TWO ICONIC L&T GEOSTRUCTURE PROJECTS MAKE SIGNIFICANT PROGRESS IN WEST BENGAL

For a specialized business that relies so heavily on skilled manpower and specialized equipment, one can only imagine the disruptions caused by the COVID waves to projects of L&T GeoStructure. Yet, the site leadership and hardy teams of two iconic projects have weathered the odds to record substantial progress.

Bank protection work plays a pivotal role in river training works, and there are various purposes for bank protection:

i. Training of the river

ii. Protecting the adjacent lands and valuable properties threatened by river erosion

iii. Protecting the hydraulic structures against the direction and nature of the current

iv. Protecting the flood embankment v. Creating facilities for water transportation

FLOOD PROTECTION WORKS, KOLKATA

FOR A FLOOD-FREE LIFE

The West Bengal Major Irrigation and Flood Management Project being executed by L&T GeoStructure for the Government of West Bengal Irrigation and Waterways Department aims to improve the quality of lives and save property of people living along the banks of the Hooghly River whose lives are frequently impacted by cyclical flooding. Spanning a total length of 122.44 kilometers, Project Director Kanchan Patra’s scope is divided into four packages that are at varying stages of completion. “Handing over of the project in a phased manner starts from March 2022, for which our immediate objective is to drive sheet piles in the remaining scope and complete the slope pitching works,” he informs. “We have completed 71% of Package 1, 43% of Package 2, and 33% of Packages 3 and 4.

“Handing over of the project in a phased manner starts from March 2022, for which our immediate objective is to drive sheet piles in the remaining scope and complete the slope pitching works. We have completed 71% of Package 1, 43% of Package 2, and 33% of Packages 3 and 4.”

Kanchan Patra

Project Director,

West Bengal Major Irrigation and

Flood Management Project

DESIGNED AND BEING EXECUTED IN THREE MAJOR PHASES

During phase one, the task is to drive sheet piles below the Hydraulic Gradient Line (HGL) along the embankment to prevent seepage of flood water. 71 km of this work has been completed till date. The second phase involves constructing flood walls along the embankment to prevent the water from spilling over during flood situations “We have completed 22.87 kilometers of flood walls and 5.93 kilometers of capping beams,” updates Package 1 Project Manager Vinod Bapurao Thakare. The third phase is about protecting the embankment slopes by pitching the slopes with Laterite boulders and other suitable materials. “These three phases combined will strengthen the embankment and make it durable to withstand floods,” Vinod adds. “We have completed 73,000 cum of concreting, which constitutes 50% of the total concreting as per our original scope.”

“We have completed 22.87 kilometers of flood walls and 5.93 kilometers of capping beams. We have completed 73,000 cum of concreting, which constitutes 50% of the total concreting as per our original scope.”

Vinod Bapurao Thakare

Project Manager,

West Bengal Major Irrigation and

Flood Management Project

DIGITALIZATION PLAYING A CRUCIAL ROLE

Drones were extensively used initially for the survey to gather topographical data and are continuing to be used effectively to monitor project progress, identify obstacles or hindrances, and alert the team of changes in geographical features. “We are extensively using the WISA application to mobilize workmen with the necessary skillset so that the right people are selected to do the right job at right the time,” points out QA/QC Head Shreekant Kumar, “and it came in most handy when we had to re-mobilize workmen after the easing of restrictions.” The IB4U application is regularly used to inspect plant, machinery, and equipment, and to gauge their overall fitness. The Asset Insight application streams information about diesel consumption, HMR readings, and the like, while transit mixers and tractors are GPS-tracked to ascertain their routes and ensure that the shortest possible route is being taken to maximize productivity. “Our execution is certainly more agile after going digital,” observes Construction Manager Nowshath Hussain, “and has significantly saved us a lot of time by synchronizing the different departments involved in decision making.”

“We are extensively using the WISA application to mobilize workmen with the necessary skillset so that the right people are selected to do the right job at right the time and it came in most handy when we had to re-mobilize workmen after the easing of restrictions.”

Shreekant Kumar

QA/QC Head,

West Bengal Major Irrigation and

Flood Management Project

MAKING A STRONG STATEMENT TOWARDS SUSTAINABILITY

Even though the project is a significant ‘green’ initiative, the project team is mindful of maintaining the environmental balance in the local ecosystem. Thus far, they have planted 4,105 trees and conducted 120 environmental monitoring exercises. 2,940 people have been trained in 209 sessions spanning approximately 4,000 hours. The project team has also filed a nomination for the RoSPA safety international award. During the past year, the site witnessed three record flood situations. The entire site team implemented quick and effective preand post-flood protection measures, augmenting permanent works. The client spontaneously appreciated the exemplary leadership provided by L&T GeoStructure. The locals were happy too, realizing that the project is already yielding the desired results of

flood protection.

“Our execution is certainly more agile after going digital and has significantly saved us a lot of time by synchronizing the different departments involved in decision making.”

Nowshath Hussain

Construction Manager,

West Bengal Major Irrigation and

Flood Management Project

NAVIGATIONAL LOCK AT FARAKKA

AN IMPORTANT NATION-BUILDING PROJECT

The new Navigational Lock that L&T GeoStructure is constructing in Farakka, West Bengal, will raise and lower ships or vessels between stretches of water of different levels on the river and canal waterways to facilitate quicker and more efficient water transportation. The existing lock gate is old and inefficient and takes a vessel more than two hours to pass upstream or downstream. With the new lock, a vessel will be able to pass through in just 38 minutes, and if it is followed by the movement of another vessel in the opposite direction, the operating time will be only 23 minutes.

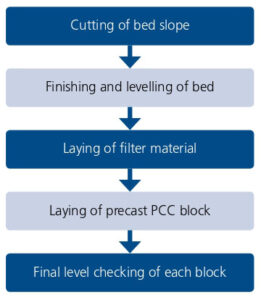

CONSTRUCTION SEQUENCE OF PPC BLOCK PITCHING

The scope of work includes constructing the lock structure (250 m long), the guide wall both upstream and downstream, fabricating and installing gates, bank protection works, control room building equipped with mechanical and electrical facilities to remotely operate the gates, road works and other ancillary works. “90% of our project is over,” states Project Manager Aruni Ranjan , “and our objectives for completion involve testing the lock and gates and dredging works.”

At Farakka, the bank protection work is being executed by the PCC precast block pitching method with the main intent to protect the soil bed from erosion. To circumvent the impulse of the water on the bed slope as it forcefully enters and exits the navigational lock, the block pitching is introduced both upstream and downstream.

“90% of our project is over and our objectives for completion involve testing the lock and gates and dredging works.”

Aruni Ranjan

Project Manager, Farakka Project

BED SLOPE PREPARATION

Excavation was done from top to bottom and blocks were laid from bottom to top in three bed slopes. “We faced several challenges during this process due to the changing strata of soil and water seepage due to high groundwater table level,” points out Planning Engineer Nunna Sameer Guptha. “We even encountered permeable silty sand strata over a certain depth in the middle of excavation profile resulting in soil collapses and issues of over-excavation.”

“We faced several challenges during this process due to the changing strata of soil and water seepage due to high groundwater table level. We even encountered permeable silty sand strata over a certain depth in the middle of excavation profile resulting in soil collapses and issues of over-excavation.”

Nunna Sameer Guptha

Planning Engineer, Farakka Project

To maintain the soil bed slope, overexcavated soil was used as backfill, but it proved unstable due to constant seepage of water. “We considered filling the over-excavated soil with external material like concrete and mortar, which helped to maintain the slope, but we found it to be impermeable as water was finding some way to seep through the bed surface, leading to soil collapse,” says QA/QC Head Raghu Raman with a shake of his head. “We, however, brainstormed and arrived at a suitable solution of using ‘Pervious Concrete’,” he smiles triumphantly.

“We considered filling the overexcavated soil with external material like concrete and mortar, which helped to maintain the slope, but we found it to be impermeable as water was finding some way to seep through the bed surface, leading to soil collapse. We, however, brainstormed and arrived at a suitable solution of using ‘Pervious Concrete.”

Raghu Raman

QA/QC Head, Farakka Project

WHAT IS ‘PERVIOUS CONCRETE’?

Pervious Concrete (also called porous concrete) is a special type of concrete with high porosity used for concrete applications that allows water from precipitation and other sources to pass directly through it, reducing the runoff from a site and allowing groundwater recharge. Pervious Concrete consists of cement, coarse aggregates, and water with little to no fine aggregates. The mixture resulted in a void content of 15 to 25 per cent. In its fresh plastic state, the concrete can be moulded according to the required slope on the bed surface.

By using Pervious Concrete at the collapsible locations to match the excavation profile of block pitching, further collapses were prevented by allowing the seepage water to easily drain through it via its voids, thereby strengthening the bed slope. “This measure not only enhanced the product quality but also proved to be an efficient measure to reduce the time cycle of block laying by weeding out the need for rework at such collapsible locations,” says Raghu.

SIGNIFICANT ACHIEVEMENTS

The project was awarded the Digital Trophy in 2018 for being the best digitally enabled site, much to Nunna’s delight, who is driving digitalization with gusto at site. “We use Procube, Quality Incident Reporting, and the Safety App and have installed GPS in diesel generators, cranes, and batching plants as a part of our drive towards a ‘Remote Monitoring Control System’.” Solar panels have also been installed at site to operate and monitor instruments like the data logger.