Waste warriors rise to the plastic challenge!

The millions of tons of plastic swirling around the world’s oceans are creating a furor, but plastic pollution arguably poses a bigger threat to plants, animals, and human beings. Very little of the plastic we discard every day is recycled or incinerated in waste-to-energy facilities. Much of it ends up in landfills, where it may take up to a thousand years to decompose, leaking potentially toxic substances into the soil and water. The impact of microplastics in soils, sediments and freshwater could have a long-term negative effect, so it is high time that as a global community we wake up to this threat and act.

Eight project sites of WET IC have woken up to this plastic threat and have begun to act. The Pune ESR & GSR, the Pune 24x7 Packages — 1, 2, 3, 5, 6, the Brahmani, and the Navda to Chavand Bulk Pipeline projects are championing a ‘Go Green Campaign’ initiated by L&T HQ at their sites and offices, as a part of their EHS objectives.

The project sites are on a mission to transform construction waste to usable material, to reduce their reliance on single-use plastics and increase the utilization of recycled plastics. Their collective effort to use plastic wastes is both economically beneficial and offers alternative materials for construction.

Plastic contains toxic pollutants that damage the environment and pollute land, water, and air and can take hundreds or even thousands of years to break down.

Niwas Salunkhe

Project Manager, Pune ESR and GSR

Plastic is extremely durable, highly flexible, and inexpensive to produce and one of the most popular materials used across the world. “Plastic contains toxic pollutants that damage the environment and pollute land, water, and air and can take hundreds or even thousands of years to break down, so the damage to the environment is long-lasting,” warns Niwas Salunkhe, Project Manager — Pune ESR and GSR. “Hence, plastic waste management is critical.”

Central collection of waste plastic

Re-use and recycle: Plastic waste to plastic polyfuel / granules

“Construction projects see a lot of waste, some of which can be re-used, recycled or upcycled to drastically reduce wastage,” states Rajesh C, Project Manager — Pune 24x7 Packages 2 & 6. “At our project, we have taken the initiative to daily collect the plastic waste generated in our work area and in our surroundings, which are then handed over to agencies for recycling and producing by-products for further use.”

Plastic waste to plastic polyfuel

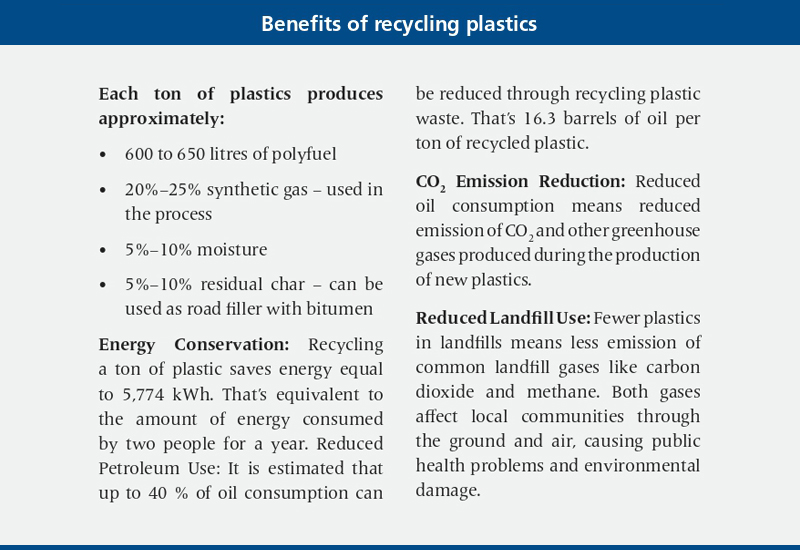

At the Pune 24x7 Packages — 1, 2, 3, 5, 6 and Brahmani project sites, plastic waste is recycled to plastic fuel, which is used in boilers, cement factories, steel mills, glass factories, etc. as diesel, coal, or wood substitutes.

At our project, we have taken the initiative to daily collect the plastic waste generated in our work area and in our surroundings, which are then handed over to agencies for recycling and producing by-products for further use.

Rajesh C

Project Manager, Pune 24x7 Packages 2 & 6

“Recycling plastic waste into fuel (polyfuel) is diverting plastic waste from landfills, which lowers the carbon footprint,” says Harshal Jagdale, Project Manager — Pune 24x7 Package 5. “We have started collecting waste plastic from sites like colour paint bags, food packaging bags and bottles to effectively recycle them. It has been ingrained into our workforce that plastic waste management is important to reduce pollution, and everybody plays an integral role to reduce the carbon footprint.”

Plastic-derived fuels produce cleaner burning fuel than traditional sources due to their low sulphur content, which can be directly used for burning in kerosene stoves, boilers, furnaces, certain types of gensets and the like. The char produced is a non-hazardous waste.

It has been ingrained into our workforce that plastic waste management is important to reduce pollution, and everybody plays an integral role to reduce the carbon footprint.

Harshal Jagdale

Project Manager, Pune 24x7 Package 5

At the Pune ESR & GSR sites, plastic waste is recycled into plastic granules that are used in compression moulding, highly reinforced composites, powder coating and 3D printing.

Plastic waste to plastic granules

The power of people buy-in

The success of an environmental initiative is in the buy-in from the workforce, believes Manoj Rajendra Chavan, Project Manager — Pune 24x7 Package 3. “Everyone needs to understand their role and be motivated to play their part. However, you need to ensure that your new guidelines and initiatives are clear, so that they know their goals.”

The employees of the project sites undergo site specific training and are also trained on various areas including Environment Management RBT and Waste Management. The waste collection & segregation is conducted on a daily, weekly, monthly basis to minimise waste accumulation at sites and keep work areas neat and orderly. Regular housekeeping and waste minimisation campaigns help maintain aisles and floors free of slip and trip hazards and remove waste materials and other fire hazards.

Everyone needs to understand their role and be motivated to play their part. However, you need to ensure that your new guidelines and initiatives are clear, so that they know their goals.

Manoj Rajendra Chavan

Project Manager, Pune 24x7 Package 3

“Our employees and workmen are educated periodically to take this initiative to the next level,” says Sanjay Saha, Project Manager — Pune 24x7 Package 1. “We have all adapted to sustainable ways to collect, recycle and reuse plastic waste thanks to the continuous efforts of the EHS team.”

We have all adapted to sustainable ways to collect, recycle and reuse plastic waste thanks to the continuous efforts of the EHS team.

Sanjay Saha

Project Manager, Pune 24X7 Package 1

Durgesh Sonavane, Site Engineer — Pune ESR and GSR, sums up aptly, “We are responsible for plastic waste, and hence need to clean the environment for living by reducing the use of plastic. I have been working at L&T for the past two years and can proudly say that apart from project work, we are also taking care of the environment in our own little way through plastic waste collection and recycling initiatives. Charity begins at home,” he reminds.

Ensuring that the plastic doesn’t end up in our oceans or pollute the environment requires a coordinated effort to improve collection systems, and recovery infrastructure.

Subrata Karmokar

Project Manager, Navda to Chavand Bulk Pipeline Project

Way forward — Working with the communities

The sites are making the ‘Go Green campaign’ more robust by taking it to the neighbouring communities to conduct awareness sessions for the residents, with strategic cleaning campaigns planned for schools and homes. Weekly plastic collection drives from employees, their families, and workmen have been planned, and the collected waste will be handed over to recycling agencies. All are encouraged to use eco-friendly e‑bikes, cars, and battery-operated vehicles at the sites.

We have planned various local plastic collection initiatives and cleaning campaigns for schools, parks and ponds around our project sites to create awareness about environmental issues.

We will sustain the momentum.

Subrata Karmokar

Project Manager, Navda to Chavand Bulk Pipeline Project

“Ensuring that the plastic doesn’t end up in our oceans or pollute the environment requires a coordinated effort to improve collection systems, and recovery infrastructure,” explains Subrata Karmokar, Project Manager — Navda to Chavand Bulk Pipeline Project. “We have planned various local plastic collection initiatives and cleaning campaigns for schools, parks and ponds around our project sites to create awareness about environmental issues. We will sustain the momentum,” he adds with a smile.

Our efforts will create an effective afteruse plastics economy which will create more material value and increase resource productivity.

Nilesh Kumar Jain

Project Manager, Brahmani Project

At the Brahmani Project, Nilesh Kumar Jain, Project Manager, looks pensive as he mentions the plans for more plastic collection and cleaning drives for communities around the project sites. “Our efforts will create an effective after-use plastics economy which will create more material value and increase resource productivity.” He admits that they still have a long way to go, as he sips from a steel water bottle at a functional no-frills office which is plastic-free.