WET IC’S KALAHANDI PROJECT IS ODISHA’S FASTEST COMPLETED IRRIGATION PROJECT!

Not surprisingly, it has won the Timely Delivery Award too!

Completed on December 10th, 2020, WET IC’s Lift Canal System of the Upper Indravati Irrigation Project (UIIP) was inaugurated by the Hon’ble Chief Minister of Odisha, Shri Naveen Patnaik, and recognized as the fastest completed irrigation project in the State, certainly a matter of pride for Project Director S. Devanand and his team for whom more accolades were forthcoming, winning the coveted Timely Delivery Award of L&T Construction. “It is a matter of honour and pride to win this award,” says Devanand, accepting the award, but what must have been even more satisfying and fulfilling for him and his team is that their project will irrigate 25,275 Ha of high elevation land in 87 villages, benefiting 3 lakh farmers in the district. “We are extremely happy to have transformed one of the remotest and drought-prone districts of the country into the second largest rice production hub of the State,” he adds, his eyes shining.

The task for the project team

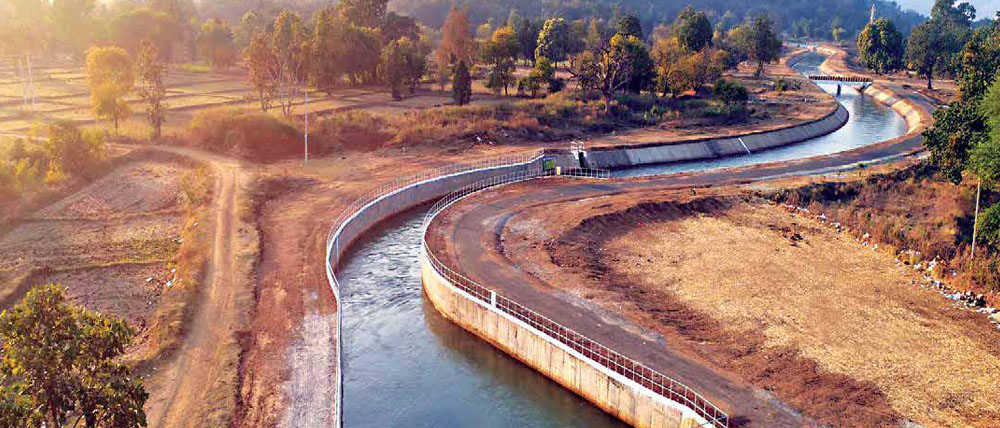

The project scope involved survey, land acquisition, design and execution of 7.1 km of 132 kV transmission lines, 132/6.9 kV switchyard, pumphouse-cum-forebay channel with 8 VT pumps and motors of 2,145 HP capacity, 8 rows of 4.6 km MS rising mains, delivery channels, 16 residential and non-residential buildings, 43.26 km CC-lined canal with 164 associate structures including 8 aqueducts, and 4 Ha Chak distribution network system of 1,142 km to cater water to 25,275 Ha of cultivable command area. The canal, transmission line, and distribution network are spread across 110 villages in four blocks of the Kalahandi district in this cross-country project.

Situated in the south-west region of Odisha, Kalahandi is one of the most backward and drought-prone areas of the State, with people primarily dependent on agriculture for their livelihood. Project work began in earnest on March 12th, 2015, and though the contractual completion date was March 11th, 2020, the actual working period was 25 months, as the entire system runs through agricultural fields, and the monsoon and cultivation restrictions in the area meant a limited working season of maximum five months a year. “We received a 9-month extension from the client due to delays in land acquisition apart from the disruptions due to the pandemic,” points out Planning Manager, S. Ragupathy.

132 kV transmission line

“All payments have been realized and collected including the final bill, and the system successfully operated and maintained for 12 months.”

S. Devanand

Project Director,

Upper Indravati Irrigation Project

The project was successfully completed and commissioned right on time. A satisfied client, for their part, promptly awarded the completion certificate; the project was then handed over for Operation & Maintenance (O&M). “All payments have been realized and collected including the final bill, and the system successfully operated and maintained for 12 months,” smiles a satisfied Devanand.

132/6.9 kV switchyard

“Success in our construction industry hinges on how well project teams are able to improve productivity, reduce wastage, costs, and rework, enhance efficiencies and thereby reduce execution time, which has been our primary objective at this site,” shares a delighted S Giridharan, Vice President & Head – Irrigation, Industrial Infrastructure (WET IC). “We look minutely at every aspect that can impact our delivery and this award is a true recognition of our success.”

Competency sought, and delivered

For WET IC, the project was a learning curve, being the first EPC canal project bagged by the business amid stiff competition; hence, to prove themselves, speed of delivery was of the essence. The team quickly realized that one of the biggest impediments to speedy execution of 1,142 km of distribution pipelines through agricultural lands would be the local population. Devanand’s first task therefore was to conduct various awareness campaigns and convene meetings with the district administration to educate the people about the benefits of this project. “We impressed upon them the importance of the project not only to improve their own lives but also for the overall development of their district. It was tough work, but slowly they came around to seeing things from our perspective,” he says grimly.

“Success in our construction industry hinges on how well project teams are able to improve productivity, reduce wastage, costs, and rework, enhance efficiencies and thereby reduce execution time, which has been our primary objective at this site. We look minutely at every aspect that can impact our delivery and this award is a true recognition of our success.”

S Giridharan

Vice President & Head – Irrigation,

Industrial Infrastructure (WET IC)

Land acquisition proved to be one of the biggest speed-breakers. However, Devanand, with his rich experience of similar cross-country pipe laying projects, identified at the very early stage of project execution the risks related to local disputes which would arise, and a dispute resolution team was constituted at site, client, district and State levels. This intra-level coordination helped the project team immensely, to proactively complete the most critical activity of acquiring 1,020 acres for the rising mains and canal alignment in 19 villages and procured the right of use (ROU) clearance to lay 1,200 km of distribution pipeline through agricultural lands with the support of the district administration, local government bodies and other beneficiaries. Simultaneously, Devanand envisioned the project’s end deliverables and divided the project into different reaches amongst Mr. Rajasekar S., Mr. Narayan Patra and Mr. Ananda Gangopadhyay, a decision that proved to be proactive.

MS pipe laying

A key contributor to the success of the project was the role played by the EDRC team. Apart from adopting a lean and economical design, they regularly visited the site to collect field data, sort out client concerns, provide on-site training to newly recruited design engineers and ensure that all quantities were within the tender/ACE scope.

“It was imperative to be always on top of things,” reminds Ragupathy, “and to quicken the design and drawing approvals at the Proof Engineering Consultant’s office, we deputed a design engineer and a draftsman in Bhubaneswar.”

Since this project was a first for EDRC too, the design of some crucial structures such as aqueducts and cross-drainages were outsourced to an external agency, though the valuable knowledge gained from the project should hold EDRC in good stead to design canals and canal structures going forward.

Delivery channel

The canal alignment was supposed to run through forest land, which would have created several complications, for as per the Environment and Forest Act, work cannot be taken up on forest or non-forest areas until the forest land acquisition is through, which usually took about a couple of years. “When faced with a mountain, go around it,” smiles Devanand, “for we overcame our problem by diverting the canal through an alternate alignment (even though the execution risk pertaining to deep excavations and new land acquisitions prevailed). We proceeded with that proposal, which not only avoided delays but also reduced the canal length by 1.74 km, further saving us time and cost.”

“It was imperative to be always on top of things and to quicken the design and drawing approvals at the Proof Engineering Consultant’s office, we deputed a design engineer and a draftsman in Bhubaneswar.”

S. Ragupathy

Planning Manager,

Upper Indravati Irrigation Project

Off the beaten track

Skilled labour is always an issue, and in such a remote corner of Odisha, it was even more severe, and the team’s only recourse was to identify, train and educate local workmen and subcontractors on a regular basis to execute the work as per L&T’s safety and quality standards. A total of 142 CWT and 148 SST programmes were organized, and 62 quality training sessions conducted, thanks to which the project received 16 Quality Appreciation Certificates from the client.

Pipe jointing & laying

Head regulator

Subcontracting posed another challenge, as the established L&T subcontractors refused to work on the project due to its remoteness, which, along with delays in land acquisition and frequent local interruptions, were threatening to derail progress. On a war footing, the project team identified and trained several local subcontractors. “Totally, we engaged 15 new subcontractors in headworks, 49 in canal works, and 31 in distribution network works,” informs Ragupathy, who adds that most of these newcomers are presently working at other WET IC project sites.

Canal lining

Time is money, and vice versa!

The project team’s strategy was aligned to execute the work at minimum operating cost by engaging local agencies and through continuous monitoring of site productivity. Several cost-saving initiatives ensured timely collection from the client to maintain a negative working capital and positive cash flow.

These initiatives significantly avoided delays, like eliminating the intermediate delivery channel, which saved costs in pumping head and operations. Supply and execution costs were saved by introducing uPVC pipes in the distribution network and reducing the number of residential and nonresidential buildings from 22 to 16 yet maintaining the total plinth area as per the contractual requirement and having double-storey buildings instead of the conventional single-storey ones. Precast valve chambers in the distribution network minimized execution cost yet ensured optimum product quality.

The operations team, involving Sudarshan Joshi and G. K. Roy, played their part by speedily mobilizing a huge pool of resources – 4 batching plants, 17 transit mixers, 4 self-loading concrete mixers, 50 excavators & dumpers, and 800 workmen – during the last working season.

Overcoming tall odds

Inevitably, work had to stop for 25 days due to the nationwide lockdown, but the team looked after their 800-strong workforce and 100 operators well, with the result that they were able to hit the board running once the team received special permission to resume works. “We poured 13,000 cum. of concrete in just 40 days after resuming work,” says Devanand proudly, tipping his hat to the site accounts & admin teams for providing all the necessary facilities to the workforce to operate 24×7 round the clock. “That helped us to complete the most critical deep-cutting stretch before the monsoon.” A total of 3.80 lakh cum. canal excavation, 1.67 lakh cum. canal banking, 24,000 cum. canal lining, and 11,000 cum. canal structure concrete was completed in double quick time during the peak of the pandemic outbreak.

Haste makes waste is a common adage and, at times, safety and quality can be compromised in the quest for speed. However, the sterling efforts of EHS Manager, Sujit Kumar Panda and Quality Manager, Raj Kishore Viswa Karma and their teams ensured that delivery was impeccable.

As responsible corporate citizens, the project team planted 49,746 saplings, organized seven blood donation camps to donate 364 units of blood and constructed eleven toilet blocks that were handed over to local schools. Apart from the canal providing water to the villagers for their daily needs and cattle, the approach road along the right bank of the canal constructed by the team is being regularly used by the villagers to commute.

Well-deserved praise and accolades

The Kalahandi project has received multiple awards over the years, including the Maximum Green Cover Award in H1 in both 2017–18 and 2018–19 and WET IC’s Quality and Timely Completion Trophies in 2020. The Timely Delivery Award is certainly the icing on the cake for the team, and richly deserved at that!