Sustainability is simpler than you think!

Positive carbon footprint initiatives at the BHEL Ennore Project

After crossing a landscape peppered with chimneys and cooling towers of the surrounding power plants, one is relieved at the BHEL Ennore project site, greeted by clusters of plants and trees that stand in stark relief to the otherwise brown terrain. Initially spearheaded by Sanjeevi Perumal, the previous project manager, the team led by the current Project Manager Balamanikandan have planted 300 saplings in a location that used to be a fly ash dumping ground and, in the process, made a significant contribution towards protecting Planet Earth.

These initiatives were planned right from the start of the project by Mr. Sanjeevi Perumal. Being a first, we decided to take a risk with the implementation. But the calculations show a proper picture of the savings made, which is certainly satisfying.

Suresh B

Assistant Manager – EHS

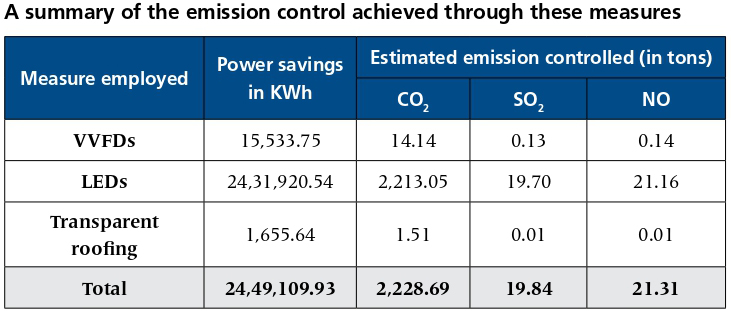

Through some prudent ESG initiatives like installing Variable Voltage Frequency Drives (VVFDs), transparent roofing, and LED lights, the team has managed to conserve a whopping 2,449.10 MW of energy and reduce 2,228.69 tons of CO2 emission.* “These initiatives were planned right from the start of the project by Mr. Sanjeevi Perumal. Being a first, we decided to take a risk with the implementation,” remarks Suresh B, Assistant Manager – EHS. “But the calculations show a proper picture of the savings made, which is certainly satisfying!” he beams.

*All figures presented in this article reflect data from December 2018 to June 2022

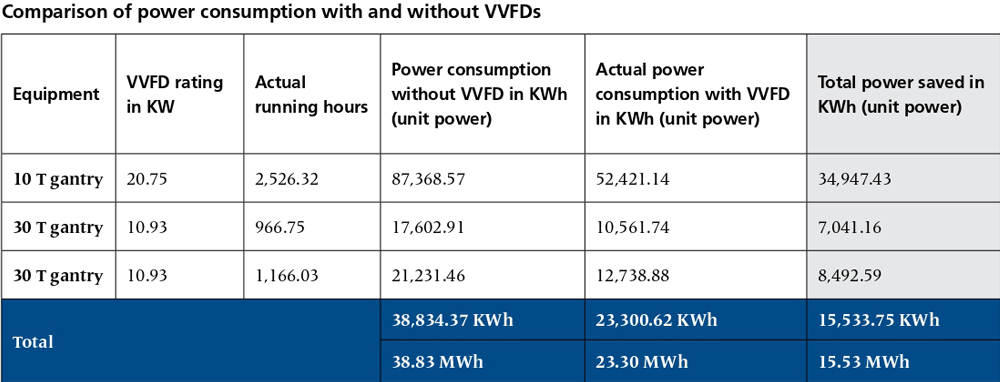

60% reduction in power consumption

Three gantry cranes – two of 30 T capacity and one of 10 T capacity – have been fitted with VVFDs to regulate the power supply, which has resulted in more than a 60% reduction in power consumption. The gantry crane motors are driven through the VVFDs to control ramp-up and rampdown of the motor during start and stop, respectively.

Depending on the load being lifted by the crane, the VVFD controls the voltage delivered to the equipment, which ensures that the motor does not consume more power than it needs, and protects the equipment by automatically cutting off if the load exceeds the limit and also safeguards the user from sudden jerks during the start and stop of the gantry crane.

SK A Gulamrashul Baseer

Manager – P&M

Although VVFDs have been in use across projects, this is the first time they have been used specifically for power conservation. SK A Gulamrashul Baseer, Manager – P&M, explains that they not only optimize the power consumed but also make the operation safer. “Depending on the load being lifted by the crane, the VVFD controls the voltage delivered to the equipment, which ensures that the motor does not consume more power than it needs, and protects the equipment by automatically cutting off if the load exceeds the limit and also safeguards the user from sudden jerks during the start and stop of the gantry crane.”

Another significant advantage of VVFDs is that they are reusable. “They just have to be dismantled and reinstalled where required,” informs Baseer. “VVFDs can be used wherever motors are used. Where there is heavy consumption of power, with high-capacity cranes running at high speed, the variable voltage can help reduce the consumption.”

VVFD installed in the 30T gantry

30T gantry at the fabrication yard

Lit by natural light

One of the team’s more innovative measures has been to use transparent roofing to harvest natural sunlight. The sunlight shines through these sheets to illuminate the office areas, eliminating the use of electrical lights during the daytime. Duly inspired, the team is planning to have transparent roofs for the new stores being built.

LEDs light the way

Power-saving LED lights across the site are another major contributor to the power conservation. The LEDs have been used instead of the conventional highpressure sodium vapour (HPSV) lamps.

Reducing the GHG footprint

As per the CO2 Baseline Database for the Indian Power Sector, Ministry of Power, India, it is inferred that to produce every unit of electricity, 0.91 kg of CO2, 0.0081 kg of SO2, and 0.0087 kg of NO are being released into the environment.

Has all this been worth it?

When asked what could cause projects to hesitate to implement these approaches, Suresh says with a practical shrug, “Well, the main obstacle would be the mindset.

Transparent roofing uses natural sunlight

Return on investment is a primary point to consider. If the project duration is too short, say less than one year, then sites will hesitate to invest.” He affirms that larger the project, more the savings realized.

For an investment of Rs. 23.6 lakhs to implement their energy-saving initiatives, the site’s electricity billing has reduced by Rs. 3.65 crores, as on 15 June 2022. This translates to savings to the tune of Rs. 3.42 crores!

With all the talk about global warming, these measures are a testament that sustainability need not be rocket science. We are seeing our relatively simple measures show results, and we hope this inspires more projects to take up similar positive carbon footprint initiatives.

Balamanikandan

Project Manager

“With all the talk about global warming, these measures are a testament that sustainability need not be rocket science,” remarks Balamanikandan. “At the BHEL Ennore Project, we are seeing our relatively simple measures show results, and we hope this inspires more projects to take up similar positive carbon footprint initiatives.”

The BHEL Ennore project team