CHANGING THE WAY AN ENTIRE NATION COMMUTES.

MAURITIUS METRO PROJECT

On July 31st, 2017, in the august presence of the Honorable Prime Minister of Mauritius, Mr. Pravind Kumar Jugnauth, Larsen & Toubro was mandated by the Metro Express Limited to construct an Integrated Light Rail-based Urban Transit System in the island nation of Mauritius. Fully funded through a Government of India grant and Line of Credit, the project was bringing rail transport back to the island after 50 years, making this India-Mauritius flagship venture one of its kind in the Indian Ocean and the East African region. For L&T, it was an opportunity to spread its influence

into Africa.

Work started in earnest and two years later, on October 3rd, 2019, abiding to contractual obligations, Phase 1 wase-inaugurated by the Hon’ble Prime Ministers of India and Mauritius, opening for the Mauritian public a 13-km stretch from the capital, Port Louis to Rose-Hill, that included a sprawling Depot at Richelieu.

Today, 29.3 km of metro rail, with over 4.6 km of elevated viaducts and 7 bridges, connects all the towns of Mauritius to Port-Louis, carrying 35,000 – 40,000 Mauritians daily. Total passenger trips from 2019 to January 2023 have crossed 13.5 lakhs. Surely, L&T has changed the way a nation commutes.

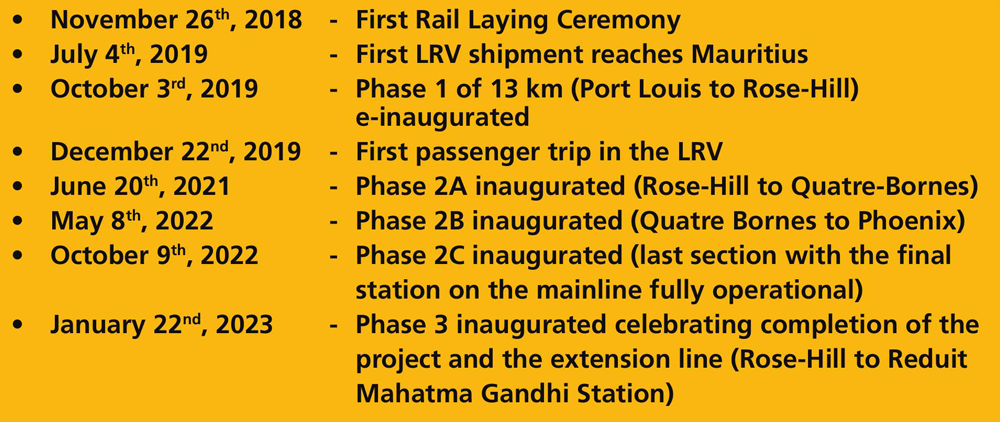

SPEEDY MILESTONES

“The Mauritius Light Rail Transit system, a track-to-train project, is a new, comfortable, timely, safe, and ‘green’ commuting experience with state-of-the-art infrastructure and facilities, and a triumph of L&T’s project management and execution capabilities,” says a visibly proud Project Director, Sanjeev Gupta. “Although we had to overcome some stern challenges, we have delivered a world-class project, clocking more than 24 million safe manhours in the process, developing nearly 500 local suppliers and directly employing 300+ locals for the operation and maintenance scopes.”

“Although we had to overcome some stern challenges, we have delivered a worldclass project, clocking more than 24 million safe manhours in the process, developing nearly 500 local suppliers and directly employing 300+ locals for the operation and maintenance scopes.”

Sanjeev Gupta

Project Director

Clearing the political air

A speck in the Indian Ocean, just 65 km long & 45 km wide, Mauritius is culturally diverse, with a democratic feedback system and a strong & strident media. Metro construction by its nature disrupts lives and in the early days, loud voices of protest were raised against movement restrictions, inconveniences to citizens, loss of property that threatened to derail the project. “After analyzing the reportage, we realized that much of the negativism was targeted at the project that people were unable to envisage, and not against L&T,” recalls Communications Manager, Nausheen Allybux. Effective and regular communication and public relations campaigns successfully influenced positive opinions and impressions amongst the citizens and stakeholders towards the project. Setting up a project office in Port Louis, engaging local suppliers & sub-contractors, hiring local talent, helped L&T to successfully integrate into the Mauritian psyche. “Soon, L&T was considered one of their own,” chuckles Rajeev Jyoti, then leading the project, “and as people started to understand the project and how it could be beneficial for them, the tide turned and from then on it was fairly smooth riding.”

“Soon, L&T was considered one of their own, and as people started to understand the project and how it could be beneficial for them, the tide turned and from then on it was fairly smooth riding.”

Rajeev Jyoti

Advisor to the IC Head, Transportation Infrastructure

A FEW TECHNICAL MILESTONES OF NOTE

- LRT 63.36 Tkm

- 1,181 OHL Mast

- 4,600 Rm Bridge & Flyover

- 23 Stations

- 12 Traction Power Substations

- 27 Rail/Road Intersections

Overcoming situational challenges

Cracking the COVID code: The pandemic with its resultant lockdowns, protocols, and restrictions completely disrupted lives and project progress for nearly two years. Thanks to the excellent relations with the local government and the health authorities, L&T’s employees and workers were given priority to get vaccinated and obtain work permits. “Acknowledging these favors, we swiftly and strictly implemented the COVID-19 measures and protocols within the labor colony and project office,” shares Head – Project Control, Pankaj Lamyan, “that prepared us to hit the board running even during the partial lockdown.”

“We swiftly and strictly implemented the COVID-19 measures and protocols within the labor colony and project office that prepared us to hit the board running even during the partial lockdown.”

Pankaj Lamyan

Head – Project Contro

Procurement challenges: Procuring materials, tools, and consumables related to Metro & Railway projects was a huge challenge for the team, executing on an island with no presence of Railway or Metro. Local labour oriented to metro construction was non-existent and there were very few local vendors to support the cause. “Since there were no manufacturing facilities exclusively for railway and metro components, we were largely depending on imports,” says Project Manager (Civil), Subhendu Ghosh, with a worried frown. No sooner was the world emerging from the pandemic induced disruptions that the geo-political tensions caused by Russia’s invasion of Ukraine in 2022 disrupted global trade & shipments and sent petroleum commodity prices soaring. “With meticulous planning and continuous follow-up, we developed local vendors, created a vendor pool, and maintained excellent relationships with all stakeholders to deliver on schedule,” remarks a relieved yet contended Subhendu.

“Since there were no manufacturing facilities exclusively for railway and metro components, we were largely depending on imports. With meticulous planning and continuous follow-up, we developed local vendors, created a vendor pool, and maintained excellent relationships with all stakeholders to deliver on schedule.”

Subhendu Ghosh

Project Manager (Civil)

Labour pains: Mobilizing workers from India to Mauritius was a tough nut to crack due to the stringent Government policies. The long-winded process involved a workman undergoing the prescribed medical tests in India, forwarding the original test reports to the Mauritius Ministry of Health for medical clearance certificates for employment, to prepare the contract of employment for approval from the migrant workmen section and apply for the work permit to the Ministry of Labour and finally the Residence Permit (RP) from the Passport and Immigration office after issuance of the

work permit.

“A worker could travel to Mauritius only after obtaining the RP and the entire process used to take about 3 months that the project could ill afford,” moans Chirag Singhal, Lead – Railway Systems. “By working smartly, we reduced the initial 3 months for mobilization to 15 working days that went a long way in the project completing on time.”

“A worker could travel to Mauritius only after obtaining the RP and the entire process used to take about 3 months that the project could ill afford. By working smartly, we reduced the initial 3 months for mobilization to 15 working days that went a long way in the project completing on time.”

Chirag Singhal

Lead – Railway Systems

Constructing in the middle of ‘live’ traffic: The project features over 25 rail & road intersections and integrating those into the existing traffic flow and scheme was an uphill struggle. “Effective management of road closures and diversions through planning, communication and coordination with the local authorities and the people limited the inconveniences to an extent,” remarks Pankaj. Some existing major road infrastructure projects where being launched in parallel during the execution phase that called for close collaboration and interface management strategy for compliance

and integration.

Resolving engineering challenges

Constructing the Warren Truss Bridge Deck: From an engineering perspective, the project is complex involving a variety of structures: bridges, flyovers, Warren Truss, TSS building, depot, admin buildings, box culverts, retaining walls, drains, all requiring different Formwork systems for execution. The 62 m long Warren Truss Bridge Deck slab was perhaps one of the most critical structures, for which the shuttering arrangement was critical with the deck around 20 m above the river HFL. “With no possible arrangements for staging or fabricated brackets, we prepared a mock-up of the shuttering at the assembly location to gauge the size and quantity of material required,” informs Lead – Formations, Sanjay Upadhyay. “We identified the difficulties and points of improvement in the designed shuttering scheme and with meticulous planning achieved a cycle time of 3 days. We even reduced material wastage in primary members in the process,” he smiles. Later, the team cast 10 deck slabs at the Rosehill Flyover Extension in a month’s time and casted a 12 m pier in a single pour at the GRNW 6 Bridge, both to meet target schedules for which they won the DELTA Award 2019 from TI IC for ‘Best reduction in cycle time.’

“With no possible arrangements for staging or fabricated brackets, we prepared a mock-up of the shuttering at the assembly location to gauge the size and quantity of material required. We identified the difficulties and points of improvement in the designed shuttering scheme and with meticulous planning achieved a cycle time of 3 days.”

Sanjay Upadhyay

Lead – Formations

Covering the bed: Mauritius’ tropical maritime climate was playing havoc with schedules, with frequent and unexpected rains. Optimum moisture content is required to complete any soil bed from embankment to subgrade top, that is the base of rail track, but the continuous wetting of the beds was causing severe compaction issues for which they evolved a common-sense solution. “We started to cover the concrete bed with 100 m long polythene sheets as soon as it started to rain,” says Deputy General Manager (Civil), Paramjit Singh, “with a small edge drain along the edge of bed to drain off excess water. It worked very well,” he laughs, “much like they do for cricket pitches

when it rains.”

“We started to cover the concrete bed with 100 m long polythene sheets as soon as it started to rain. With a small edge drain along the edge of bed to drain off excess water. It worked very well much like they do for cricket pitches when it rains.”

Paramjit Singh

Deputy General Manager (Civil)

Making the right connections: For Project Manager (Systems), R K Balamurali and the Signalling & Telecom team, the task was to handle 8+ subsystems with subcontractor OEMs, each with diverse scopes, in different stages of integration, supported by remote teams working from different time zones across the globe. “The integration involved almost 1000+ variables across multiple systems for which flexibility and resource management were critical,”

he points out.

“The integration involved almost 1000+ variables across multiple systems for which flexibility and resource management were critical.”

R K Balamurali

Project Manager (Systems)

Onsite lab: Setting up a state-of-the-art Quality control laboratory at site for various disciplines like soil, aggregates, concrete, cement, asphalt etc in line with European standards is completely different than the Indian Standards was a masterstroke, according to Construction Manager (QA/QC), Balasubramanian Mahadevan. “We had ordered the required lab equipment and specifications prepared as per the European standards well in advance and started to use the lab from Day 1 for testing that saved us the cost and delays of relying on 3rd party labs.”

Constructing the iconic Mahatma Gandhi Station: Celebrating Indo-Mauritian relations, the Reduit Station was renamed as the Mahatma Gandhi Station and it was Principal Architect, Sukanta Kumar Saha’s responsibility to adorn it with features that would make the station a fitting tribute to Gandhiji. And, he had only 5 months to make it happen. “Keeping the same basic structure, a few sculptures and architectural elements were incorporated to give it the Gandhian touch,” he observes. Importing the sculptures and architectural features from India gave him sleepless nights but in the end everything fell into place and the inauguration went ahead as planned.

“Keeping the same basic structure, a few sculptures and architectural elements were incorporated to give the Mahatma Gandhi Station the Gandhian touch.”

Sukanta Kumar Saha

Principal Architect

For the entire team, delivering the project as planned has been a huge triumph. “It was important to monitor every execution method at a microscopic level,” sums up Sanjeev, “and we adopted a scenario-based strategy to identify the critical driving factors for each section and tracked critical activities to conclude them which is the reason for our success. At the end of the day, we had the reputation of both our company and country to protect,” he laughs.