MEGA HEAVY CIVIL PROJECTS MAKE SIGNIFICANT HEADWAY IN A CHALLENGING SCENARIO

Ever since, the Mumbai Coastal Road Project (MCRP) took off in late 2018, it has been in the news on the merit of being one of the most ambitious infrastructure projects to tackle Mumbai’s traffic menace. The public has been awed by its magnitude of scope & scale, the challenge to dig various tunnels in one of the world’s most congested cities including a kilometre-long one under the sea for the first time in India and reclaiming land from the Arabian Sea to build the road in an almost entirely marine environment. The project continued to function almost without a break during the lockdown and the two Project Directors, Rakesh Singh Sisodia and Sandeep Singh, for Packages 1 & 4 respectively are focused to keep the ball rolling, and with 25% of the work completed, they are well on track to meet their 2023 deadline.

Mumbai Coastal Road Pkg 1 & 4

Recently, the successful assembly and commissioning of the largest TBM in the country, named ‘Mavala’ – a term drawn from the soldiers of Shivaji, found the project in the news again. An impressive aspect of the project that is being built to last a hundred years is the use of Mono Pile Foundation systems deployed for the first time in India, inspired by the technology used in Dutch windfarm turbines, involving a single structure that reduces installation time & cost and speeds up progress. Another is the use of ‘geotextiles’ that are fine, permeable fabrics laid over the sea wall bedding layer to prevent the fine matter from the reclamation getting washed out into the sea.

MTHL streams forward

Another Mumbai project battling with sea-related challenges is the Mumbai Trans Harbour Link project, another ambitious infrastructure which will be India’s longest sea bridge. It features a 4.7 km long viaduct, 1.6 km long interchange and a 2.5 km at grade section. The superstructure is of three types: 53 spans of the precast segment type, 114 spans that will be cast in situ and another 20 steel spans. The steel spans have two major railways crossings and one highway crossing.

India’s Largest TBM ready to Drive

MTHL 3 – Span Erection

Work stopped on March 23rd but after rigorous follow-ups, the site management received the green signal from the Collector’s Office to proceed, sending the team to commence hectic activity starting with earthwork excavation that required less manpower. Gradually, from April onwards, machinery like excavators, dodgers & dumpers have been pressed into service as work progresses to a planned strategy. “From October 1st, we have been at full strength,” affirms Assistant Project Director, Sanjay Digambar Patil, “with all resources, strictly following all the required safety protocols.” Highlighting on the progress made, Project Manager MTHL 3, Satya Prakash, reels off a few numbers: 76% of foundation, 63% of pier work, 85% of earthwork both to be achieved by June 21 and 49% of the segment casting by October 21.

“From October 1st, we have been at full strength with all resources, strictly following all the required safety protocols.”

Sanjay Digambar Patil

Assistant Project Director, Mumbai Trans Harbour Link Project 1

The precast yard has seen significant progress thanks to strategic planning and some smart execution, remarks Roopesh Kumar Dandapat, Senior Manager – Precast. “Knowing that we had to play catch up, we pressed on the pedal and increased our production of segments from 32 to 52 in a month with 75% of our labour strength,” he says with vigour. “By introducing a gear mechanism to move the segment inner trolley we have improved efficiency with less effort,” he smiles. Senior Engineering Manager (Civil), S R Santhosh Kumar adds that several of their innovations have accelerated progress. “We dismantled the underslung system with the pulling system and are using pre-fabricated cages for the portal beams,” he says. “The inner shutter drive mechanism is another innovation while we are using an improved platform system to stress the underslung system.”

“We dismantled the underslung system with the pulling system and are using pre-fabricated cages for the portal beams. The inner shutter drive mechanism is another innovation while we are using an improved platform system to stress the underslung system.”

S R Santhosh Kumar

Senior Engineering Manager (Civil), Mumbai Trans Harbour Link Project 3

Different people have reacted differently to the pandemic. Construction Manager (Civil), Akhilesh Kumar Singh, considers it as a blessing in disguise as “our dependence on workmen decreased and we adopted more mechanization and automation that have improved our efficiencies.” With continuous follow-ups with the subcontractor and by closely monitoring their deliveries, the team has been able to achieve their monthly billing regularly without impacting progress. The normally stressed admin & accounts departments have the added responsibility of maintaining COVID-19 protocols and keeping people safe. With Mumbai remaining a red zone, the onus on Manager – Accounts, Shaikh Javed Mohammad Akil and his team has been immense. “Our life is all about coordination,” says Javed with a strained smile, “we coordinate with the medical staff for overall health, with JICA for compliance issues, with the government and local bodies of smooth functioning at site, availing of permissions, emergency passes for workmen and a lot more.” Labour strength has been maintained at site according to a pre-planned workman mobilization programme evolved as soon as operations resumed.

Precast elements stacked in the precast yard at MTHL Pkg 3

Recognised as the Best Digitally Enabled site across L&T Construction, MTHL has adopted every relevant digital solution on offer. Apart from conducting regular drone surveys and updating the GIS portal every 3 months with the results of drone photogrammetry, the team has adopted 3D BIM for design, Procube for project monitoring, Asset Insight for P&M, WISA for workmen management, Cynergy for customer interactions and as Digital Officer, Waseem Akram Mittygar adds, “75% of all concrete sourced has been routed through ConEase, fabricated materials are tagged & tracked using E-Tap, we have tracked almost 450 precast segments, the procured material is tracked as well as 100% of our OSD panels.”

“75% of all concrete sourced has been routed through ConEase, fabricated materials are tagged & tracked using E-Tap, we have tracked almost 450 precast segments, the procured material is tracked as well as 100% of our OSD panels”

Waseem Akram Mittygar

Digital Officer, Mumbai Trans Harbour Link Project 1

On track at the RVNL project

Work at Project RVNL Package 2, part of the new 125-km broad gauge line between Rishikesh & Karanprayag in Uttarakhand, started in January 2020 under a pandemic cloud. Although physical activities were stopped, since the project was in the mobilization stage, Project Manager, Prabhu Kumar and his team were able to tick off several activities that did not require physical presence. Contractual submittals like method statements and work programmes were prepared and submitted to the client, RFPs for works were prepared and agencies were finalized after online discussions with the HQ team.

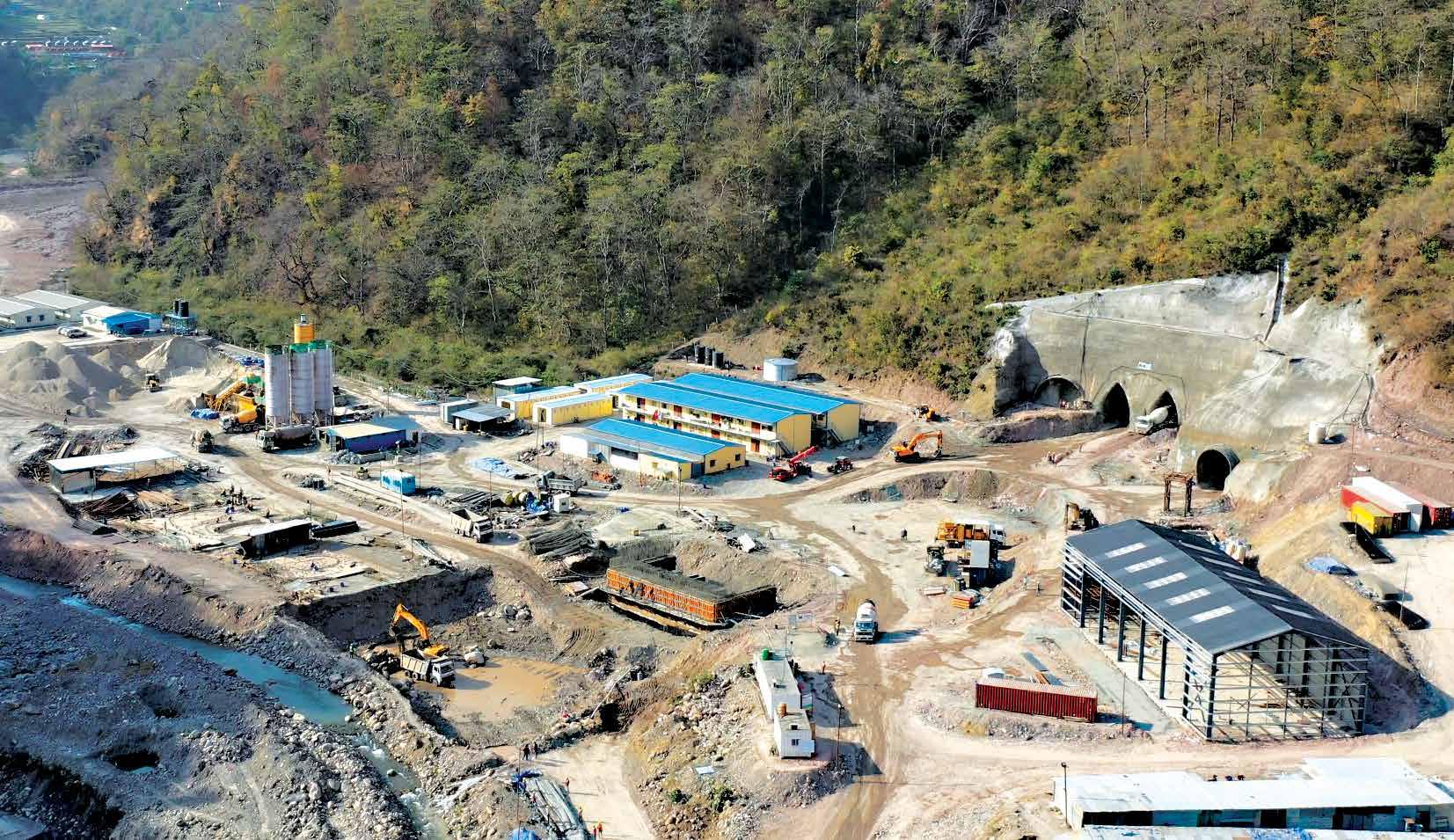

RVNL Pkg 2 – Site Camp and Tunnel Portals

“We finalized and procured client approvals for our check lists and formats for execution and quality checks, finalized vendors and mobilized specialized equipment,” Planning Manager, Vishvamohan Srivastava informs. In addition, the team submitted applications, followed up for statutory permissions, identified, finalized, and deployed staff and mobilized workmen from within the state for the initial works as inter-state movement was restricted.

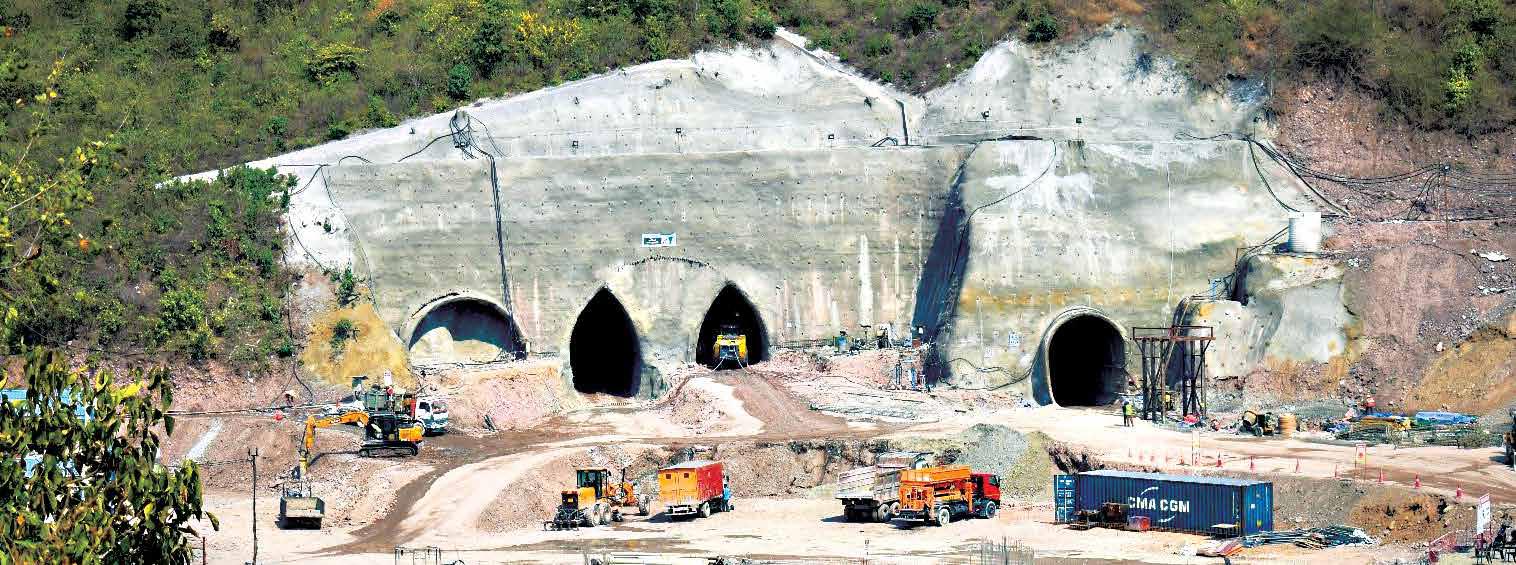

Tunnel excavations in progress

The team hit the tracks as soon as the restrictions were lifted completing the infrastructure facilities and the portals at Byasi and Shivpuri areas and 1,800 m of tunnel excavation by starting ten tunnel faces at four different locations. “We achieved 9,200 cum of concreting (out of total scope of 38,000 cum) for two rail bridges, one road and another minor bridge and RCC retaining wall structures apart from installing & commissioning two 56 Cum/Hr batching plants and one 200 TPH crusher plant,” Prabhu ticks off. In addition, they have commissioned a Project Information & Management System for project documentation and construction monitoring, installed CCTV cameras across the site, a Video Analytical System to track vehicle and people activity inside the tunnel and an IP-based Tunnel Communication System for better communication and data transfer within the tunnel.

“We achieved 9,200 cum of concreting (out of total scope of 38,000 cum) for two rail bridges, one road and another minor bridge and RCC retaining wall structures apart from installing & commissioning two 56 Cum/Hr batching plants and one 200 TPH crusher plant.”

Prabhu Kumar

Project Manager, RVNL Package 2

Led by Sunil Kumar Khatri, In-charge – Tunnel Construction and closely coordinating with other departments, the team commenced tunnel excavation 45 days ahead of the scheduled start date, immediately after completing the portal works. “By closely monitoring productivity and effectively utilizing our resources, we have achieved 60 m of the escape tunnel excavation in a month against targeted progress of 55 m in B3 Class rock,” shares Sunil, “which has been appreciated by our Client too.” For tunnel construction from Adit-2 towards Guller, Shift In-charge, Sujeet Kumar Pandey and team have completed 430 m of tunnel excavation using the NATM method, with limited resources.

“By closely monitoring productivity and effectively utilizing our resources, we have achieved 60 m of the escape tunnel excavation in a month against targeted progress of 55 m in B3 Class rock which has been appreciated by our Client too.”

Sunil Kumar Khatri

In-charge – Tunnel Construction, RVNL Package 2

Liaising with the government authorities took precedence post the unlock for work to proceed which is where Admin In-charge, Ajai Pratap Singh’s expertise came in handy. “We procured permissions to install and commission borewells for construction water, for blasting and did our first blast on August 26th,” he shares. Other permissions Ajai arranged for included short term permits for mining RBM boulders, CTE and CTO for batching plants at Byasi & Shivpuri (first concrete was poured on July 15th), CTE and CTO for 200 TPH crusher, electricity connection from Uttarakhand Electricity Board and permission to operate diesel power generators.

Tunnel portals

RRTS P3L1 takes root in the pandemic

RRTS P3L1 is India’s first Regional Rapid Transit System involving 15.84 km of elevated corridors of a total stretch of 90 kms connecting Delhi & Uttar Pradesh. Project Manager, Subramanyam Itta, received the LOA on March 19th during the lockdown and the NTP (Notice to Proceed) on June 8th when the country was just unlocking posing huge challenges to mobilize men, material, and machinery.

Launching girders at the RRTS project

Staff and workmen mobilization were the first hurdles for Itta, Planning Manager, Avik Datta and Admin & Accounts Head, K Harinarayanan to cross. Travel across the country was still restricted and the client was particular that all COVID-19-related regulations be followed so one person was designated as the pole point to coordinate all movement. Like at other sites, workmen mobilization & retention were challenges with the available local labour too few and raw. Harinarayanan says, “as a team, we formalized and standardized operating procedures, processes, and tools to keep workmen safe, build their confidence through effective, two-way communication and respond to their concerns through flexible adaptation.”

Precast yard set up

Pier works at RRTS

Pile Rigs mobilisation was another major challenge. Mobilizing pile rigs from another project was risky owing to transportation issues and spare parts non-availability, hence they decided to have back-to-back agencies for piling works, thereby transferring the risk (pertaining to skilled labour availability & resource) to the subcontractors. The first pile commenced on July 11th in the viaduct and August 8th in stations against the key milestone target date of October 4th followed by other activities like pile cap & pier works. Developing a customized & operational precast yard in 45 days was another notable achievement as Avik explains. “There was huge demand for fabrication agencies. The moulds had been ordered from HQ at stringent prices & delivery schedules. The drawings & designs were altered that adversely impacted the vendors for timely delivery and quality. To maintain the precasting schedule the team initiated in house modifications, commissioning and started pre-casting of segments to ascertain segment production.”

Heroes leading the charge

N N Munireddy (Deputy General Manager – Mechanical) heads the erection activities for the 15.2 km viaduct that involves 479 spans in 18 months with five launching girders. The first LG was launched on February 23rd and Munireddy is playing a key role to tailor the precast yard to produce 11,000 segments. M Jaya Prakash, Construction Manager (Civil) has the onus for the sub-structure & superstructure works for 5 km of the viaduct and has already executed 25% of his scope including 18,000 m of piling & 133 pile caps, pier & pier caps along with road & media restoration. It is Senior Construction Manager, Sachin Pansare’s responsibility to build the two stations at Murad Nagar and Modi Sagar North. Sachin and his team have already been demonstrating exceptional skill and remarkable progress, focusing on handing over the station to the E&M contractor by January 2022.

The projects of Heavy Civil are huge in size and scope but so are the fortitude and skill of our colleagues to chase progress even in these difficult and unprecedented times. Kudos to all of them!