RREC PROJECTS MAKE SIGNIFICANT HEADWAY DESPITE CHALLENGES

The revival of two mega RREC projects, the Mumbai Nagpur Expressway and the Madhya Pradesh Expressway are akin to a car speeding in top gear, suddenly forced to brake to a halt and then gradually regaining momentum. Immediately on receipt of their respective NTPs, both projects roared off their starting lines, initially making impressive progress only for the pandemic to bring them to a grinding halt before picking themselves up to continue the race to deliver ahead of time.

MNEP – all about pre-planning, coordinating & earth moving

RREC’s Road & Bridges BU is busy constructing Package no. 10 of the super communication Mumbai Nagpur Expressway project, also known as the Hindu Hridhay Samrat Balasaheb Thackeray Samruddhi Mahamarg, considered one of Maharashtra’s most prestigious and pivotal projects connecting the major cities of Mumbai & Nagpur. RREC’s scope involves 58 km of 6 lane rigid pavement with 151 structures including 83 culverts, 4 major bridges, 19 vehicular underpasses, 20 light vehicular underpasses, 14 minor bridges, one vehicular overpass, 9 canal bridges, 3 interchanges and a railway over bridge.

Even before construction began, the team pre-planned and diligently completed critical pre-construction activities like removing encumbrances, shifting utilities, and cutting trees. The team had to handle an enormous quantity of earthwork of some 1.77 Crore cum that called for precise planning and systematic execution to proceed unhindered, according to Project Director, Srinivas Rongali. “The alignment of the road passes through extremely undulated topography which is why so much earthwork was involved but we achieved it all very well,” he smiles with satisfaction. Another tricky matter to handle was to manage the remote hamlets that spread from Surala to Fatiyabad villages in Maharashtra’s Aurangabad district through which the alignment passes. “This also called for tactful handling that we have managed without too many issues.”

“Several times it is quick and decisive decisions that has stood us in good stead to rapidly remobilize manpower, obtain statutory permissions from Government authorities, maintain continuity in supply chain operations, retain skilled workmen, resolve local issues, eliminate local disturbances, maintain good relations with the authorities and the consultant to deliver.”

Srinivas Rongali

Project Director, Mumbai-Nagpur Expressway

Parallel processing

As the team progressed with the earthwork, they parallelly ensured the crushing of aggregates that was totally to the extent of some 29.11 lacs. “We were thus assured of adequate quantities of aggregates well in advance that helped us accelerate our execution,” points out Planning Manager, Abhinav Agarwal. “Further, by installing crushers in a remote area and operating them efficiently, we achieved our crushing and transportation targets.” Srinivas is all praise for the EDRC team for procuring all the design and drawing approvals from the Authority Engineer well in time to help the project make quick ground. “Subsequently all the statuary approvals were arranged in a time bound manner from the local administration freeing the execution team to focus on completing the planned tasks.”

They achieved their first and second milestones ahead of schedule and were moving ahead in full throttle when the pandemic struck, not once but in two waves.

“Despite all the challenges, we continued our operations, especially supply chain and subcontracting, that has helped us maintain project performance.”

Abhinav Agarwal

Planning Manager, Mumbai-Nagpur Expressway

An uphill struggle

The challenges were several: labour migration, remobilization, workmen retention, supply chain disruptions, threat of infections and, at the same time, push progress. “Be strong now, it might be stormy now, but it cannot rain forever, and things will get better sooner rather than later,” was Srinivas’s rallying call to his team. “In the given scenario, the team has done their best and although progress slowed considerably, we stuck to our stations that helped when the situation began to improve,” he says, seriously. Remobilization has been on a massive scale and the administration team has played a crucial role to ensure that both staff and workmen have remained relatively free from infections.

Girder erection for Rail Over-Bridge in progress at Mumbai Nagpur Expressway

For uninterrupted progress, all instructions from the government were strictly followed, all required permissions procured and all statutory compliances adhered to. A major triumph for Abhinav was to maintain the project’s cash flow. “Despite all the challenges, we continued our operations, especially supply chain and subcontracting, that has helped us maintain project performance,” he says. Apart from keeping the workmen motivated and, in the mood, to work, M K Pradhan and his team ensured that all the P&M were in good shape and functioning well while the execution led by Injeti Rajasekhar and Vikrant Joshi focused on completing the project ahead of time, whatever it takes.

Against this backdrop, the team, and the Safety In-charge are cheerful that the site has won the British Safety Council’s Safety Award 2020 and a RoSPA Gold to boot.

Srinivas acknowledges that managing unplanned issues to keep the ball rolling has been the big task for his team. “Several times it is quick and decisive decisions that has stood us in good stead,” he says, “to rapidly remobilize manpower, obtain statutory permissions from Government authorities, maintain continuity in supply chain operations, retain skilled workmen, resolve local issues, eliminate local disturbances, maintain good relations with the authorities and the consultant to deliver.” A very tall order but Srinivas and his team are up to the challenge.

Making inroads at the MPE project

Of the new 8-lane, greenfield accesscontrolled Delhi-Mumbai expressway, RREC is executing Package 22 near Ratlam in Madhya Pradesh. The 25-km long alignment with perpetual flexible pavement involves the construction of 4 major bridges, 29 minor bridges, 48 culverts, 15 underpasses, 1 ROB, 1 overpass, two interchanges and a toll plaza complex. A rocky hill, a km long and 35 m high, splits the project into two parts and the team was left with no alternative but to cut through the hill instead of traveling 40 km around it to reach Ratlam. It poses challenges for the planning of logistics and camps and involves 16 lakh cum of hard rock cutting in six months. Project Director, Jeeva David was not breathing easy to begin with because as he says, “Forest permissions, permissions to cut trees, utility approvals were pending and only 45% land was available, but we began right on cue on November 20th, 2020, when the project was awarded.” While Project Manager, Anil Kumar Sachan, Admin & IR In-charge, Rajiv Kumar and Planning In-charge, Dhananjaya N V set about obtaining all the statutory permits, Highway In-charge, T Suresh, and his team played a vital role to ensure that 90% of the land was available in quick time.

Subhashis Rout & his team from Quarry and Crusher established all the crushers at the foot of the hill and aggregate production commenced from November 2020 hugely saving cost and time. Within a month, a temporary ramp enabled easy movement of machinery and materials. The plant mobilization process began in July 2020 and was quickly operationalized by the P&M Team led by Sagar Majjilya, ensuring that concrete was poured from the first day itself. All plants have EB connections instead of DGs to be cost effective from word go.

“We created history by laying 15,000 MT asphalt continuously for 69 hours, created a record by laying 5000 MT WMM in a single day, crushed 17,000 MT aggregates/ GSB in a single day, achieved our first milestone in 87 days, i.e.168 days ahead of schedule and the second in 222 days, 218 days ahead of schedule.”

Jeeva David

Project Director, MPE project

The EDRC team ensured that all drawings were available in time while the QA/QC team led by Kishore Kumar Bellam ensured that all source approvals and design mixes were in place on time, using 100% crusher sand instead of river sand to substantially reduce cost. Structure and Highway teams with Chandan Kumar Upadhyay, Ashok Kumar Misra, Biplab Kumar Ghosh & Konetirao Chakrapani V and others pushed the pedal and have several successes to share. Jeeva holds forth with the numbers. “We created history by laying 15,000 MT asphalt continuously for 69 hours, created a record by laying 5000 MT WMM in a single day, crushed 17,000 MT aggregates/GSB in a single day, achieved our first milestone in 87 days, i.e.168 days ahead of schedule and the second in 222 days, 218 days ahead of schedule.”

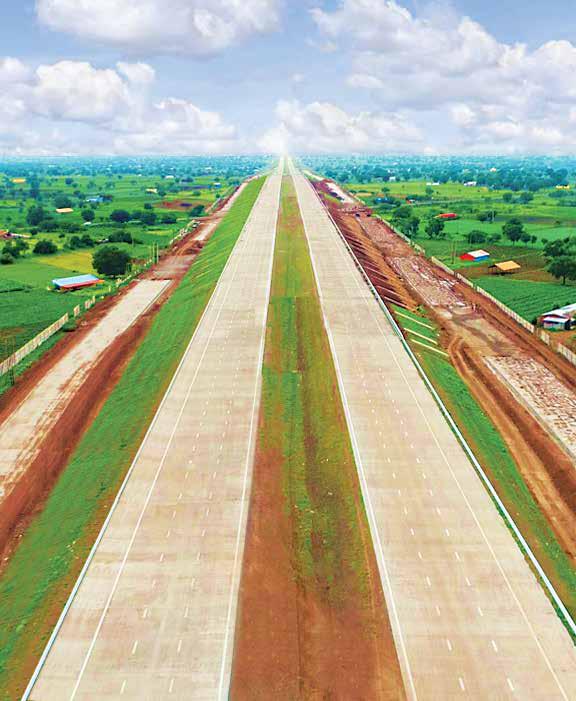

Asphalt laying in progress at MP Expressway

The pandemic halted their progress and despite the sterling efforts of the F&A team under Bimal Kanti Roy, 40% of the staff and some workmen tested positive.

Three months of the Government’s COVID-19 restrictions hampered progress, but the team still achieved their Milestone-2 of 35% of invoice, a good 218 days ahead of the contractual date. Jeeva agrees that several things like quickly mobilising workmen from other States even when the restrictions were on, closely following up for the maintenance of equipment, efficient procurement of material and conducting all meetings regularly and virtually helped to keep progress robust. “Obtaining the statutory permissions from the Government authorities, maintaining good relations with the authorities and consultant while adhering to our professional commitments really gave us a good lead over time,” he concludes.

Girder erection for a major bridge in progress at MP Expressway

CTP-14 regains momentum

Being a focal point in the WDFC stretch, the 128-km Rewari-Dadri alignment Project CTP-14 is of strategic relevance and the site was in high gear doing 86K cum concrete, 17.15K cum of embankment laid in Jan-Mar 21 and had commenced the NTC track linking for the Prithla-Asaoti connection in March when the second wave struck disastrously taking in its wake some of our colleagues. Picking up the threads, Project Director, Manish Samtani along with his Project Manager & Head – Structures and Formations, Jey Kumar and Administration Head, C.S. Rao, formed a COVID task force to address the immediate issues of treatment and succour. “We had to close the site for two consecutive weeks due to rising cases,” shares Manish, “but the team utilized the break to make reconciliations, prepare catch-up plans, conduct online training on quality, crushers, and management subjects by the Project Department Heads.” On restart, stringent COVID testing, a special Bubble System and vaccinations kept infections in check.

When work began in May 2021, the team hit the board running achieving an average concrete of 30K per month, handing over 220 structures to the formation team for backfilling and another 100 structures in the Prithla – Faridabad section, out of the total scope of 107, to make way for Blanket and Ballast laying for NTC movement. When concrete works ground to a halt, the workmen left reducing their original strength of 1,500. However, with all-out efforts, labor strength increased to 1250 levels to take up the balance 1.4 lakh cum. of concrete, 60 K cum. of which has been completed till date. “A breakthrough was getting the KMP diversion, that is critical for project commissioning ready by June-21,” enthuses Jey Kumar. “In fact, this diversion was commissioned soon after

re-mobilization.”

PRIOR TO THE SECOND WAVE, THE TEAM HAD DONE 13K MT OF CRUSHING, 14K MT OF BOULDERS, 15 LMT OF BLANKET PRODUCTION, PROGRESSING TO COMPLETE THE CH 91+542 TO CH 104+000 STRETCH.

Girder erection for a viaduct in progress at DFCC CTP14

Road diversion for structure works at DFCC CTP14

The Formation works had to face serious issues too ranging from NGT Ban to non-availability of borrow earth due to the season, to statuary changes in NCR and the farmers’ protest. Under the leadership of Priyang Panchal, the team worked round the clock to meet the Employer’s expectations. Prior to the second wave, the team had done 13K MT of crushing, 14K MT of boulders, 15 LMT of blanket production, rogressing to complete the CH 91+542 to CH 104+000 stretch.

“We successfully completed all formation and structural activities of CH 91+542 to CH 104+000 and are forging ahead with the earthwork, earth retaining structure and the crucial blanket works despite the onset of the monsoon.”

Priyang Panchal

Project Control Head, DFCC – CTP 14

After the resumption of work, despite struggling with labour shortage and heavy rainfall in NCR, the team achieved the highest blanket production of 1.7LMT in July 21. In Quarry and Crusher activities, the team reached 10K MT of crushing daily. “We successfully completed all formation and structural activities of CH 91+542 to CH 104+000 and are forging ahead with the earthwork, earth retaining structure and the crucial blanket works despite the onset of the monsoon,” points out Priyang.

“In the eight months between the two waves, we have had to face the monsoon season and NGT ban that affected us for six weeks, yet we achieved 100% against the targeted progress and invoice,” says Jey Kumar, happily. “The team has resettled, is well organised in terms of resources and is on target to complete formations and structures by March 2022,” he concludes on a positive note.