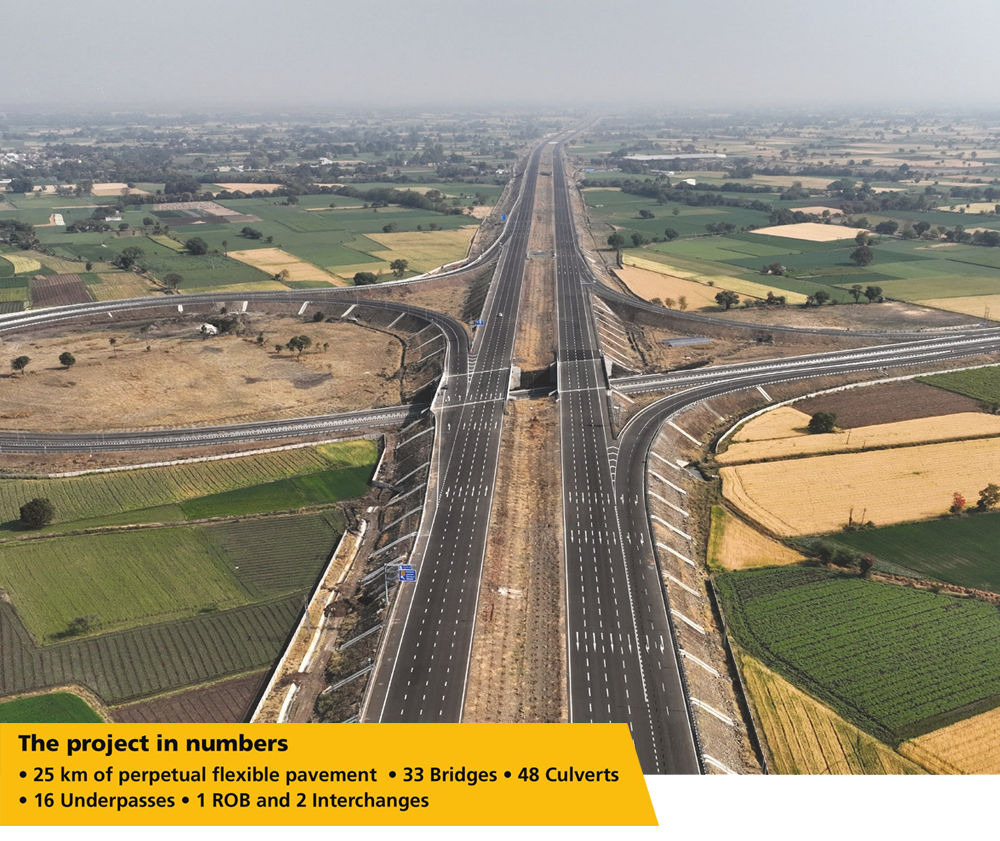

MADHYA PRADESH EXPRESSWAY PROJECT. DELIVERED TIMELY. IN FACT, 61 DAYS AHEAD OF TIME.

RREC were given the mandate to execute Package No. 22, near Ratlam, of the Madhya Pradesh Expressway which is part of the new 8-lane access-controlled expressway being planned by the National Highways Authority of India (NHAI) from New Delhi to Vadodara, soon to be the country’s longest expressway under the flagship Bharat Mala programme. Considered an important project and a vital link to establish road connectivity to and from the country’s capital, the project team were impressed upon by NHAI to complete and deliver the project in 2 years flat when awarded

in June 2020.

“Delivering road projects in time are rare because such projects are almost always hit by challenges, many a time unforeseen or out of the control of execution teams often leading to delays and overruns,” cautions Project Director,

J Jeeva David. “However, since the client had reposed so much faith in our capabilities to deliver on time, we decided to go for it,” he pumps his fist with josh. “In fact, on the very first day of the project, our BU Head, R K Bansal, wished and urged us that we should collect full bonus for the project. We accepted the challenge and took an oath that we would attain a bonus, which is again quite rare,” smiles Jeeva. “It demanded a different approach and we started to prepare ourselves to achieve a goal of completing the project 6 months ahead of the delivery date.”

“On the very first day of the project, we took an oath that we would attain a bonus for the project, which is again quite rare that demanded a different approach and we started to prepare ourselves to achieve a goal of completing the project 6 months ahead of the delivery date.”

J Jeeva David

Project Director

The pandemic – the first roadblock

Mid 2020 with the pandemic raging globally, the MPEP team were preparing to both counter the pandemic-induced roadblocks and hit the road running.

“One of our biggest challenges was to retain manpower at site during the 2nd wave of the pandemic and hats off to our admin team for their support in not only taking care of those suffering but regularly providing food, medicines and medical facilities especially during the lockdown,” recalls Assistant Construction Manager (Civil), Amit Kumar Malik.

“Numerous workmen and staff were hit by Covid but we broke the shackles and with full support of the BU head along with all the HQ department heads, we forged ahead to complete the project 61 days ahead of schedule,” remarks a triumphant Planning In-charge, Dhananjaya N V. In the process, they become the first project to be completed out of the 9 packages being executed by various companies in the MP section of the Delhi Mumbai Expressway.

“Numerous workmen and staff were hit by Covid but we broke the shackles and with full support of the BU head along with all the HQ department heads, we forged ahead to complete the project 61 days ahead of schedule.”

Dhananjaya N V

Planning In-charge

Timely mobilization – the key to timely delivery

Like in a T20 match where a slow start can seriously adversely impact a chase, project teams must get cracking from day one to keep up with the asking rate and timely mobilization is the key first step. At MPEP, all the key resources, people, plant, machinery & equipment were mobilized well in advance, all the statutory permits obtained, including that for borrow earth, with the result, concreting for the main structures along with earth works commenced on first day itself.

“An index of our level of preparedness to take off is that we started concreting for structures on November 19th, 2020, just two hours after receiving the NTP clearance,” enthuses Jeeva, “and commenced girder erection for the major bridge on May 7th, 2021, without wasting even a single day.” With such focus and planning, it is little wonder that they completed all sub structure work before the advent of the monsoon that year.

Daily monitoring of works is another vital contributor for project success and every member of the team shouldered the responsibility of constantly keeping their daily targets in sight, and ensuring their achievement by the end of each day. “Finishing works commenced almost a year ago and we focussed to complete work in all respects km by km which is why we were able to achieve our primary objective of delivering ahead of time,” says Project Manager, Anil Kumar Sachan, with a broad smile.

“Finishing works commenced almost a year ago and we focussed to complete work in all respects km by km which is why we were able to achieve our primary objective of delivering ahead of time.”

Anil Kumar Sachan

Project Manager

Overcoming mountains of challenges at site

Resolving the land issues to kickstart preconstruction activities was a major hurdle the team had to overcome with patience and strenuous follow-up.

A clever ploy the team adopted to speed up construction was to lay an access road all along the alignment that made movement of men, material, and machinery extremely quick and easy. “Another huge challenge was to execute the ROB involving the excavation of 1.2 lakh cum, 18 m deep hard rock in a limited time frame of just 4 months,” shares Anup Kumar, Construction Manager (Civil). In addition, the team had to continuously dewater when working at such depths and the flow of water severely affected the material shifting of formwork & reinforcement. “Further, in the superstructure works at the ROB, girder shifting (37.5 m / 105 MT each) & erection at location were challenging due to a limited working area,” adds Anup.

Another tall challenge was to deliver material to site as the project was divided into 2 sections, divided by a steep hill. “Initially, we had to travel about 40 km from main camp to site through Ratlam city, and heavy vehicles could only move during the night shift,” laments Subhasish Rout, Deputy General Manager (Mech), whose team provided the solution of preparing a ramp by cutting the hill for the smooth movement of men and material, which paved the way for early completion.

The team encountered black cotton soil near Ratlam that severely disrupted preconstruction activities and schedules. “It was tough to clear the land, bridge the canals and make the approach motorable for which we had to blast to loosen the top surface of rocks and then use the same in the embankment,” sighs Assistant Construction Manager, Abhinav Kumar Singh but he immediately brightens up. “This is where the insistence of JJD sir and Anil sir to only use the project access road for transportation paid off. We started moving along the entire alignment from the first month itself that went a long way to achieve our targets in time,” he says with the vigor of success.

“It was tough to clear the land, bridge the canals and make the approach motorable. This is where the insistence of JJD sir and Anil sir to only use the project access road for transportation paid off. We started moving along the entire alignment from the first month itself that went a long way to achieve our targets in time.”

Abhinav Kumar Singh

Assistant Construction Manager

The team had several other not-so-minor issues to tackle: land issues, non-availability of soil, and scarcity of water. In fact, the last issue resulted in the team unable to attain the optimum amount of moisture in the soil.

Some innovations. Many awards.

Jeeva is appreciative of the mix design SMA (Stone Matrix Asphalt) they adopted for the pavement top layer, with continuous monitoring and testing. “The raw material was meticulously tested for lime, cellulose fibre, and bitumen aggregates,” informs Santosh Kumar Shukla, Assistant Manager, QA/QC. “In fact, we set up a lime purity testing arrangement at site before the raw material was fed into the plant.” The team’s total requirement of lime was 6,500 MT and soon they faced a shortage. To mitigate this, Santosh, with the team, identified a lime factory at Borunda village Rajasthan, stayed put there for a week, conducted lime purity tests, confirmed availability & dispatched the

lime on time.

“The raw material was meticulously tested for lime, cellulose fibre, and bitumen aggregates. In fact, we set up a lime purity testing arrangement at site before the raw material was fed into the plant.”

Santosh Kumar Shukla

Assistant Manager, QA/QC

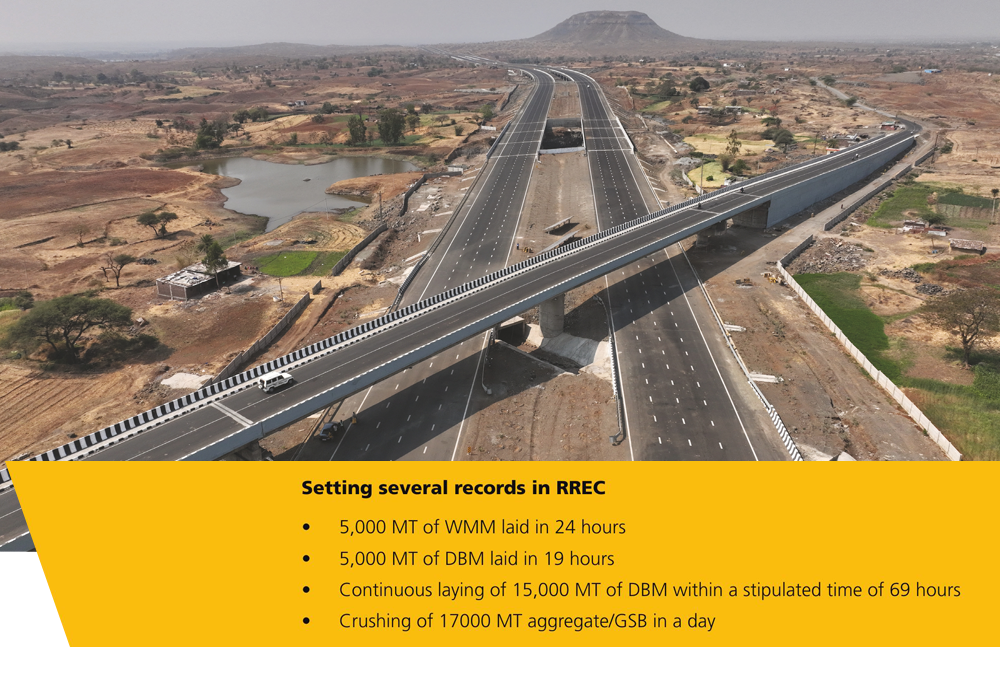

“As a team, we achieved an average concrete pour of 450 cum per day and completed 15,000 cum of hard rock excavation for the structure foundation in a single month and all the footing excavation for a major bridge.” shares Anil. “but through all this we never lost focus of safety, quality, customer trust and delight.” The result for their efforts was the Best Contactor Award from the client, NHAI, and another for achieving the target within the timeline in the Madhya Pradesh section of the Delhi Mumbai Expressway. Within RREC, the project won the Quality Award and finally the L&T Construction Timely Delivery Award that Jeeva received from SNS was truly an icing on the cake.

“Single-mindedness of purpose, motivation and a never-say-die attitude are the reasons for this truly impressive performance by Jeeva and his team at MPEP.”

R K Bansal

BU Head

“Single-mindedness of purpose, motivation and a neversay-die attitude are the reasons for this truly impressive performance by Jeeva and his team at MPEP,” sums up BU Head, R K Bansal. “We were awarded the project at the height of adversity in the form of the pandemic and right along we had to face and overcome several huge challenges, but the way the team stuck to their guns, and delivered is the stuff that we L&T-ites are made of. Kudos to all!”