PT&D IC SITES POWER BACK INTO ACTION

For a business spread across geographies, PT&D had stepped up the momentum early on across the Middle East where project operations continued with partial restrictions. In Africa and India, action began after the unlock with the breaking down of work processes, taking up of feasible fronts and following the SOPs to achieve the immediate milestones. PT&D’s digital prowess gave it the edge to address many of their pandemic-caused workplace challenges; innovative construction methods, safety initiatives and value engineering further helped to up the ante. It is interesting how a multi-pronged work approach paved the way for projects across various businesses to succeed in their back-to-work endeavours.

A three-in-one project

Having set a steady pace at the 400 kV Morepule B–Orapa-Mawana project in Botswana, Project Director, Nicholas van der Mescht, was in the thick of action with the tower parts reaching different areas of the alignment. “There are 3 projects in the roll out for L&T across Phase 1 and 2 schemes. A 400 kV transmission line from Morepule B to Orapa, another 400 kV line from Orapa to Maun and a 400/220/132 kV substation at Mawana,” he briefs. Between 2nd and 16th March, the team had received 155 tower parts after which the level

5 lockdown was announced. “Processed steel, a vital material for our execution, was held up in South Africa while at sites there was a line of other essentials to be ticked such as safeguarding plant & machinery across the alignment, arranging accommodation and essentials for about 220 expat workmen based at our camps to

ensure their well-being.”

“We had planned to add to our workforce in early January, well before the lockdown,” indicates Nicholas, “Workmen were already recruited and awaiting emergency work permits from Botswana but the pandemic prevented the process.” However, when site operations resumed on 25th May, Nicholas and team had set their priorities right to step on the pedal. “Our immediate focus was to commission the 220 kV Lethalakane to Orapa 17 km line as most of the major works like guy fittings and stringing had been completed before the lockdown. We immediately mobilised the crew at this section and achieved the milestone on 31st July.”

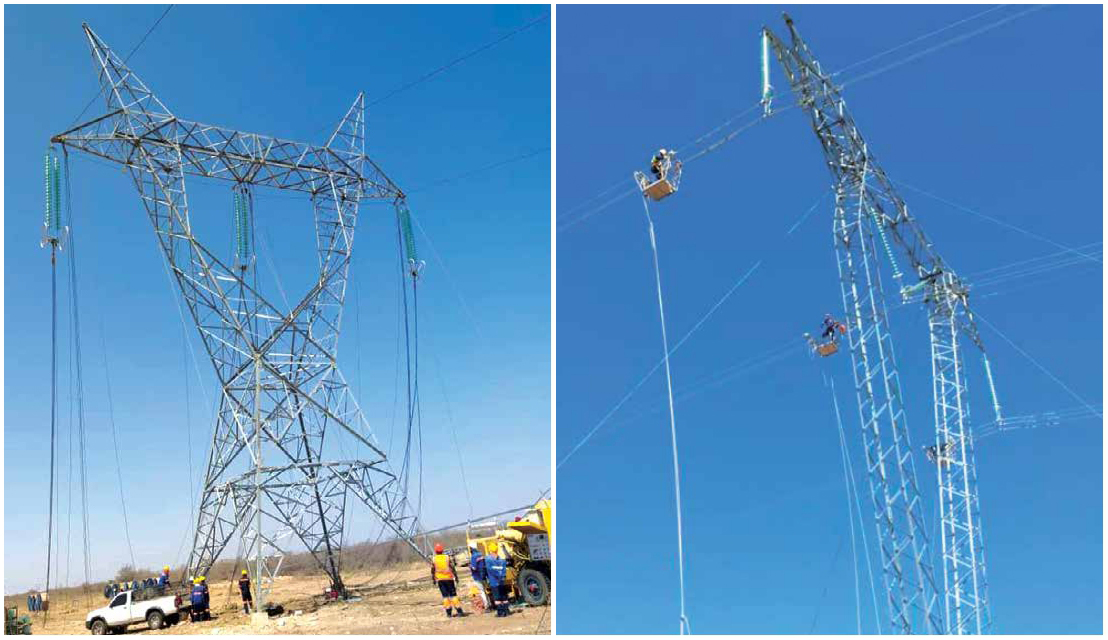

Stringing works across the 400 kV Morepule B–Orapa-Mawana Project, Botswana

Another critical task was to replace the earth wire with OPGW on an existing 132 kV line to connect Maun with Mawana, our newly built substation, while the line was energised. “We sourced skilled workmen from South Africa, proficient in working close to live lines.” However, the challenge was much more than they had anticipated for the first 9 expat workmen had to undergo a prolonged process to exit South Africa and enter Botswana, held for nearly 3 weeks at the border to complete the statutory regulations as per the requirements of both the countries. “After quarantine, they could join the ground workers only after a secure process,” says Project Manager, Hemananda Chowdary. “However, having learnt our lesson, the process with the next batch of expats was slightly easier and now all the workmen are deployed on the lines.” Despite the challenges this work was completed on time and testing at Mawana Substation has commenced.

Tower erection at 400 kV Morepule B–Orapa-Mawana Project, Botswana

Botswana’s reliance on South Africa for diesel fuel caused a huge shortage during the early days of unlock. “It was extremely difficult to manage the fuel requirements of our plant & machinery. Likewise, materials were being delayed by 4-5 days to reach our site due to clearance and screening regulations at the border,” Planning Engineer, Ganesh Kumar points out. “This affected our production as the site teams were retrofitting towers faster than the deliveries and hence, we had to slow down the process and engage in less critical activities.” For the records, between 14th May and 15th September, 367 tower parts were received at site and work is in full swing now with 288 expat workmen engaged across fronts.

“We have completed the highest tower erection in Botswana, finalized 14 out of the overall 24 outages and achieved over 200 km of conductor and OPGW stringing works.”

Nicholas van der Mescht

Project Director,

400 kV Morepule B–Orapa-Mawana project, Botswana

Nicholas and team are closing in on their milestones with almost 97% of LOT 1 & 2 works achieved. “We have completed the highest tower erection in Botswana, finalized 14 out of the overall 24 outages and achieved over 200 km of conductor and OPGW stringing works,” he shares, appreciative of the success of his team.

Overall view of the PAHW Substation, Kuwait

Key breakthroughs in the Middle East

At the PAHW Substation Package 1148 in Kuwait, Project Manager, P. Senthil Raja, had to mitigate a series of partial lockdowns, mostly from evening to the early morning hours. Their workmen strength had reduced to 200 while with all factories closed, supplies had dried up. Mobilizing skilled workmen from India was becoming increasingly difficult and hence the team had to manage with the existing available resources. “Improvisation was key for our movement,” mentions Senthil. “Work inspection schedules were aligned as per the client’s feasibility with a provision of one client engineer covering 3 stations unlike the pre lockdown phase when one engineer was dedicated for a site. Further, to facilitate the electrical works, we obtained a special approval to take up tasks parallelly with the civil finishing activities to enable final completion. In terms of progress, we have completed 92.85% of works and are on track to deliver the project by February 2021.”

“Improvisation was key for our movement. To facilitate the electrical works, we obtained a special approval to take up tasks parallelly with the civil finishing activities to enable

final completion.”

P. Senthil Raja

Project Manager,

PAHW Substation Package 1148, Kuwait

Qatar was another front where a series of 132/11 kV substations were in line for commissioning with Project Manager, Gaurav Gaur’s at the helm of operations. “We were in the final leg of works when the partial lockdown restrictions were imposed which affected our supply chain as most of the equipment was sourced from Europe. A normal lead time of 30 to 45 days increased to 60 plus days but what worked for us was our virtual interface with the client for approvals which fast tracked the finalization process.” Factory Acceptance Test has been another significant digital breakthrough, acknowledges Gaurav, “Hopefully, this is one practise that will now become a regular in the new-normal saving time and cost.”

132 kV GIS HV testing at PAHW, Kuwait

“Our final hurdle was during the installation, testing and commissioning activities. The process required OEM supervision which was not possible hence we initiated several discussions with various project stakeholders to strategize and complete the works safely.” Gaurav and team have successfully energized all the substations between June and July reflecting a huge achievement for the team and one that has reaffirmed PT&D’s credentials as a premium EPC player in the transmission and distribution sector.

132 kV Al Daayen-2 – GIS

“Our final hurdle was during the installation, testing and commissioning activities. The process required OEM supervision which was not possible hence we initiated several discussions with various project stakeholders to strategize and complete the works safely.”

Gaurav Gaur’s

Project Manager,

132/11 kV Substations,Qatar

132/11 kV Mashaf-2 Substation

On an electrifying mission

The Saubhagya Cluster 1 project team led by Laxmi Narayana Mohanty has the onus of providing electricity connection to households in villages and replace LT overhead lines by AB cables across 06 districts. “Resumption of works meant that we had to specifically look at each district and chart a safe work plan following all the SOPs, considering the hotspots.” With the span running through rural areas, one of the team’s challenges was to communicate with the locals about their mission and safety objectives. Resuming with a meagre force of 103 workmen, they have gradually increased their strength to 900 by July.

“We are in the final leg of providing service connections to 1,69,258 households with 1,44,509 links established and 3664 km AB cable conversion work completed out of 5795 km by September.”

Laxmi Narayana Mohanty

Saubhagya Cluster 1 Project

“The site has achieved 30 km of cable laying in a single day which was not possible even before the lockdown,”

shares an extremely pleased Laxmi Narayana. With most of the major works accomplished, Laxmi Narayana and team are in the final leg of providing service connections to 1,69,258 households with 1,44,509 links established and 3664 km AB cable conversion work completed out of 5795 km by September.

AB cable laying at Saubhagya Project

Working out a modular approach

At the 220/110 kV MCMV Kochi Transmission line project, Project Manager, V. Chandrasekar adopted a modular approach to take up works that were at half-way stage. “Our span is close to 100 km and when the lockdown was announced we were amid some key tasks that could not be stopped immediately. With our client, KSEB’s support, we resumed works on 9th April and completed the activities and approached the district administration to procure approvals to commence works across all fronts on 17th April.” Starting with only 125 workmen, the team has gradually increased their strength to 350.

Stringing across a river at the 220/110 kV Kochi Transmission Line Project

“Being on the move is all about how you transform constraints into workable options,” shares Planning Engineer, Sivaraj, with a gleam in his eyes, “Take for instance our issue of sourcing aggregates which was possible only after May 20th as the quarries were closed. We convinced the client to approve sourcing from ready-mix concrete units close by as they had ready stock which enabled us to continue our works.” The team has been strictly following all the safety protocols regarding movement of workmen and looking after their wellbeing. “Our client’s ready acceptance of digital interface has been a big plus for us,” smiles Chandrasekar. “Today, all our material inspections, drawing submissions are only through the online mode.” With the project getting an extension up to 31st March 2021, Chandrasekar is confident of achieving their deliverables.

Tower erection at the 220/110 kV Kochi Transmission Line Project

“We resumed works on 9th April and completed the activities and approached the district administration to procure approvals to commence works across all fronts. Starting with only 125 workmen, we have gradually increased our strength to 350.”

V. Chandrasekar

Project Manager,

220/110 kV MCMV Kochi Transmission Line Project

A step ahead

The pandemic has opened new vistas of working and to remain firmly ahead of the competition, it is important to rethink work processes leveraging their digital tools which PT&D IC has been doing diligently in many ways across fronts. Truly, the ‘Columbus of L&T’ is a step ahead in the game of power play!