FOCUS ON ACTIONS, PREVENT INCIDENTS

A small proactive action can make a bigger impact than a ton of reactive measures. At L&T GeoStructure, we execute projects that involve ground improvement, piling work, and construction of dams, bridges, and other marine structures. Though the variety of work is less, risk levels are high, which can be dangerous if not addressed adequately. It is my pleasure to share a few of our proactively adopted technological solutions to eliminate risks and for better engineering control over the hazards we face.

Proactive safety initiatives

Using some simple engineering controls, we have efficiently controlled hazards in several areas of operation.

Contact with any moving, rotating, or energized part is one of the most serious safety concerns in batching plant operation, even though the primary controls are provided by the OEM. Major accidents still occur in areas like pan mixers and skip buckets. At the BHEL Ennore project site, we installed an automatic cut-off sensor in the skip bucket gate in addition to the manual locking mechanism for additional control. To prevent the lid of the pan mixer from falling onto maintenance personnel, we have installed a secondary locking mechanism in addition to the chain pulley lock provided by the OEM. On gantry cranes, an automatic functional alarm with anti-collision devices installed at the rail front ensures people safety and operational control in blind spots.

Working in the sub-structure during the rainy season is always a challenging job, as is moving and working with the massive equipment for piling and cut-off wall works that require more engineering control. At the COW Kanupur project, to address issues with the strata, our in-house experts developed an exclusive design involving a 500 mm-thick working platform comprising geotextile, crusher dust, GSB layer, geocell, and Wet Mix Macadam (WMM) constructed beside the guide wall, which prevented damage to the trackpad, improved stability, and enhanced the safety of the lifting operation.

Similarly, in our RORO project in KPL, we faced a different issue during the excavation work near the sea, where we are doing a 100 running meter long and 2 m deep retaining wall. When the area was excavated, we discovered that our sloping was not strong enough to hold the huge boulders we encountered. Our answer was to lay a catchment net throughout the length, which not only arrested the fall of boulders but also reduced the need for further excavation, thereby avoiding water ingress into the work area.

Proactive measures to preserve the environment

At the BHEL Ennore project, by saving almost 2,449.10 MW of power, we reduced emissions to the tune of 2,228.69 MT of CO2 with technological support and certain engineering alterations like installing Variable Voltage Frequency Drives (VVFDs) in three gantry cranes to optimize and reduce power consumption by almost 60%, transparent roofed office corridors and warehouses to harvest direct sunlight and avoid the use of electric lights during daytime, and energy-saving LED bulbs instead of HPSV lamps for all site lighting. These energy-saving initiatives cost us about ₹23.6 lakhs but reduced our cost of electricity by ₹3.13 crores, fetching us a clean profit of ₹2.89 crores and counting!

In our Katni Grade Separator and COW Kanupur projects, aerobic decomposers installed in the workmen habitat convert about 80 kgs of food and organic wastes generated every day into useful fertilizers that are used to develop green belt areas and, at the same time, address the waste disposal and sanitation issues at these sites.

Key proactive health initiatives

Grinding RCC walls always kicks up a lot of dust, which can cause severe and chronic health hazards to workmen, especially in a closed basement area. We successfully addressed this hazard at our IndusInd Bank project by replacing the conventional grinding machine with a vacuum-attached one to collect dust from the source itself.

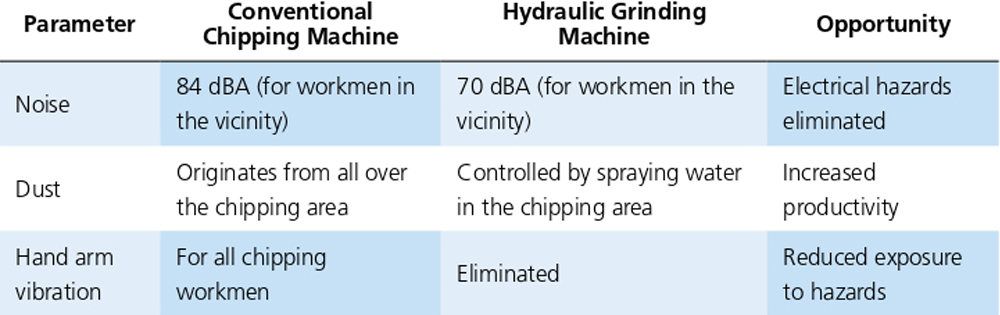

At our RORO Berth PL Project, we are constructing a diaphragm wall of 405 m length, 1.2 m thickness, and 40 m depth and 280 BCIS piles of 1.2 m diameter and 28 m depth for foundation. In our work, we need to chip off the top 1.5 m of concrete of the diaphragm wall and the top 2.6 m of concrete of the pile to place the precast structure and cast the

in-situ structure, respectively. This calls for chipping approximately 1,845 cum. of M40 concrete in a short period to meet the project schedule. Though the initial plan was to engage 30 chipping machines and jack hammers in a single location, which would have created a huge amount of noise and dust, with precast erection and concreting works occurring simultaneously, we have instead deployed an equipment-mounted hydraulic grinding tool in place of the conventional manual jack hammer, with several advantages.

Conclusion

Actions speak louder than words. Controls identified and implemented by one project team should be sincerely adopted by other project sites as best practices and imbibed into our EHS Management System. At L&T GeoStructure, we always adopt a holistic approach, encouraging new ideas and innovative thinking, to deliver excellent results. The support extended and the engagement of different department staff and workmen have played a significant role in establishing these initiatives, making them proud co-owners of these improvements. With the positive participation and involvement of our employees and workmen, action to ’Prevent Incidents’ will become a culture and a core value for us.