PT&D IC DELIGHTS CLIENTS BY ENERGIZING THEIR PROJECTS!

TUNNEL ELECTRIFICATION AT THE UDHAMPUR–SRINAGAR– BARAMULLA RAIL LINK PROJECT, JAMMU & KASHMIR

The Government of India has planned a 272 km long railway line from Udhampur to Baramulla under the

Udhampur– Srinagar–Baramulla Rail Link (USBRL) Project as an alternative and reliable transportation system for the people of Jammu & Kashmir. The 112 km long Katra–Banihal section is the missing link that will connect the Kashmir Valley to the rest of India. Declared a ‘national project’ in 2002, this is perhaps the most challenging project undertaken by the Indian Railways postindependence that involves the construction of several tunnels and bridges across extremely rugged and mountainous terrain.

Apart from 38 tunnels, including what will be the country’s longest transportation tunnel, the project also comprises a whopping 927 bridges, among them the iconic Chenab Bridge, the highest railway bridge in the world, and the Indian Railways’ first cable-stayed bridge on Anji Khad, supported by 96 cables. The entire electrical and mechanical

(E&M) scope of the project has been divided into multiple packages.

KRCL Power Distribution Package for Tunnels T1, T2, T8/9, and T10

The package comprises Tunnels T1, T2, T8/9, and T10, with 11 km of main tunnels and 5 km of escape tunnels, located at an altitude of 980 m, and the scope for PT&D IC includes the construction of five 33/11 kV gas insulated substations, eight 11/0.430 kV substations, six of which are inside the tunnel, and HV cabling at the under-construction Anji

Khad Bridge.

Obstructions make for a treacherous, uphill climb

Much like the project’s location, the disruptions have been mountainous too. To start with, the handover of the tunnels in workable condition was delayed. In fact, even today, Tunnel T1 is yet to be handed over, and work on the Anji Bridge is still under progress. Limited availability of space is another issue, with the team having to literally break rocks to forge ahead! “We developed land by hill-cutting and constructing retaining walls ranging from 1.5 m to 8 m height,” reveals Project Manager Dileep Kumar Verma. Access to the site is challenging due to frequent landslides and stone shooting.

Deploying and retaining manpower is tricky due to, among other issues, the local vs. non-local rift and militancy movements. “Skilled migrant workers are reluctant to work in this region,” explains Planning Manager Sunil Kumar Maurya with a serious look. “To retain them, the labour colony is equipped with facilities such as room heaters & blankets for the winter and false ceilings to reduce the summer heat, with police night patrolling, organized with the help of the local administration. We have also encouraged localization by asking subcontractors to engage more than 50% of local labour to avoid unrest.”

“To retain migrant workers, the labour colony is equipped with facilities such as room heaters & blankets for the winter and false ceilings to reduce the summer heat. We have also encouraged localization by asking subcontractors to engage more than 50% of local labour. ”

Sunil Kumar Maurya

Planning Manager

Tray and cabling work inside Tunnels T8/9

Complications of all shapes and sizes

To add to the space constraints, the tunnels are of varying sizes and non-uniform shapes: some D-shaped, some elliptical, some modified horseshoe, and so on. Various agencies are involved, with the engineering, interface, and installation of equipment inside tunnels requiring precision to avoid any infringement with the schedule of dimension (SOD) of the train. But thanks to careful collaboration with the agencies, the process has been smooth. “We closely coordinate with the detail design consultants (DDCs) and other agencies for timely resolution of any infringements to avoid rework,” confirms Construction Manager Arvind Singh Panwar. “Before the start of every activity inside the tunnels, we perform a mock-up to ensure suitability for fitment.”

“We closely coordinate with the detail design consultants (DDCs) and other agencies for timely resolution of any infringements to avoid rework. Before the start of every activity inside the tunnels, we perform a mock-up to ensure suitability

for fitment.”

Arvind Singh Panwar

Construction Manager

Laying the 33 kV cable weighing 20 kg/m at a height of 6 m inside the tunnel was a tall ask, for which customized scaffolding was used. “We have established a full-fledged fabrication yard for TMT and fire protection pipe for cutting, bending, grooving, and painting to ensure better quality, safety, speed and to minimize scrap,” remarks Sunil.

The USBRL is a complex project with various systems and two DDCs to verify engineering drawings and vendor documents. “The digital tool ‘Align’ has worked wonders for us to microplan and monitor the progress of engineering, procurement, and construction,” mentions Arvind with a smile. Other digital solutions include

M-power, WISA, QIR, and Shield apps.

The hilly terrain and tunnels call for special attention towards workmen safety. “We provide regular onsite

activity-specific training on different aspects of safety while working near hilly areas and inside tunnels,” elaborates

EHS In-charge Sanjeev Kumar. “Two-wheeler movement at site is banned and monitored meticulously. We also regularly monitor oxygen levels inside tunnels to ensure safe working conditions that has won us a RoSPA Gold in 2022!” His delight is obvious.

“We provide regular onsite activit-yspecific training on different aspects of safety while working near hilly areas and inside tunnels. We also regularly monitor oxygen levels inside tunnels to ensure safe working conditions that has won us a RoSPA Gold in 2022!”

Sanjeev Kumar

EHS In-charge

T5P1 33/11 kV GIS Portal Substation and Firefighting Pump House under construction

Efforts well recognized

“From the beginning, we have maintained positive cash flow and negative working capital by timely invoice certification and collection from the customer,” beams Project Accountant Gopi Marripudi.

The client has been lavish in their appreciation for the team’s efforts to tackle the difficult obstructions. “The L&T team has made an outstanding contribution in implementing labour laws and statutory compliances despite several unfavourable conditions, particularly during the COVID-19 pandemic,” the Regional Labour Commissioner of Jammu had applauded when presenting the team with an Appreciation Certificate.

“We have achieved 40% of project progress and are targeting completion by June 2023 through micro-planning, constant reviews, and training engineers to execute multidisciplinary activities by deploying the available digital tools,” Dileep says, signing off with a confident thumbs-up.

“We have achieved 40% of project progress and are targeting completion by June 2023 through micro-planning, constant reviews, and training engineers to execute multidisciplinary activities by deploying the available digital tools. ”

Dileep Kumar Verma

Project Manager

KRCL Power Distribution Package for Tunnels T3 and T5

The E&M work for this package includes the supply, erection, testing, and commissioning of 33 kV and 11 kV HT power cable network, GIS substation, DG sets, tunnel ventilation system, tunnel lighting, SCADA, and firefighting systems for Tunnels T3 and T5, between kms 39 to 52 on the Katra–Dharam section of the USBRL.

Meticulous measures employed

The project team began their survey jointly with the Konkan Railway Corporation Limited (KRCL) to identify locations

for the substation and firefighting buildings. “We finalized the design after several visits considering the space constraints and seismic zone-V,” explains Planning Head Tanmay Dwivedi. “551 detailed design/engineering drawings were prepared with each minute detail captured, checked, and approved by the client.”

“We finalized the design after several visits considering the space constraints and seismic zone-V. 551 detailed design/engineering drawings were prepared with each minute detail captured, checked, and approved by the client.”

Tanmay Dwivedi

Planning Head

Automation is propelling project progress: STAAD.Pro for building designing, DIALux for lighting, and Acoustic Study

for designing the public address system. “The entire system is so designed that all the tunnel utilities and substation equipment can be controlled through a SCADA system from anywhere, be it a SCADA control room, a railway station control room, or the J&K railway HQ,” clarifies Project Manager Nandalal Chandra.

“The entire system is so designed that all the tunnel utilities and substation equipment can be controlled through a SCADA system from anywhere, be it a SCADA control room, a railway station control room, or the J&K railway HQ.”

Nandalal Chandra

Project Manager

A well-strategized plan

Owing to the tough terrain, Tanmay and team have planned the material on a stagewise basis, monitored as per the execution schedule. “By coordinating with all the stakeholders and ensuring positive cashflow throughout the project cycle, we have managed to meet all project deliverables on time,” explains Tanmay.

The unavailability of skilled labour in Jammu & Kashmir has been addressed by arranging a labour colony with all basic facilities to retain workmen, which has also helped maintain quality standards. “We have ensured that the materials delivered at site are as per approved designs and the GPRS Tunnelling Protocol (GTP) and have implemented quality standards as per the client’s approved field quality plan and method statements,” says Quality Head Vishnu Kumar emphatically.

“We have ensured that the materials delivered at site are as per approved designs and the GPRS Tunnelling Protocol (GTP) and have implemented quality standards as per the client’s approved field quality plan and method statements.”

Vishnu Kumar

Quality Head

A Hazard Identification and Risk Assessment (HIRA) workshop was conducted at the beginning. EHS Head

Nishant Kumar and team, through continuous monitoring, ensure that all identified risks are mitigated well ahead of time. “From the word ‘go’, all SOPs related to COVID-19 were implemented at each level,” elaborates Nishant. “Hence, we were able to continue the project work even during peak COVID waves.” Nishant and team regularly monitor all PTPs and related observations through the Shield app. A safety culture has been inculcated at site through periodic physical training as well as VR training.

On the digital front, project progress is being tracked using the Align tool, QIR, Shield apps and WISA and the project has migrated to PROnTo for centralizing the planning module.

T3P2 33/11 kV GIS Portal Substation under construction

Providing value for the client

“The client has appreciated us for maintaining excellent safety and quality standards in the project,” signs off Nandalal. “By maintaining good relationships, we have met all our financial targets including settlement of price variation claims.”

Speaking of client delight, Jitendra Kane, Assistant Electrical Engineer (Project), Konkan Railway, Reasi, said it best when appreciating L&T’s work at the project: “Resonating with their brand image, we find that despite the tough terrain, adverse weather conditions, and the tough geology of J&K, L&T’s performance, quality of work, and project management have greatly contributed to the esteemed project of connecting Kashmir to the rest of India. L&T is rightly labelled as nation-builders!”

REPLACEMENT OF OLD AND OBSOLETE SUBSTATIONS IN MAA REFINERY, KNPC, KUWAIT

The Kuwait National Petroleum Company’s (KNPC’s) Mina Al Ahmadi (MAA) refinery was built in 1949 with a capacity of 25,000 barrels per day (bpd) to cater to local demands. After two phases of modernization over the years, its processing capacity has increased to 466,000 bpd. In 2020, PT&D IC was awarded the project to provide a new network of distribution substations with the latest technology by replacing the 9 existing substations at the MAA refinery and the North Pier area operating with old/obsolete switchgears and systems that were built in 1981.

The scope of work and new facilities includes the construction of 3 blast-resistant and 2 non-blast-resistant buildings; supply, installation, and commissioning of 11 kV switchgear of 50 KA fault level with Is-limiter and Ultra-Fast Earthing Switches; real-time study of the electrical network using E-TAP online; sequential load transfer of 1,500 active loads from old to new substations; and electrical and instrumentation cable laying of over 350 km, among others.

An area rife with difficulties

To begin with, the site location was challenging. Being the largest in Kuwait contributing significantly to the national economy, the refinery is a strategic asset situated in a high-security zone with restricted access. In addition to the presence of several hydrocarbon processing units and off-site facilities, the refinery is prone to hydrocarbons and

H2S gases exposure and the salt-laden sea air is corrosive. There were other severe constructability restrictions caused by cables, fire hydrants, and other process unit facilities in and around the site.

The critical load-shifting activities had to be carried out without shutting down the plant, and the work at the North Pier was 1.5 km offshore. With commodity prices skyrocketing and a global shortage of electronic components, containers, and vessels, the project team was severely tested to manage costs and timely deliveries.

Tackling issues prudently

Taking one thing at a time, the project team started by negotiating the schedule to begin from September 2020, against the original schedule of May. “This helped us gain an advantage to identify resources early,” says Project Manager Ashwani Kumar Tyagi. “We got a head start to carry out survey activities, fulfil advance prerequisites, and ensure availability of key personnel right from Day One.”

“We got a head start to carry out survey activities, fulfil advance prerequisites, and ensure availability of key personnel right from Day One.”

Ashwani Kumar Tyagi

Project Manager

For manpower mobilization, the team was well prepared. The Kuwait government had stopped issuing visas to contractors to prevent the spread of the pandemic therefore the team took the client’s help to mobilize L&T manpower. “We were able to utilize several positions like Procurement, Planning, and Costing Engineers from other L&T projects, saving indirect cost,” reveals Planning Lead Vishal Nandkumar Raje. “This continued until December 2021 when Kuwait and India lifted their travel bans by which time, we had already completed 50% with minimal resources!”

“We were able to utilize several positions like Procurement, Planning, and Costing Engineers from other L&T projects, saving indirect cost. This continued until December 2021 when Kuwait and India lifted their travel bans by which time, we had already completed 50% with minimal resources!”

Vishal Nandkumar Raje

Planning Lead

HV Switchgear

Delays were inevitable during the pandemic, and the team proactively conducted a workshop with KNPC to reduce the customer approval cycle time. “We merged the approval processes for RFQ and TBE,” explains Vishal. “All documents relating to a particular equipment were submitted together, which significantly reduced the approval time.” To tackle the high commodity prices and logistics challenges, the team adopted special approvals from the client:

- DG (change in COO): The client accepted material from component manufacturers in the approved CEC/VEC list where the assembly was happening outside the component manufacturer’s location.

- Cables (change in insulation material): The client was briefed about the benefits of a new material, Hyperon, over lead, the material prescribed in the specification.

- DC UPS (change in battery rating): A deep dive by the technical committee revealed that the initial specifications of an 8-hour backup would waste natural resources and money. The client accepted the reduction of battery backup to 1 hour, sufficient for the smooth running of the system.

- HVAC (change in SC methodology): The contractual requirement was to order HVAC as a single package, but the client allowed L&T to integrate HVAC components.

These changes helped the project get lower vendor quotes and order placement. “We solicited and obtained unit-rate validities for extended periods,” adds Vishal, “and expedited orders by following up directly with the sub-vendors when needed.” The team took the support of L&T offices in nearby countries for manufacturing and conducting stage-wise inspections. The client too helped mount necessary pressure on vendors whenever required.

On the subcontracting front, the building work was broken down into blast-proof and non-blast-proof buildings to ensure sufficient availability of manpower and resources.

Vishal throws light on their plan: “We specifically targeted companies that were not already overloaded with orders with idle resources in Kuwait. It also helped us obtain special rates from subcontractors that were lower than our in-house working rates,” he says triumphantly.

A strategic approach

The project commenced with SMART goals defined and dedicated teams deployed for critical path activities. Adequate funding was ensured to avoid slippages in activities owing to budget constraints. “We conducted a risk analysis at initiation to identify issues early and resolve them immediately before they could affect the project,” says Quality Head Vasudevan Jayaraman, “and continually monitored subcontractor productivity through daily progress reports (DPRs).”

A Critical Task Risk Assessment (CTRA) was conducted for critical activities to identify risks and brainstorm over feasible resolutions.

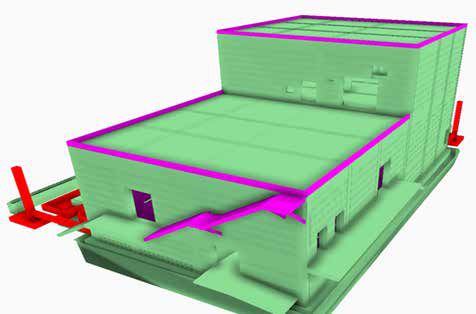

PARIMAAN model – M64A Substation

In terms of material management, Ashwani Kumar and team have implemented technologies such as connected drums, “to reconcile cable drum lengths and minimize cable scrap,” he explains. “Similarly, cross-docking project equipment directly on their designated foundations has helped avoid double handling of material. We also link monthly reconciliation statements with progress measurements of subcontractors.” The team has managed to get the central storage yard allocated within the MAA refinery premises, even though it was not a contractual obligation.

The Align tool monitors real-time monitoring, and with the Quality and Safety apps, learnings from one location help implement corrective measures in others. “Project data is stored on a shared server with access control,” EHS Head Sameer Dawood Gangrekar says. “We have developed 3D, 4D, and 5D models for clash checking and monitoring,

and virtual reality for HSE training.”

Night view of the M61A/M62A/M63A Substation

A happy client, a happy project

“Our client, KNPC, has recommended us for the HSE Rolling Trophy, which is currently under management approval,” Sameer shares proudly. The project has achieved one million safe manhours without LTI and has successfully completed a ‘SAFOP’ workshop.

The client is regularly apprised on progress updates. “At weekly review meetings, the customer can record their concerns and hear our plan to address routine issues,” spells out Vasudevan. “From time to time, additions/deletions

to the project’s scope are highlighted through Change Order Requests and amicably agreed upon.”

Over the course of the project, the team has maintained positive cash flow and reduced the collection cycle from the contractual 30 days to 10–15 days. “We have improved profitability and job margin and have maintained negative sales over invoice from commencement, which shall continue till completion,” remarks Ashwani Kumar with a confident grin.