TI IC CONTINUES TO CONTRIBUTE TO

NATION-BUILDING IN THE FACE OF

THE PANDEMIC!

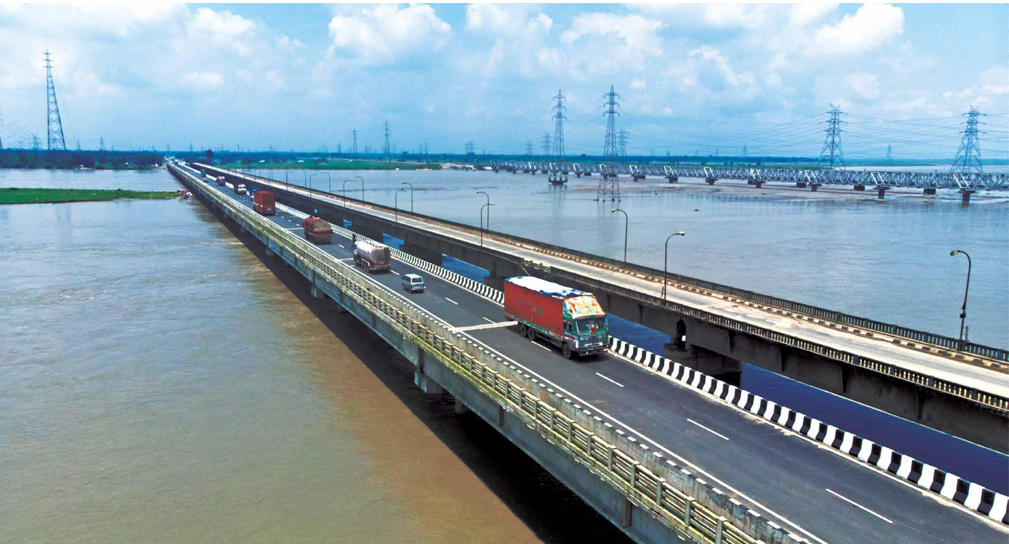

With tensions brewing at the borders with the Chinese, logistics of the Defence Forces have assumed vital importance. The 1.0006 km long major bridge over the river Teesta being constructed by the Ghoshpukur-Salsalabari Road Project (GSRP) team of RREC (TI IC) was to serve as a vital and only link to the North Eastern States and provide easy connectivity to the Hansimara Indian Air Force base. Apart from this national and strategic significance, the completion of the bridge was important for Project Manager, Niloy Mukherjee, to achieve his challenging Q4 target and move towards completing and handing over his project.

Stopped in their tracks

COVID-19 and the national lockdown from end-March 2020 stopped progress in its tracks. “We had already completed 76.45% of the project with only some finishing works and the activities from our Q1 plan pending were slope and embankment protection works, constructing median and shoulder drains, fixing metal crash barriers and guardrails,” Niloy recalls grimly. There was also the threat of a long, severe monsoon during which the river is usually aggressive and unpredictable.

Flyover at Ghoshpukur

“The work was closely monitored through several video calls with our site supervisors. Every machine, every workspace, every employee was screened, tested, sanitized, and checked at regular intervals.”

Niloy Mukherjee

Project Manager,

Ghoshpukur-Salsalabari Road Project

However, unfazed by these setbacks, the team quickly reorganized themselves and formulated detailed alternative plans to resume operations as the customer, National Highways Authority of India (NHAI), indicated a possible relaxation of the lockdown by end-April. “To start with, our EHS & HR teams along with the site leadership drew up a comprehensive SOP that was shared with all our employees, workmen, and other stakeholders,” informs Planning Manager, Aneesh Sharma. Training sessions were scheduled for the workmen prior to resumption, a system for stringent screening and monitoring finalized, personal protective and sanitizing equipment procured, and quarantine and isolation facilities arranged at site. Shifts were reworked with one-hour gaps to ensure that groups did not meet or mingle, and workmen were constantly counselled about the pandemic, its symptoms, the various precautions to be taken.

Section of the East-West Corridor of Ghoshpukur-Salsalabari Road Project

Getting back into the swing of things

“We got a lucky break when the government announced a relaxation in the lockdown restrictions which was followed by a NHAI circular that activities could resume on April 20th,” says a relieved Niloy. “We resumed operations the very next day following our stringent action plan and SOPs.”

“In consultation with the HQ admin team and the local administration, we decided to engage locally available workmen, who were thoroughly screened and tested before starting work.”

Aneesh Kumar Sharma

Planning Manager,

Ghoshpukur-Salsalabari Road Project

Almost immediately, they encountered their first roadblock: lack of labour. From an initial strength of about

900 workmen at site, 300 decided to return to their hometowns as soon as the lockdown was announced. The 600 who chose to remain were well looked after but with the relaxation of travel restrictions, 250 left immediately and the site was forced to resume operations with a meagre strength of 350 workmen. With a mountain to climb and the threat of the approaching monsoon looming, the team did not waste any time ruing about the situation but developed alternate plans to mobilize labour.

“In consultation with the HQ admin team and the local administration, we decided to engage locally available workmen,” says Aneesh, “who were thoroughly screened and tested before starting work.” Another step they took was to bring back some of the skilled labour in groups considering the capacity of the quarantine centres. These workmen underwent 7 – 14 days in quarantine before re-joining after the mandatory screening and checking. The team’s concerted efforts won them a Certificate of Appreciation from NHAI. While the engineers worked in allocated shifts, the fresh workmen were trained on the job. Niloy agrees that the onus was much greater on the team to work faster and safely. “The work was closely monitored through several video calls with our site supervisors. Every machine, every workspace, every employee was screened, tested, sanitized, and checked at regular intervals. We also encouraged employees to use digital platforms as much as possible to reduce physical contact and thereby the threat of infections.”

The bridge was completed before the first rains much to the satisfaction of NHAI and India’s Defence Forces though Niloy, Aneesh and team cannot afford to relax as they have new mountains to climb before delivering their project.

Pavement Quality Concreting at the Mumbai Nagpur Expressway Project

Over at the Mumbai Nagpur Expressway Project – Package 10, the team successfully procured permissions from the District authorities to conditionally resume operations on April 4th itself. Project Manager,

Rongali Srinivas’s team got to work in earnest, though labour proved to be their major stumbling block too. Although many chose to stay put at the site during the lockdown, several left as soon as the relaxations were announced. “We had to mobilize a whole new set of workmen for the months of May and June,” Rongali shakes his head, “but thanks to the untiring efforts of the HR and time office teams, we mobilized 1,400 new workmen from across states.” Closely coordinating with the subcontractors and the State authorities, they successfully brought back some workmen and put them to work after the requisite quarantining, medical check-ups and screenings. Planning Manager, Abhinav Agarwal’s chips in, “We have been strictly following all the Government instructions and advisories which is why, touch wood, we have not had a single positive COVID case in our labour camps.”

“We had to mobilize a whole new set of workmen for the months of May and June, but thanks to the untiring efforts of the HR and time office teams, we mobilized 1,400 new workmen from across states.”

Rongali Srinivas

Project Manager,

Mumbai Nagpur Expressway Project – Package 10

Reinforcement tying work at the Mumbai Nagpur Expressway Project

Section of Mumbai – Nagpur Expressway Project

“We have been strictly following all the Government instructions and advisories which is why, touch wood, we have not had a single positive COVID case in our

labour camps.”

Abhinav Agarwal’s

Planning Manager,

Mumbai Nagpur Expressway Project – Package 10

Rongali had to catch up on lost time as well as complete work to the extent possible before the monsoons broke. “We rescheduled our plans and concentrated more on precast activities like girder casting, RE and boundary wall panels. We did finishing road activities like mechanical works, shoulder filling, slope dressing, toe drains and median drains wherever the road top was completed.” He has reason to smile because the team has achieved 93% of targeted invoicing and are now gunning to complete the project before the scheduled completion date.

“In July, we started a new activity – PQC – and completed a length of 1.62 km of the

8-lane carriage way.”

Kamal Kishore Singh

Project Manager, Mumbai

Vadodara Expressway

Re-commencing work on April 21st with the available work force, the team at the Mumbai Vadodara Expressway project was able to execute concreting activities to the tune of 5,600 cum in May and 16,200 cum in June involving structural concrete, precast concrete, DLC and the like. “In July, we started a new activity – PQC – and completed a length of 1.62 km of the 8-lane carriage way”, says Project Manager, Kamal Kishore Singh who along with Planning Head, Shashikanta Tripathy are glad that all the planned work has been completed without compromising on the cash flow.

“Despite all the challenges posed by the pandemic, we completed the depot in true L&T style and successfully unloaded

7,000 MT of rails.”

Vikram Kohli

Project Manager – CP 303 Project

Back on the rails

Completing the Gulaothi Yard Depot was a huge ask for the CP 303 project team being the only depot of its kind across all DFCCIL projects where rails can be received directly through rail racks. Project Manager, Vikram Kohli, is delighted with his team. “Despite all the challenges posed by the pandemic, we completed the depot in true L&T style and successfully unloaded 7,000 MT of rails.”

Completed section of the Mumbai – Vadodara Road

There was, however, no escaping the vexing labour issue even as they resumed operations on May 6th following all the mandatory SOPs. Increasing their labour strength from 200 to 750 by June 15th and enhancing the earthwork teams are triumphs for Planning Manager, Mayank Varshney. Most of the works are machine-oriented that are outsourced to subcontractors on a back-to-back basis though remobilizing them post the lockdown has been an uphill task. Ensuring continuous supply of bulk materials has been another challenge as all interstate movement was prohibited. “We had to procure special passes from the district administration and the Railways to keep things moving,” Mayank explains.

“We were able to ramp up operations and achieved 90% peak progress in May and did even better at 110% in June compared to last year.”

Vikram Kohli

Project Manager – CP 303 Project

Vikram’s broad smile says that all their effort was worth it. “We were able to ramp up operations and achieved 90% peak progress in May and did even better at 110% in June compared to last year.” Rapid progress has translated into better invoicing resulting in improved collections. “We have followed our CEO & MD’s advice to chase cash,” he signs off, his attention already on to his next task.

“COVID-19 disrupted our operations significantly. However, we have been able to overcome the challenges and resume work by May. Things have gradually returned to normal and our team is confident of achieving our targets.”

R K Bansal

Head – Road & Runways BU

“Keeping project sites safe and functioning in high gear from a stalled situation have been extremely challenging,” remarks R K Bansal, Head – Road & Runways BU, with a grimace. “We all talk of the new normal but implementing it with the workmen at site has been really tough as it is completely out of their character to wear masks, keep distance, maintain cleanliness and the like. Getting labour has been very difficult and mobilizing skilled labour even more so. A lot of the labour being mobilized these days is raw who need to be thoroughly trained before they start contributing meaningfully. At the same time, speedy progress is imperative. We have finally managed to reach 100% labour strength at all our project sites. COVID-19 disrupted our operations significantly. However, we have been able to overcome the challenges and resume work by May. Things have gradually returned to normal and our team is confident of achieving our targets,” he rounds off with a refreshing air of positivity.