites and identify pockets of concern for immediate action. The model will help us set up internal benchmarks for predictive risk scores based on the type of projects like airports, hospitals, factories, etc. and the execution stage of the project.

M Nachiappan

DGM – EHS, B&F IC

“The biggest advantage of this model is that it makes EHS decision making faster and more effective, for the model throws up actionable information to manage prioritized risks,” sums up Nagarajan.

The ranking of high risks specific to operations are on a real-time basis, focus areas are highlighted for corrective actions to prevent accidents, and the ‘predictive risk score’ gets reduced based on actions taken on the prioritized risk areas.

The model has been integrated with all the regular EHS and operational reviews and is an ideal one-stop solution to review EHS performance. “The renewed focus on priority areas helps to improve compliance at project sites and identify pockets of concern for immediate action,” alerts Nachiappan. “The model will help us set up internal benchmarks for predictive risk scores based on the type of projects like airports, hospitals, factories, etc. and the execution stage of the project.”

As the model finds greater acceptance and more projects tighten their EHS standards, here’s wishing the B&F EHS team the very best to achieve Mission Zero Harm!