RAILWAYS PROJECTS FIND GREAT TRACTION DESPITE PANDEMIC-CREATED BLOCKS

Often size and scale are cited as deterrents to achieve quality but by winning L&T Construction’s Quality Award for 2020, the challenging INR 3000+ Crore JICA funded Dhaka Metro project has proved yet again that where there is a will, there is a way. Project Director, Sunil Khattar’s mandate is for a Systems Project including Track, OHE, CBTC Signaling and much more, awarded to a joint venture of Marubeni Corporation and L&T in June 2018. It involves the development of Systems Works for MRT line 6 – 18.9 km stretch with 16 stations.

The brief scope of work involves procurement of E&M systems comprising Track Works, Electrification Systems (Power Supply, Catenary, SCADA, and Energy Storage System), Lifts and Escalators, Signalling, Telecommunication & Automatic Fare Collection Systems and Platform Screen Doors for MRT Line 6 divided into the Uttara North Depot to Agargaon and the Agargaon to Motijheel phases. “Our work commenced on July 11th, 2018 and we have been mandated to complete the two phases in 1155 and 1519 days respectively,” Sunil points out although his progress was halted for a few days in March 2020 and thereafter ran at only half steam till September.

“The project team listed out materials required at site under each sub-system, tabulated their present status, developed strategy, implemented measures to mitigate the delays and prevent deterioration of material for each sub-system item. This also helped us to build substantiating data for future claims.”

Sunil Khattar

Project Director, Dhaka Metro Project

The Dhaka Metro team takes advantage of the lockdown

Of the 3Ms, Material was Planning Manager, Debakash Banerjee’s key concern who could ill afford the loss of even a day facing some stringent delivery deadlines. “While physical activity stopped at site, we continued to coordinate with our global suppliers to ensure that they remained committed to their manufacturing and shipping schedules,” he says purposefully. The Bangladesh Government stepped in to ease the situation by allowing e-filing of import permits and clearing customs to facilitate imports. “It was touch and go but finally the material successfully arrived at our stores safe and sound,” Debakash Banerjee’s relief is evident.

The Employer – Dhaka Mass Transit Company Limited and the Engineer (Nippon Koei – DMRC – Mott MacDonald) were constantly in the loop on every development be it delays in manufacturing, shipments or port clearances, “for which,” Sunil elaborates, “the project team listed out materials required at site under each sub-system, tabulated their present status, developed strategy, implemented measures to mitigate the delays and prevent deterioration of material for each sub-system item. This also helped us to build substantiating data for future claims,” he says with a half-smile. To keep their installed assets, site offices and stores safe during this period of uncertainly, the requisite security arrangements were made including offering incentives and medical facilities to the security staff.

Viaduct OCS wiring

Restarting operations with all precautions

Operations resumed to the new normal for which SOPs were finalized and circulated to all the staff and key stakeholders including the Employer, Engineer, the JV partner, and the L&T employees that stipulated the various COVID-19 safety protocols.

For the safety of the workmen, four new labour colonies were put up equipped with the requisite facilities, toilets, washrooms, and kitchen. They were provided temporary alternate accommodation till the new facilities were ready. The HR and admin teams, meanwhile, got cracking by reaching out telephonically to the local labour urging them to re-join by offering incentives like accommodation, food, testing and medical facilities. “The Employer supported us in this counselling activity,” Sunil chips in. All site personnel were PCR-tested and those positive, quarantined and put under continuous doctor’s monitoring. It was easier to restart work as none opted to return to India by the evacuation flights.

Phase 2 works: outside stabling shed

The team’s aggressive follow-ups with global suppliers translated into a slew of material from across the world landing safely at site from April to July to sustain progress. These included Rectifier Transformers from TMC, Italy, Copper Conductors from Lamifil Belgium, Escalators from OTIS, China & Master Clock System from Mobatime, Switzerland. In addition, several deliveries arrived from across the border from India including Circular Masts from Valmont, 132 kV Cables from Universal Cables, 33 kV Switchgear from SIEMENS, SCADA Systems from ABB and Telephone Systems from Alcatel Lucent.

Even as businesses started to adopt and adapt to the new ways of digital interface, Factory Acceptance Tests rapidly gained acceptance and the team organized FATs for various signalling items like CBTC wayside equipment, ATS server and Network SW rack; Automatic Fare Collection System equipment like passenger gates and Platform Screen Doors with internal units.

Masts for DC Overhead Catenary System

By successfully returning to full steam in 100 days, the team won the Engineer’s support who granted an extension of 66 days for the delay and reimbursed their claims for the PCR tests conducted and for constructing the new labour colonies, commending the team for their efforts for holding their stations to overcome the adverse impact of the pandemic.

Both the Engineer and Sunil are delighted that the project team has completed some major physical works for Track Works (plinth construction and track linking), Overhead Catenary System (OCS) works and receiving & traction sub-station works.

Core EPC 7 project back on rails

‘Mission Electrification’ is a Government of India initiative to electrify the entire Indian Railway Network to reduce both the carbon footprint and the expenditure on diesel. The Central Organisation for Railway Electrification (CORE), an engineering wing of railways, has been assigned this task of electrification. Amidst tough competition, L&T’s Railways SBG won the EPC project in early 2020, tasked to electrify the Dindigul- Palghat (Gr. 273), Pollachi-Podanur (Gr. 274) and Shoranur-Nilambur (Gr. 275) sections. The scope encompasses OHE, building eight Traction Substations, 57 SP/SSP, modification of HT/LT power lines and crossings, extending the LT Power supply for CLS work, Signalling & Telecommunication System modifications & inventory, integrated testing and commissioning, civil engineering works, height gauge works, service buildings, PSI depot, 2126 m platform shelter modifications, protective screens, completing tower wagon shed including siding, etc., P-Way works and the plantation of trees.

For Chief Project Manager, Venkatesh M Nagabhushan, the contract commenced in June 2020 and with the pandemic still around, he and his team focused on pushing forward with mobilizations. “Without wasting any time, we prepared, submitted and finalized contractual submittals with the Client like drawings, work programmes, lists and formats for execution and quality checks,” he informs. Under the leadership of Cluster head Akula S Phanendra Kumar, the team finalized and mobilized specialized equipment through online discussions with the HQ team and vendors, identified and mobilized the requisite staff, mobilized workmen for initial works from within Tamil Nadu as the movement from other States was restricted and completed project scheduling and planning using TILOS (Linear networking program) to arrive at an effective execution strategy.

“Without wasting any time, we prepared, submitted and finalized contractual submittals with the Client like drawings, work programmes, lists and formats for execution and quality checks.”

Venkatesh M Nagabhushan

Chief Project Manager, EPC Project

Action from word “go”

“We got to work from Day One itself, but we faced three primary concerns: the scarcity of workmen in Tamil Nadu, difficulty in remobilizing labour due to the travel restrictions and a rocky, unapproachable terrain at site.” Venkatesh describes his challenges, but not ones to be deterred, he and team set about pushing progress. Design modifications were finalized in a focused manner right at the initial stages itself to create design-based work-fronts to avoid any labour idling. “In terms of the terrain, we divided it into three: normal soil, normal soil but with high bank and rock strata, and then deployed the necessary resources accordingly to increase productivity.” The team could only mobilize labour from outside Tamil Nadu by September after which progress has been much faster.

Work began in right earnest with the OHE foundation works by engaging local agencies working with the limited relaxation given by the Tamil Nadu Government in various districts and, in the process, the team completed more than 10,000 foundations – a record in the history of the Indian Railways.

Several reasons for success

Communication, Venkatesh flags off, as one of the primary reasons for his team’s success. “I directly communicate with the customer for all actions, decisions, and approvals and close co-ordination with other departments such as planning, execution, and procurement has speeded progress.”

“Close monitoring of site productivity, effective utilization of resources and exceptional strategic methodology have been other reasons for our great performance,” ASPK grins.

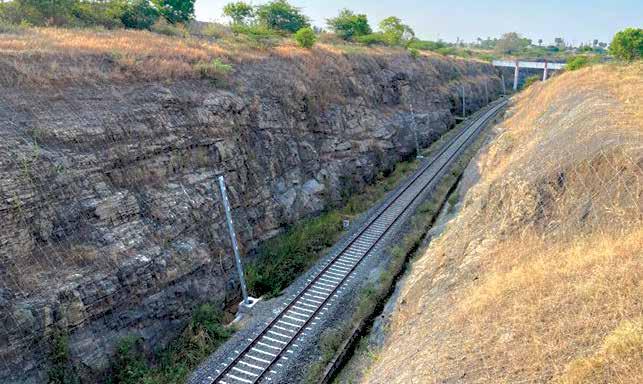

Accessibility challenges owing to Single Line at many sections and passing through hard, rocky strata

Shouldering the responsibility for the complete electrification of 215 TKM of Gr 272 (Salem-Vridachalam-Cuddalore Port) Section which includes 1 TSS and 10 SP/SSP is Pawan Verma, Project Manager for Package 1. Working with intensity, within a short span of 276 days, Pawan and his team successfully completed the CRS Inspection of the 59 TKM Cuddalore Port Junction – Vriddhachalam, the first block section of CORE EPC 7 Project and the team is gunning to complete this job by October 2nd, 2021.

Electrification works stretching more than 600 TKM were also kicked off despite the challenges of lack of labour, movement restrictions and poor utilization of vehicles and P&M. Project Manager for Package 3, Chandan Kumar tasked to electrify 326 TKM of Gr 273, Gr 274 and Gr 275 which includes 3 TSS and 16 SP/SSP had to contend with a hard, rocky strata and heavy rains initially. “With an efficient strategy and proper resource utilization, we have completed over 2,400 foundations,” says a pleased Chandan, who is confident of commissioning his section in the next couple of months.

“With an efficient strategy and proper resource utilization, we have completed over 2,400 foundations.”

Chandan Kumar

Project Manager, Package 3

Looking at the impressive progress the team has made, Venkatesh sums up what has worked for them. “Quick mobilization of manpower, equipment & material, implementation of First Time right principles to avoid rework, close follow-ups with the government authorities for statutory permissions and effective execution based on a clear strategy using TILOS, have been our key enablers,” he says, already ready to leap into his next MS Teams meeting.